Making clay pipes

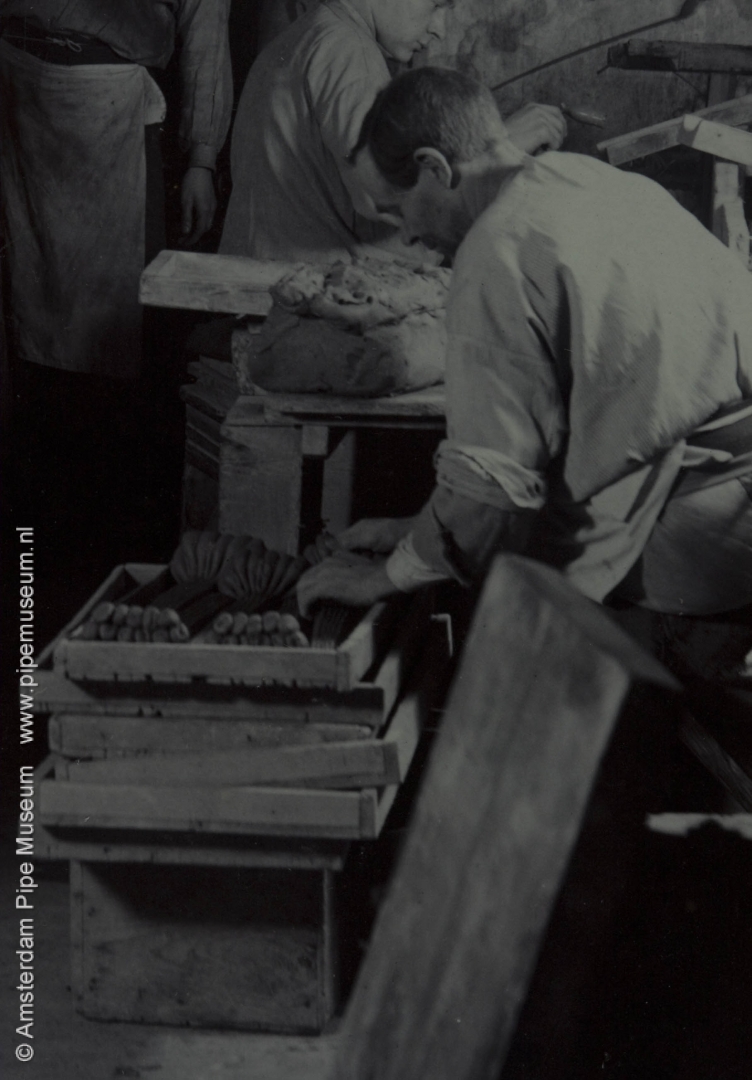

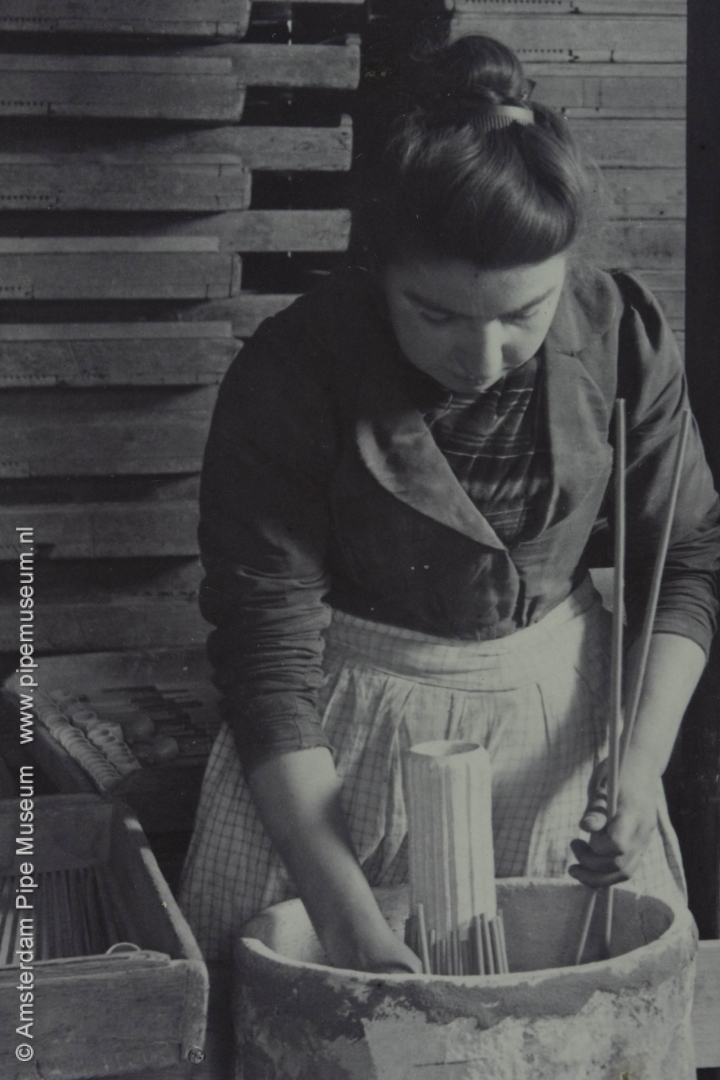

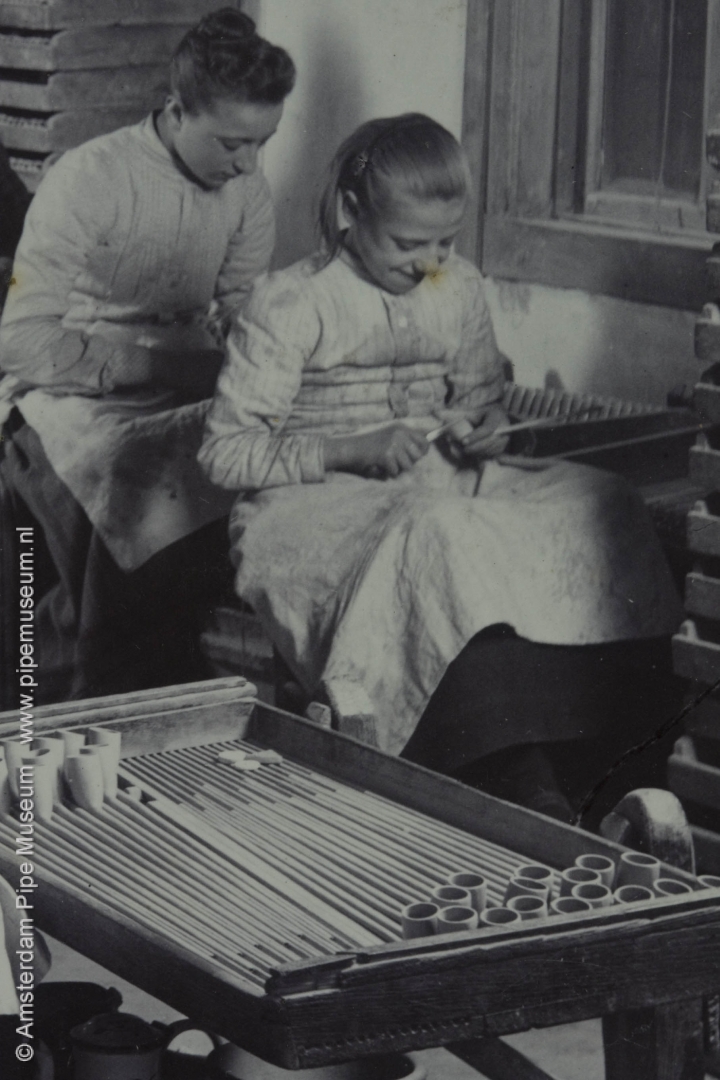

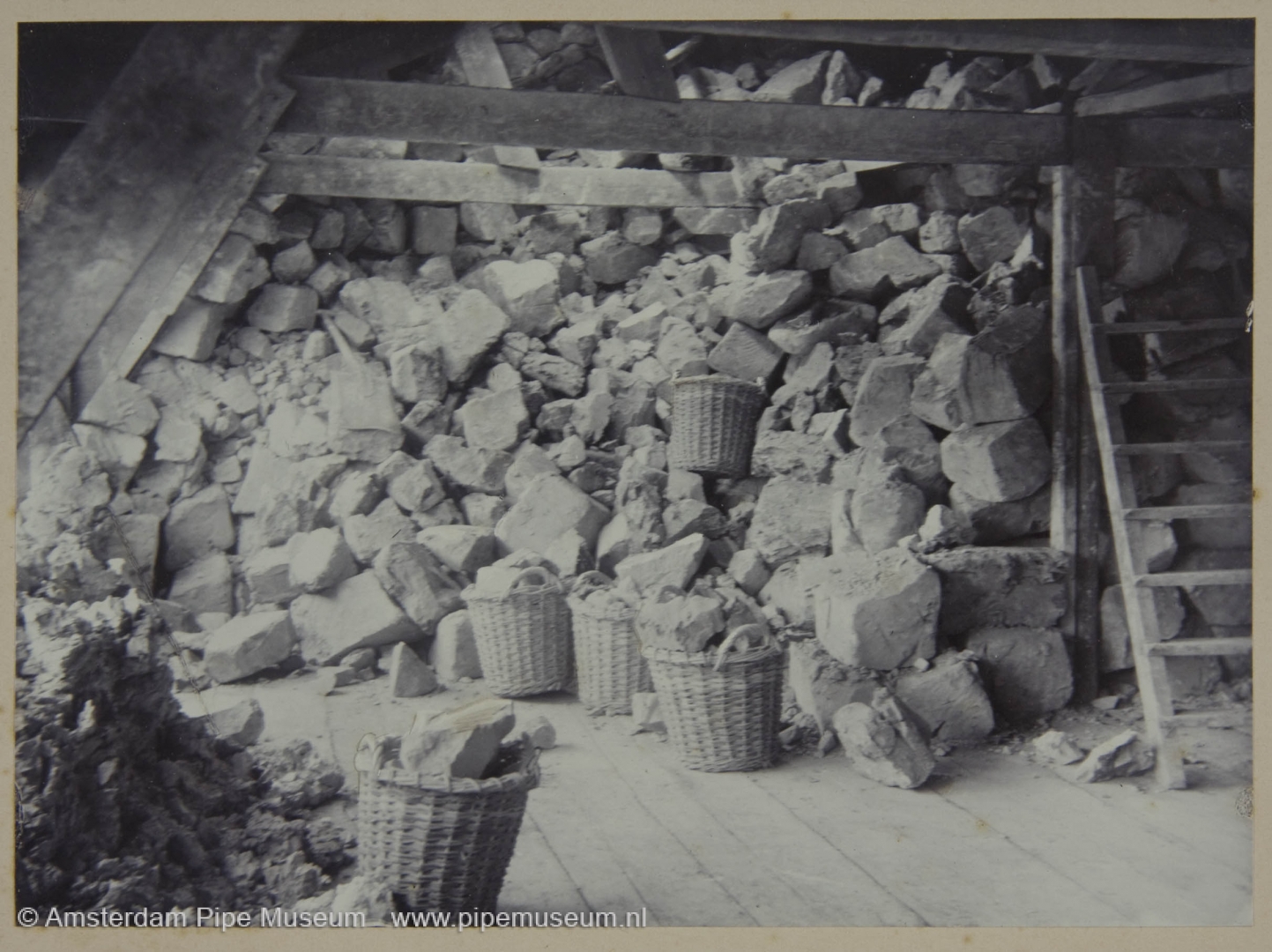

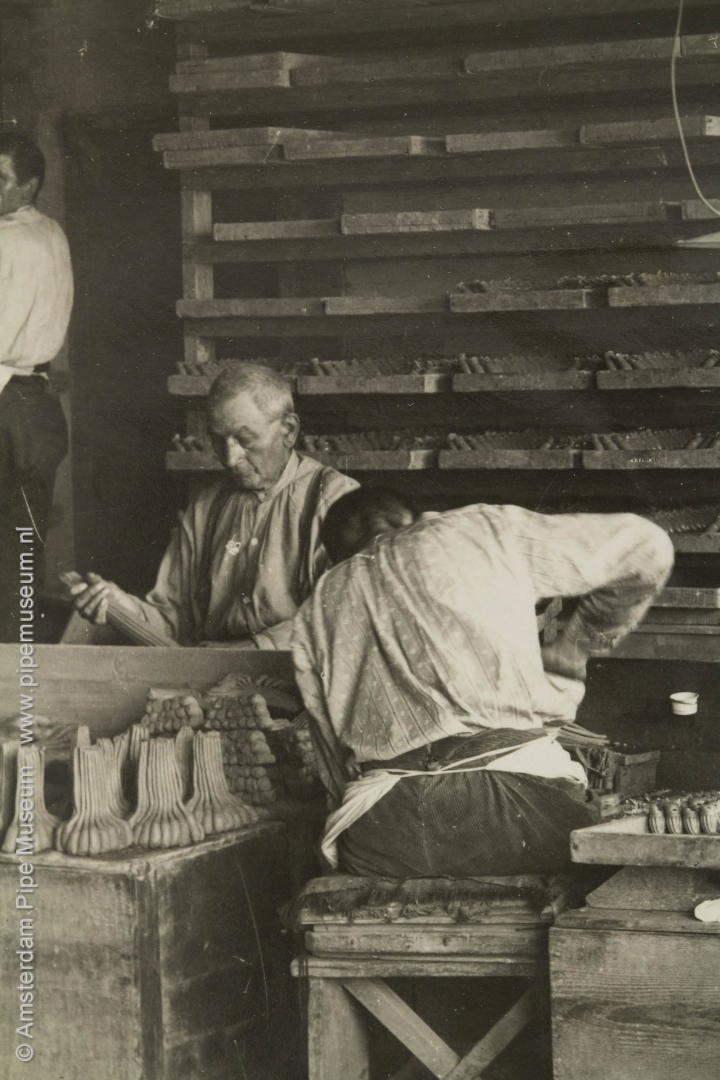

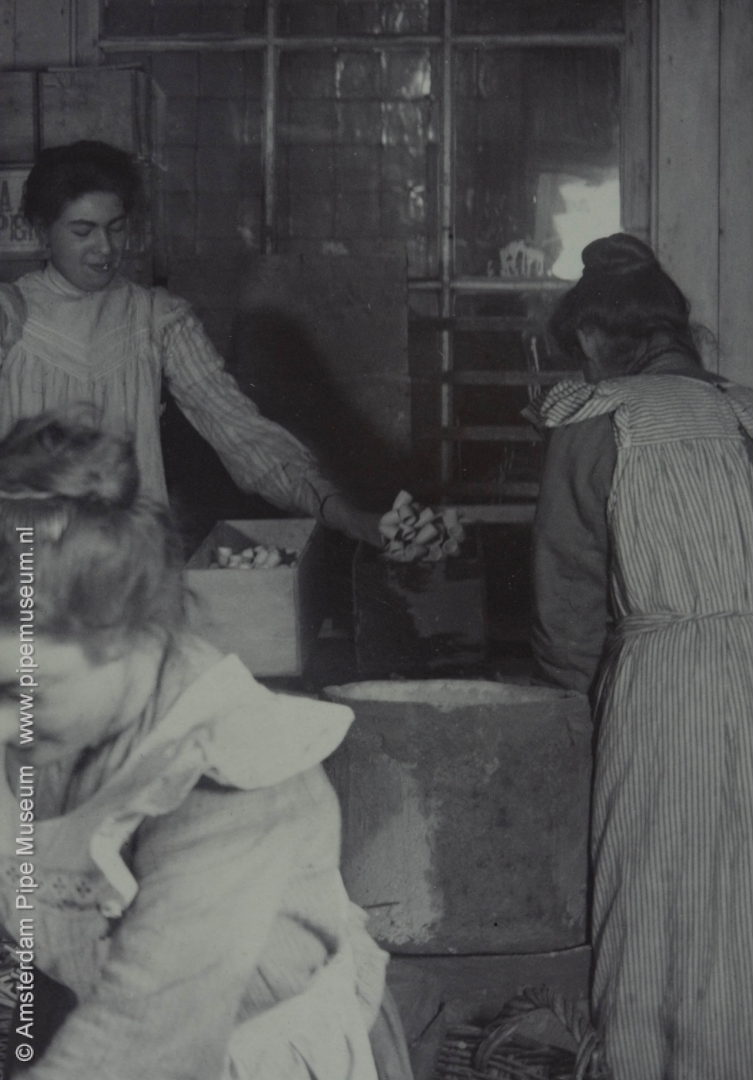

Making clay pipes is a craft that hardly changed in the Netherlands from 1600 to 1960. Here it is depicted in photographs from around 1900. The raw material for the clay pipe is white-backing clay, referred to as pipe clay. Before the actual pipe making can start, the clay is kneaded into a smooth homogeneous mass. The first action after that is to pre form the pipe clay into rolls in which the basic shape of the pipe is already present. The rolder who does this is often an apprentice. After the rolls have dried for a few days, the real pipe making follows.

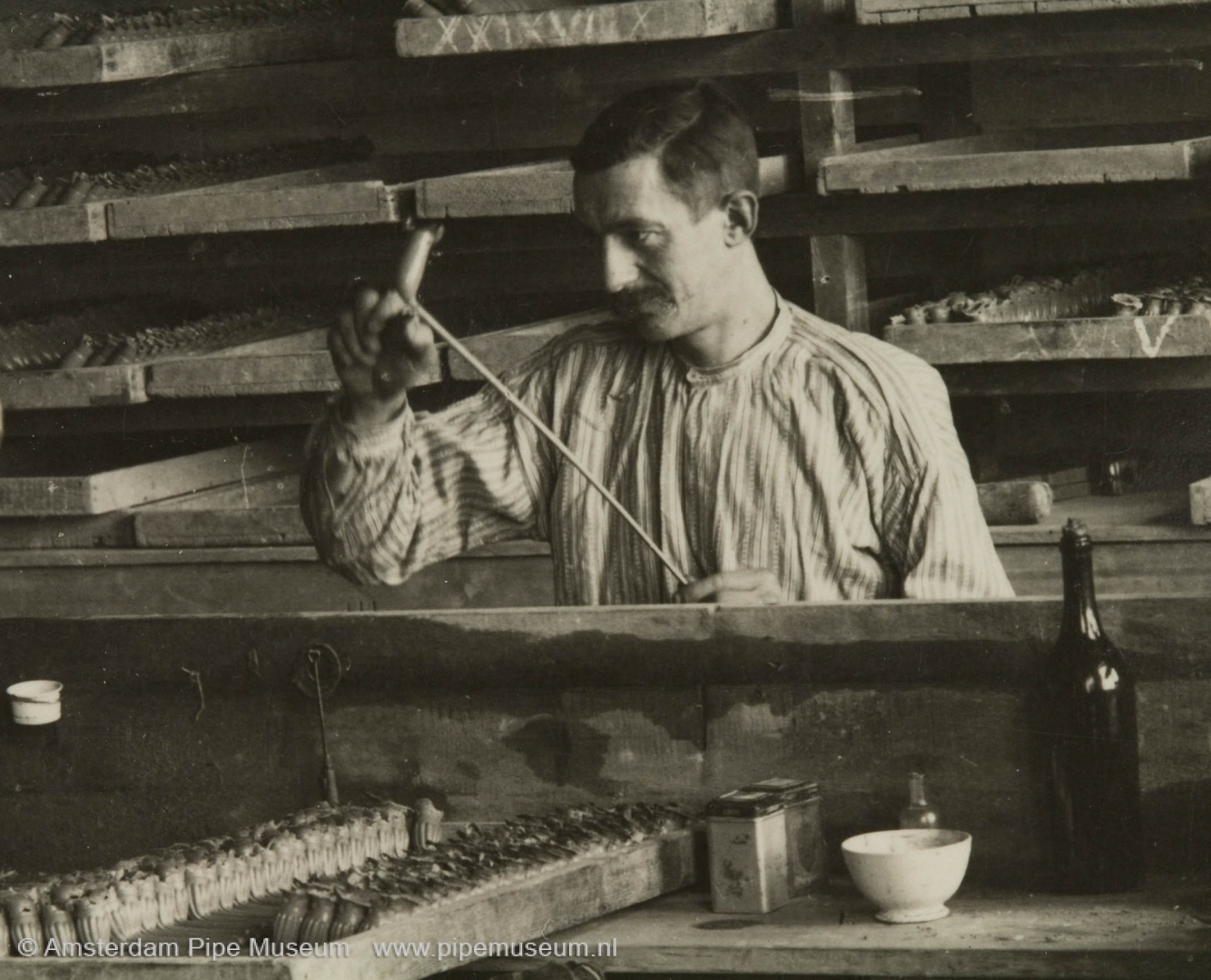

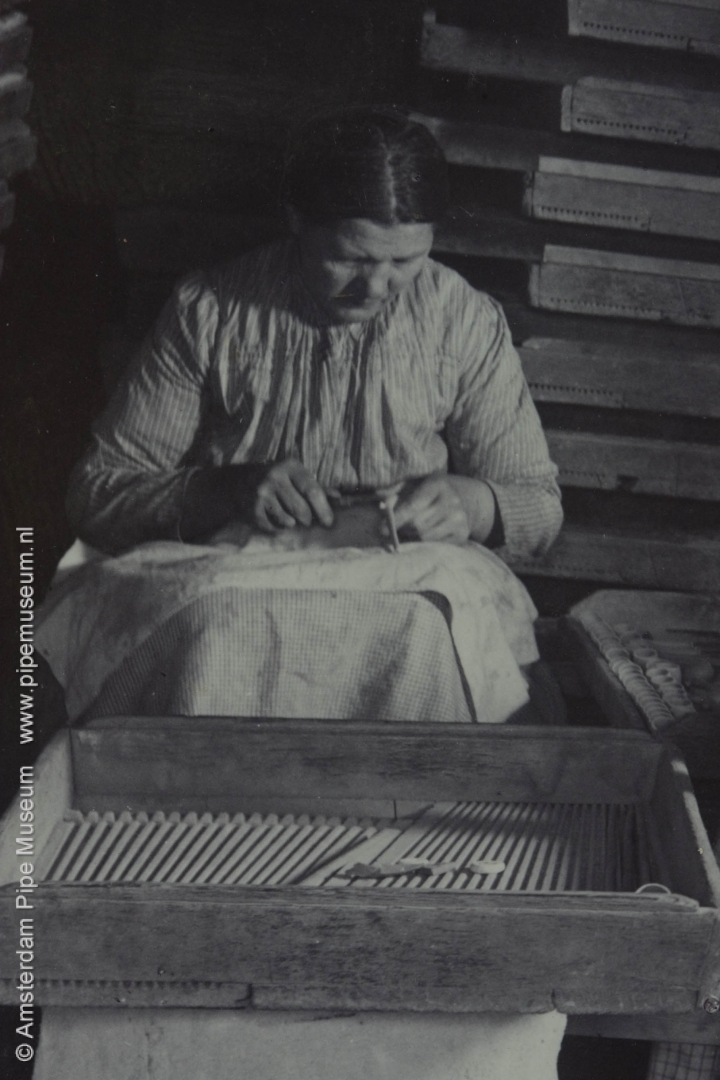

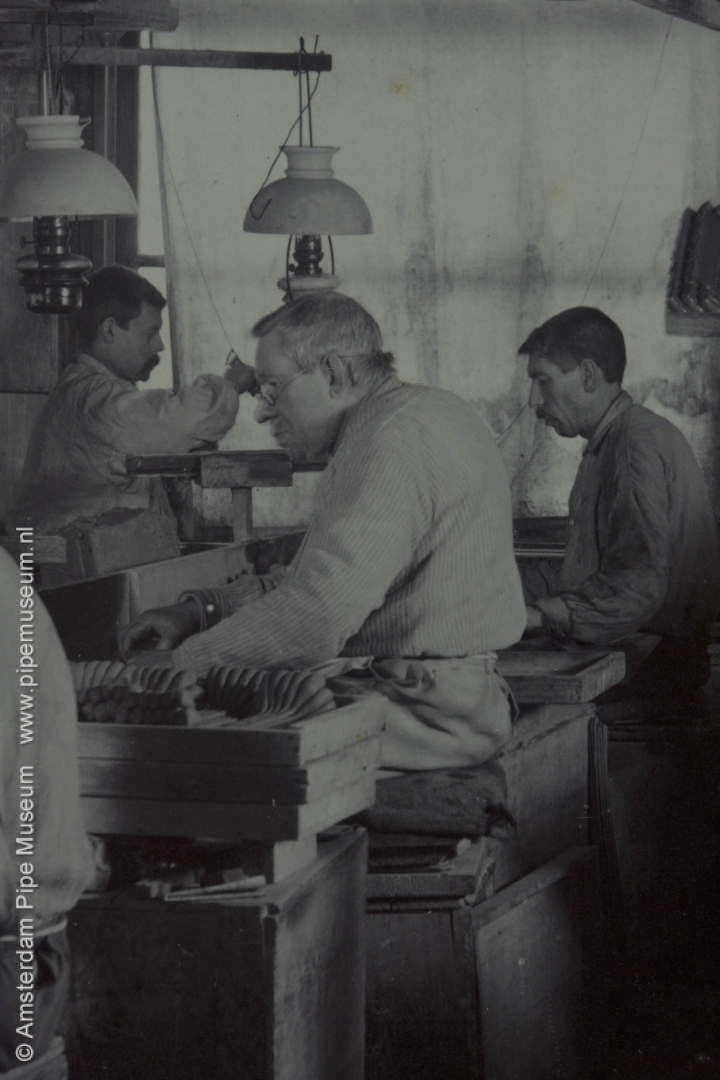

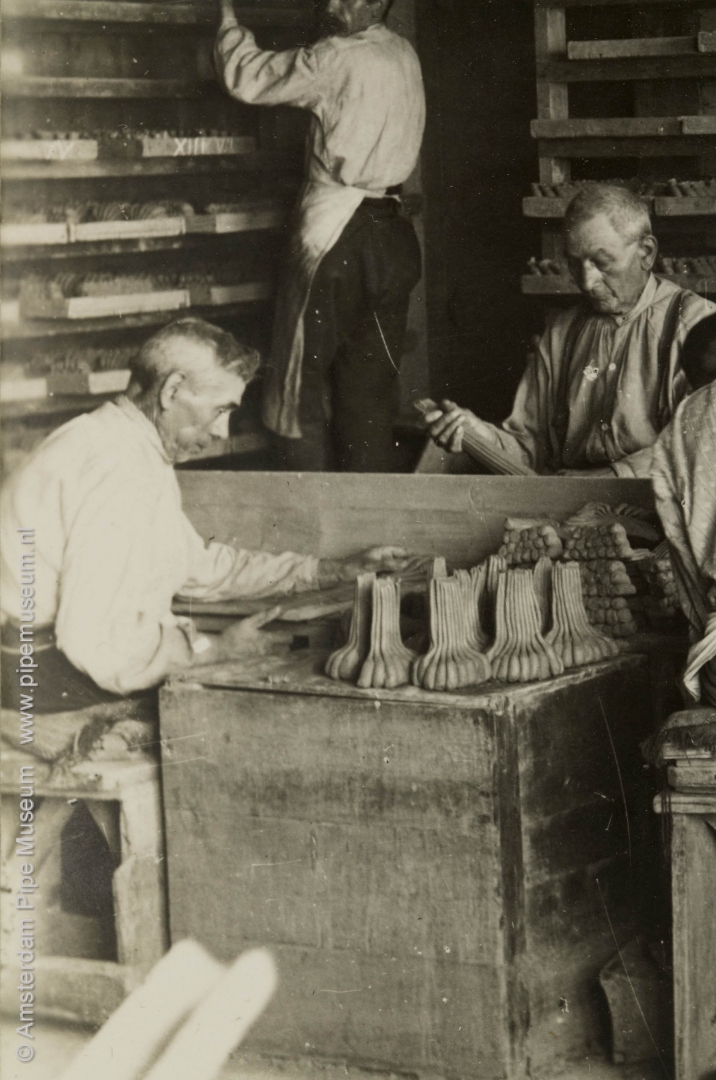

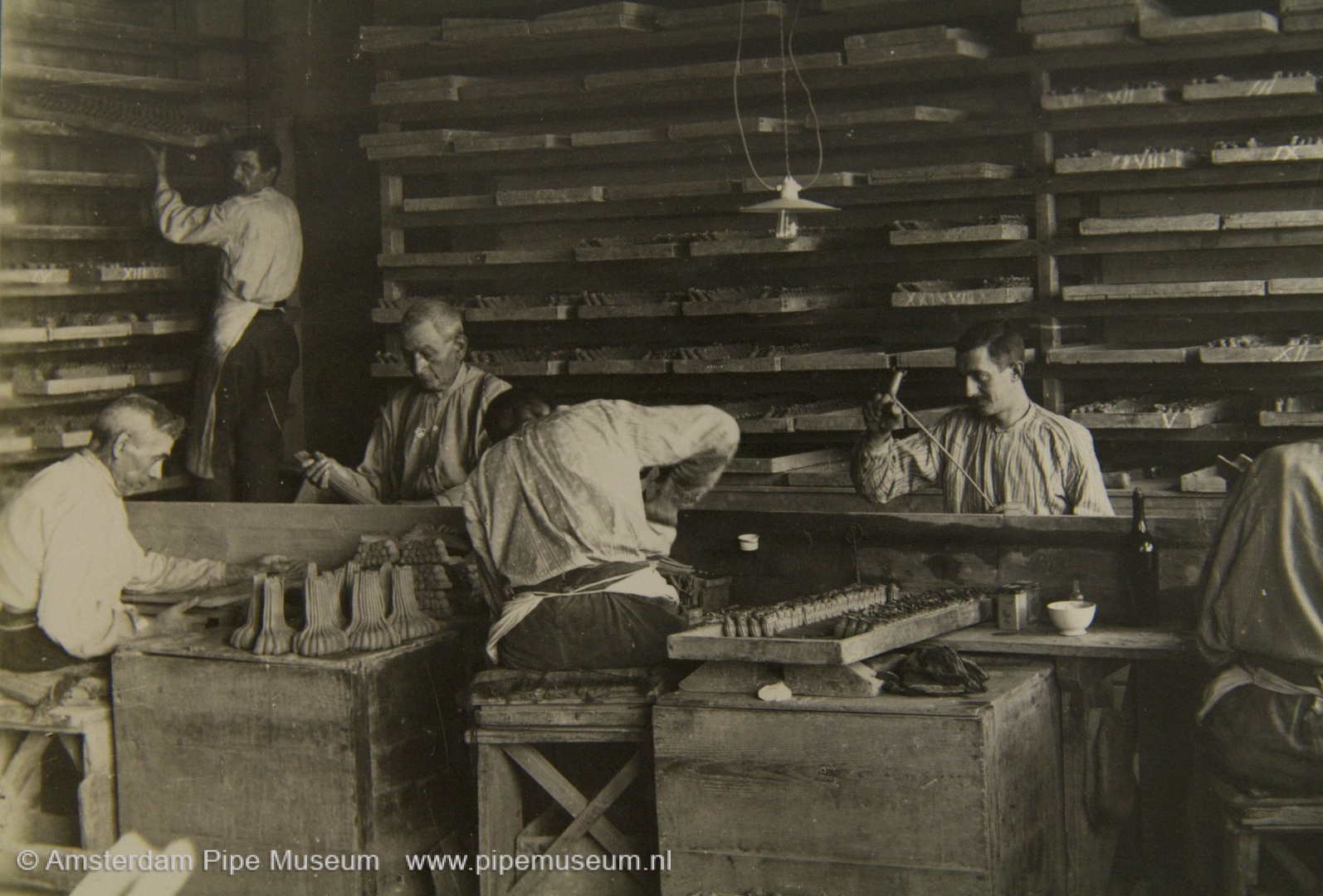

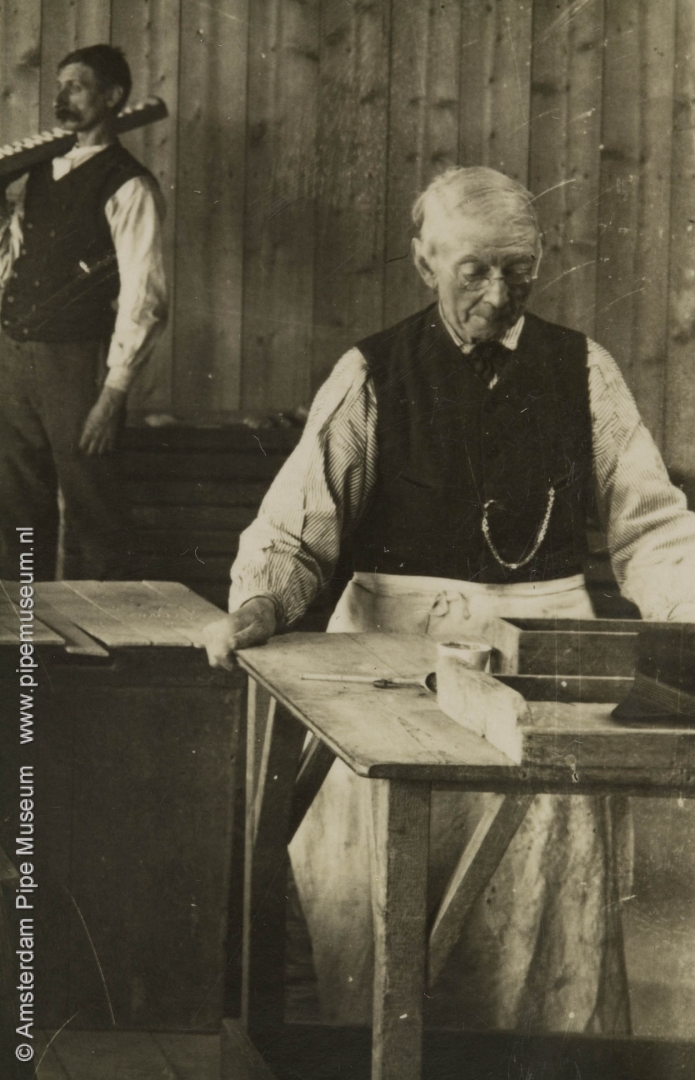

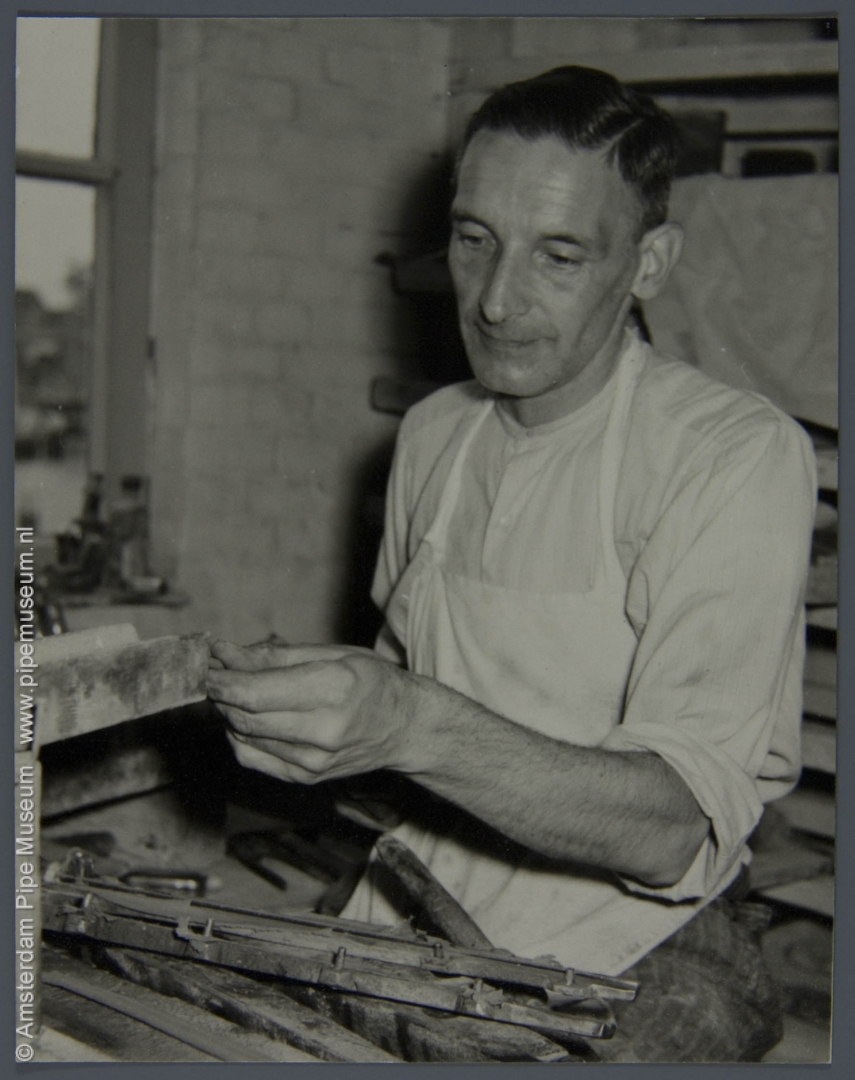

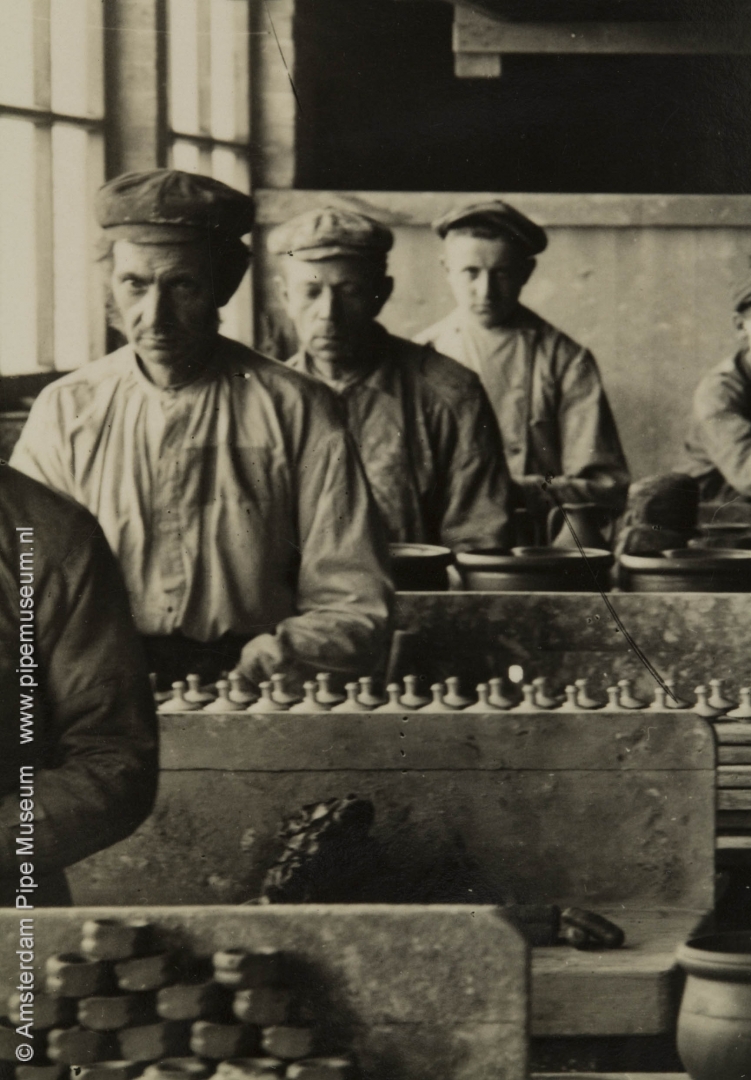

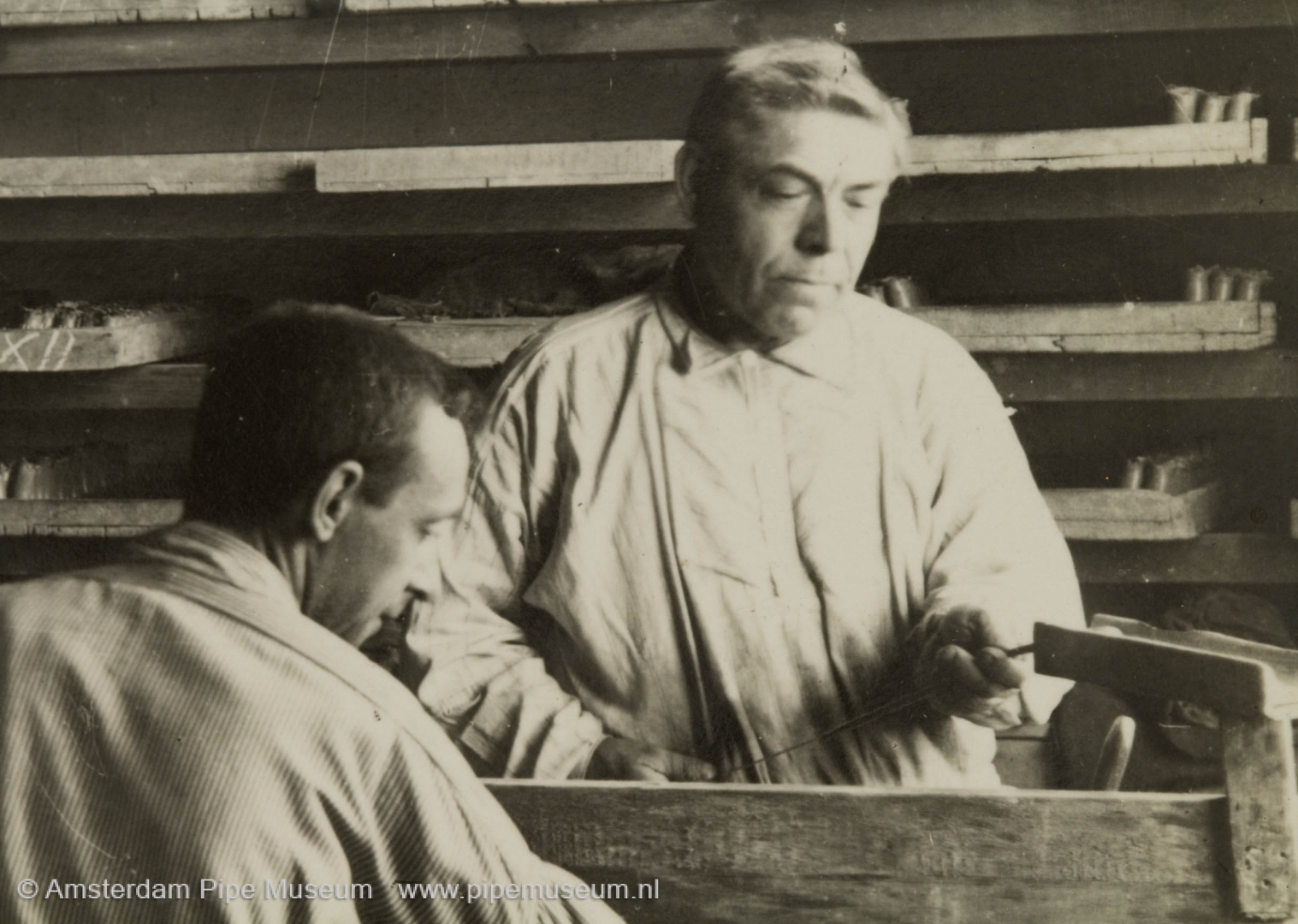

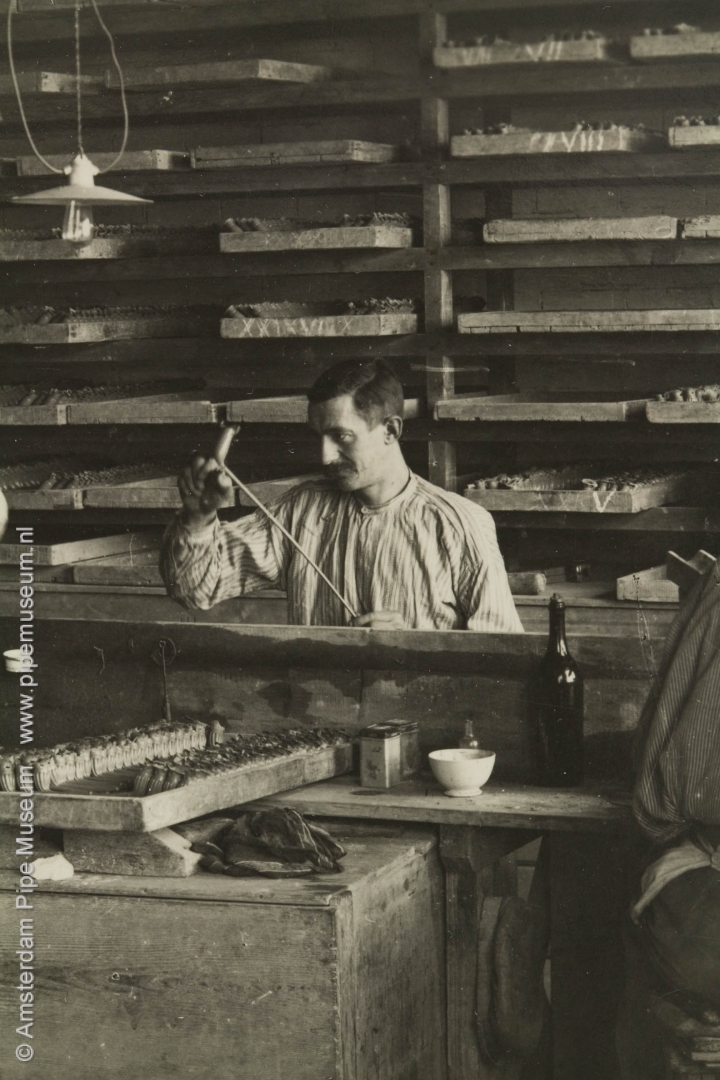

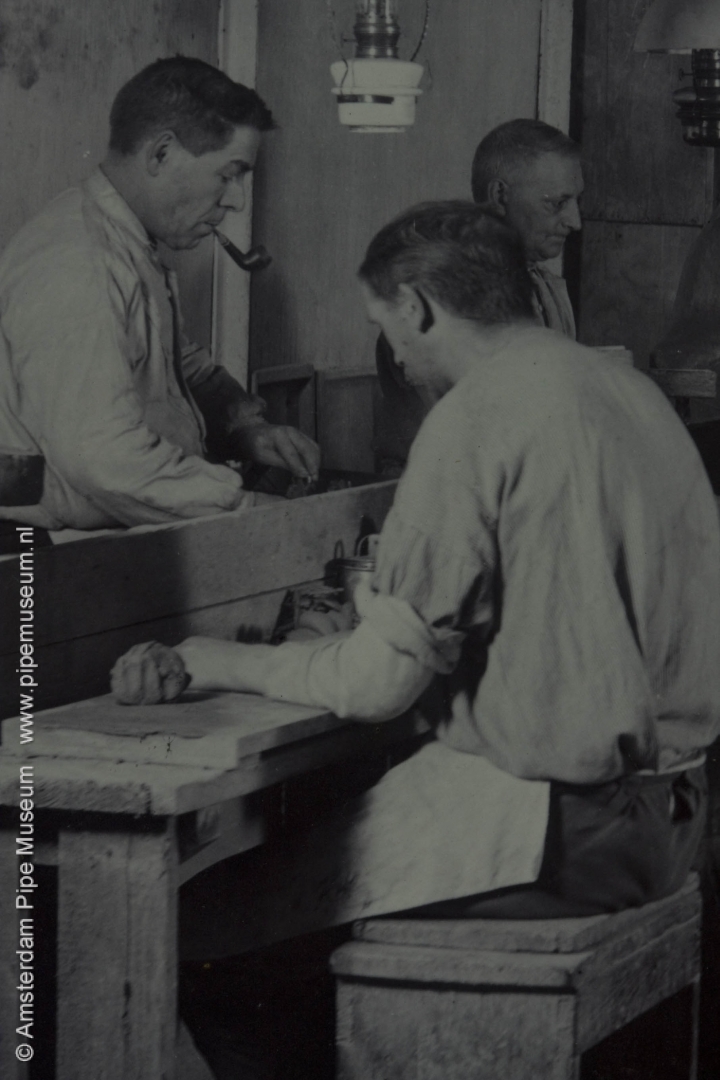

The pipe maker is referred to as kaster. He throws the clay roll on an iron wire, known in technical terms as weijer, and then places it in the press mold. After the two-part mold has been clamped in a vice, the pipe bowl is hollowed out with a stopper. This creates a smooth, tight pipe. With a knife, the molder now cuts away the sheets from the mold seams and then the clay pipe is dried.

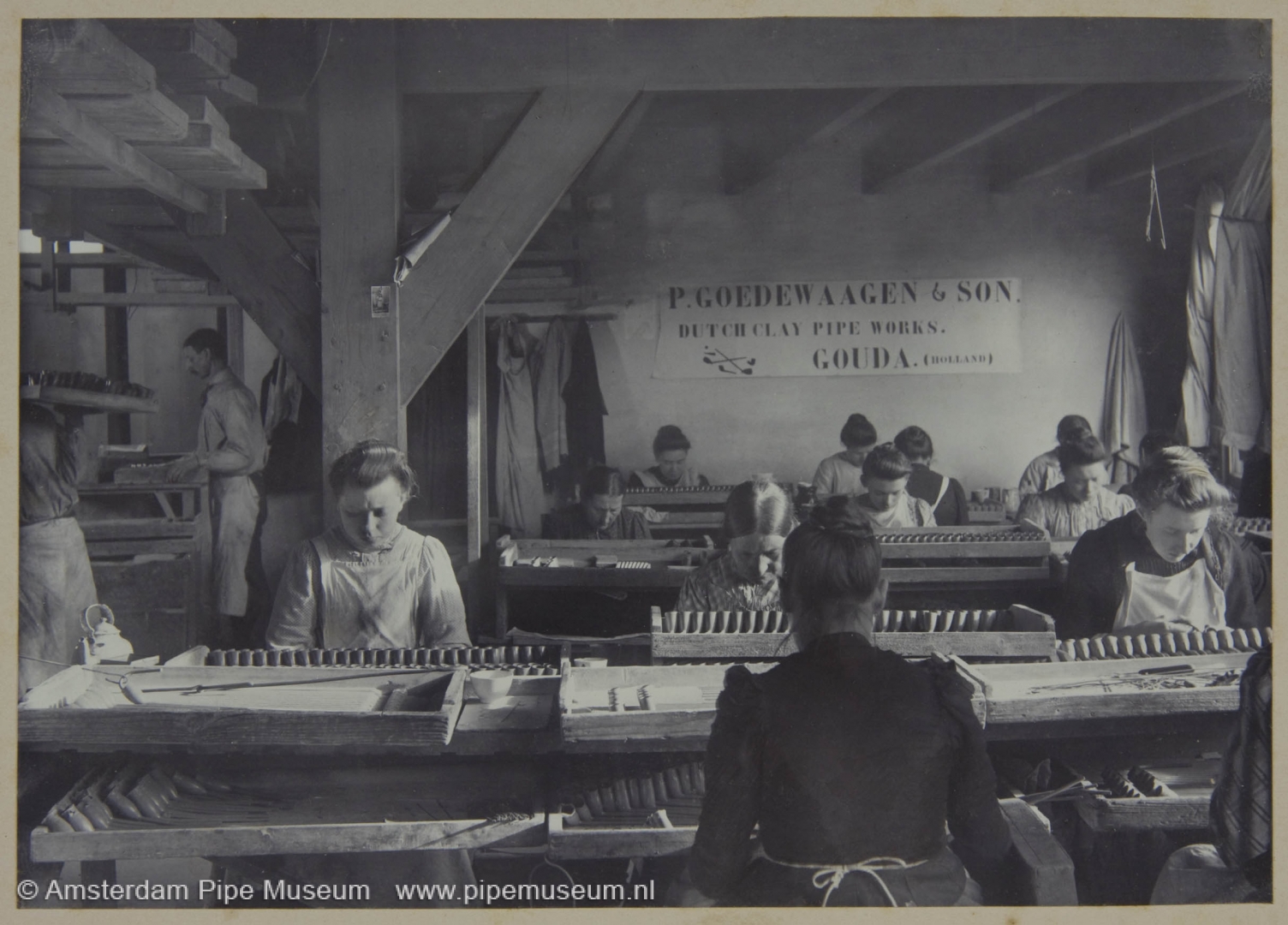

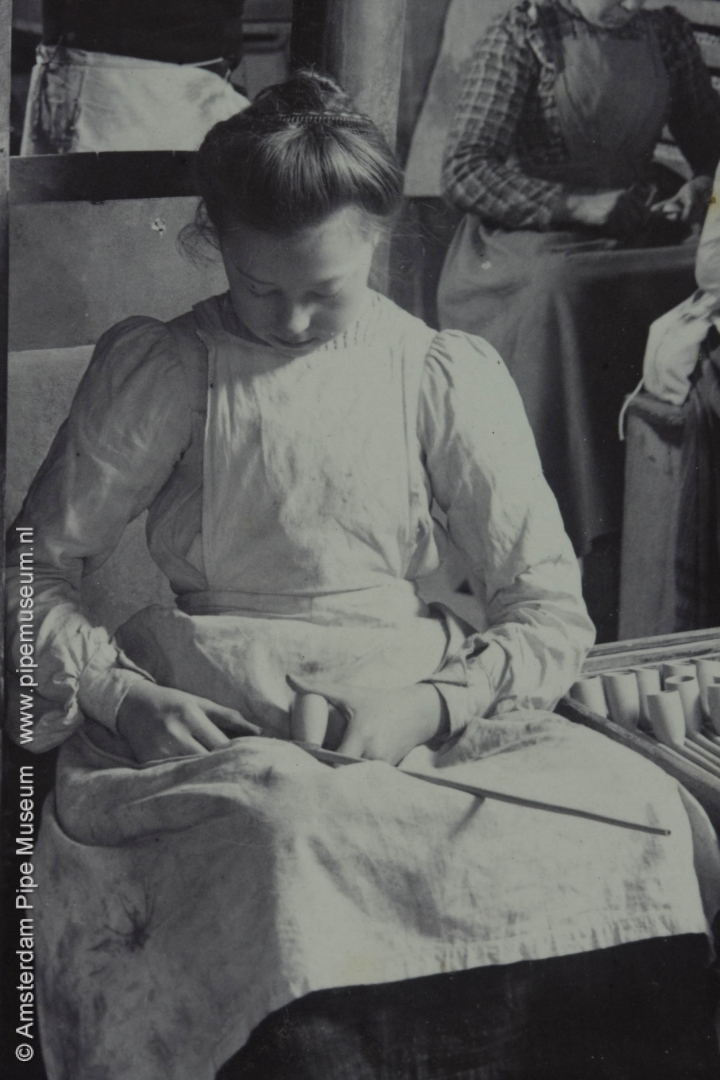

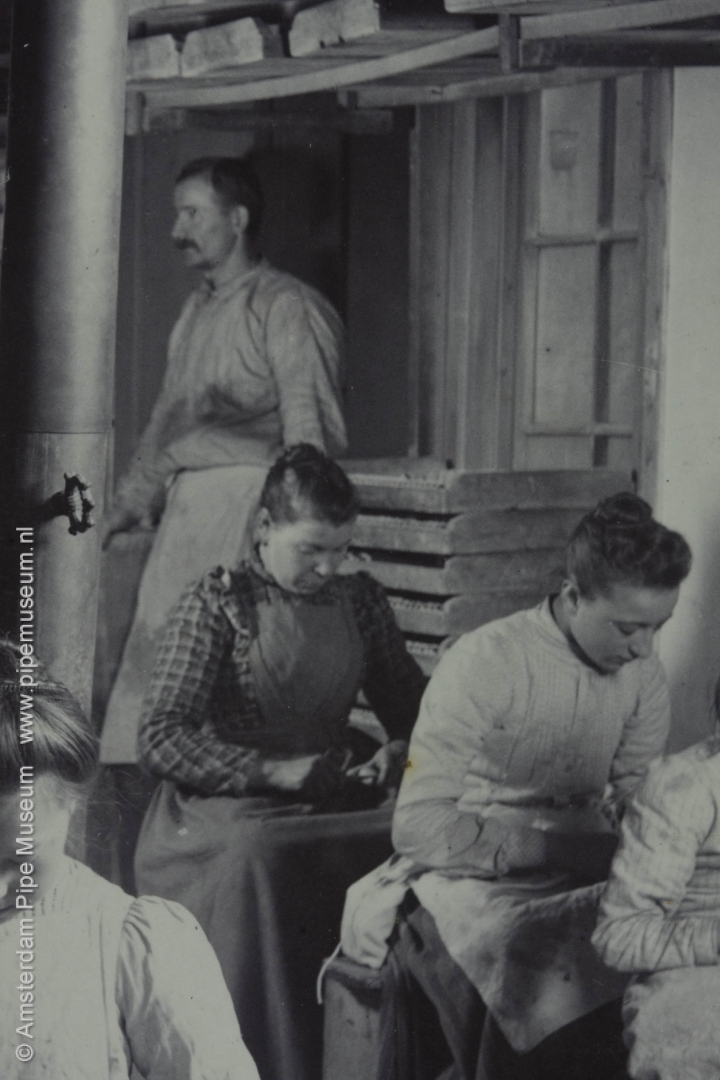

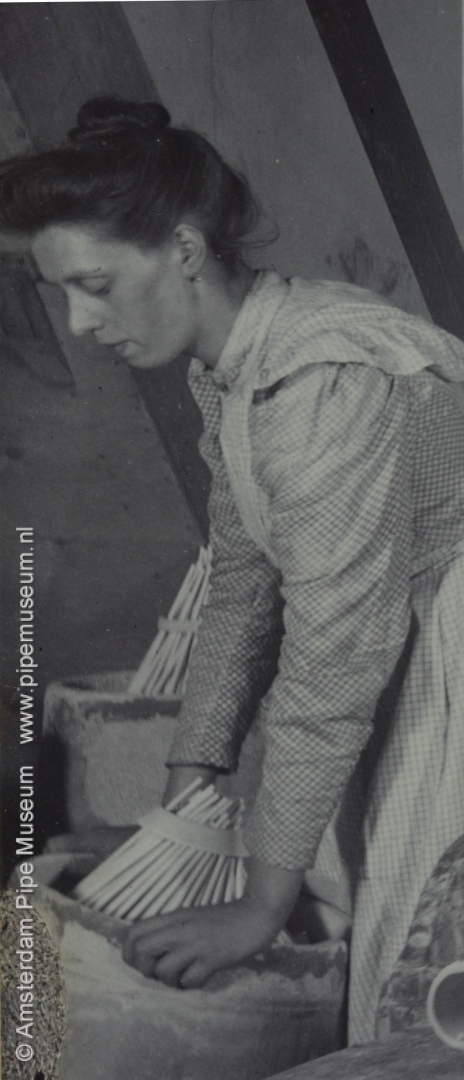

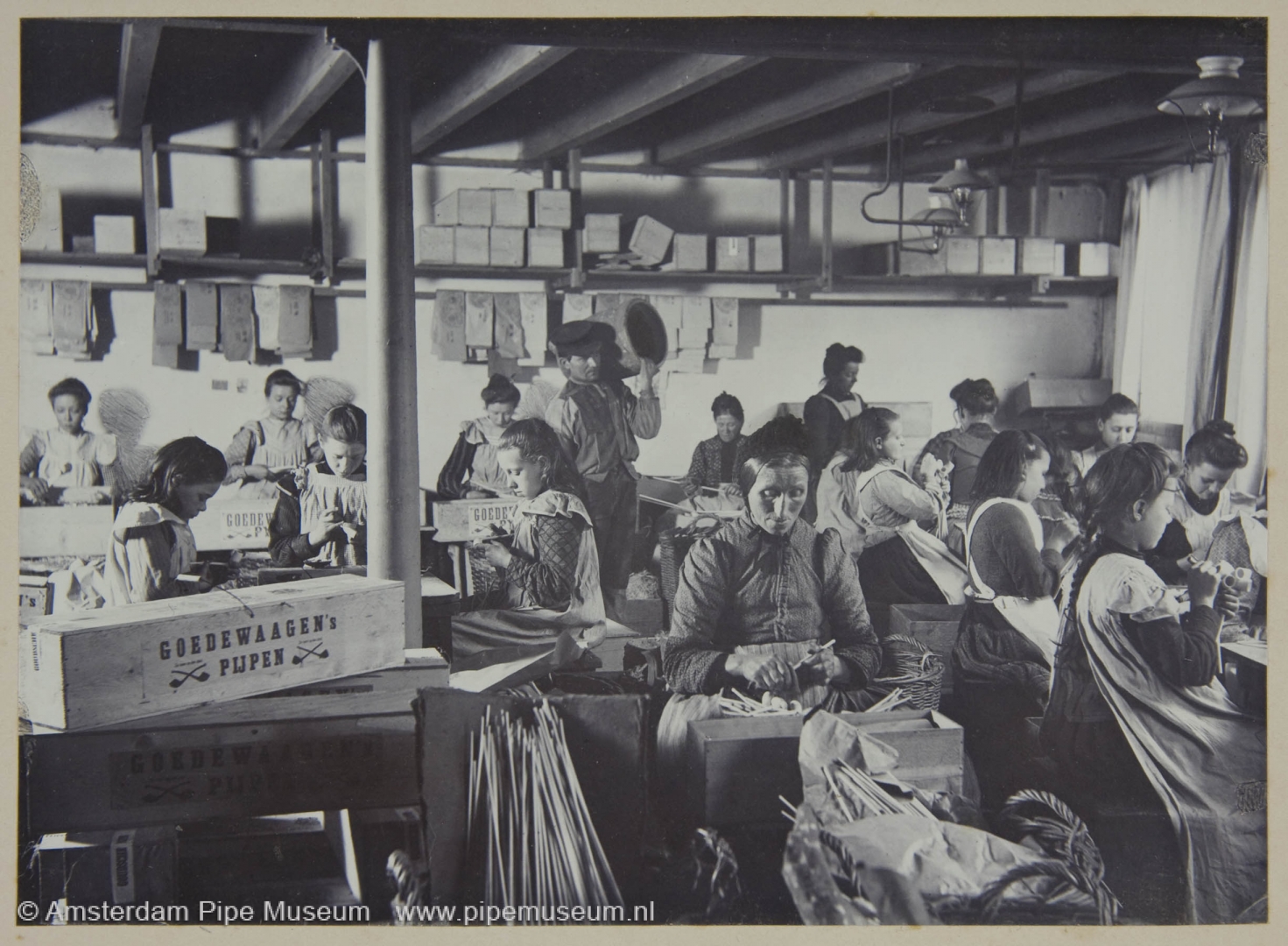

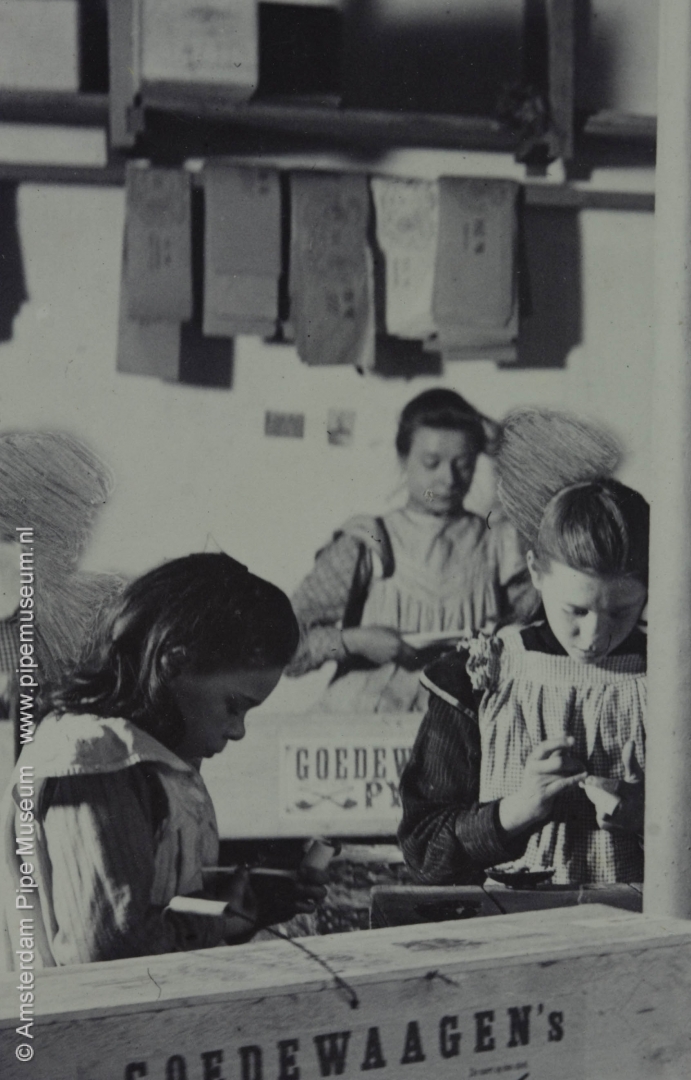

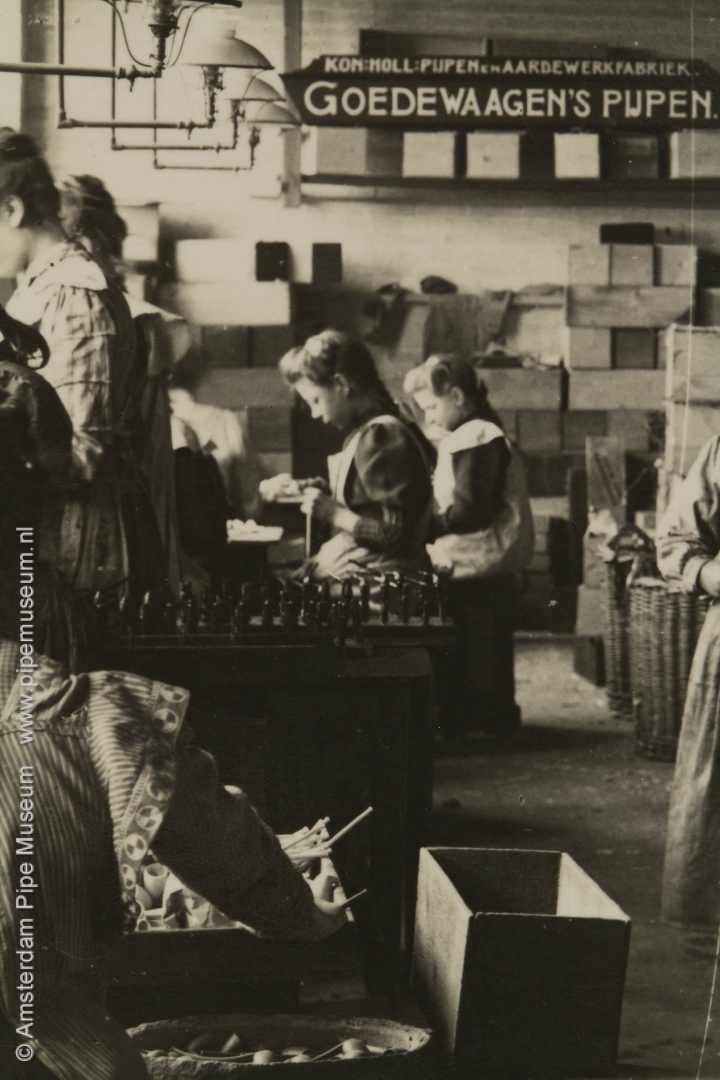

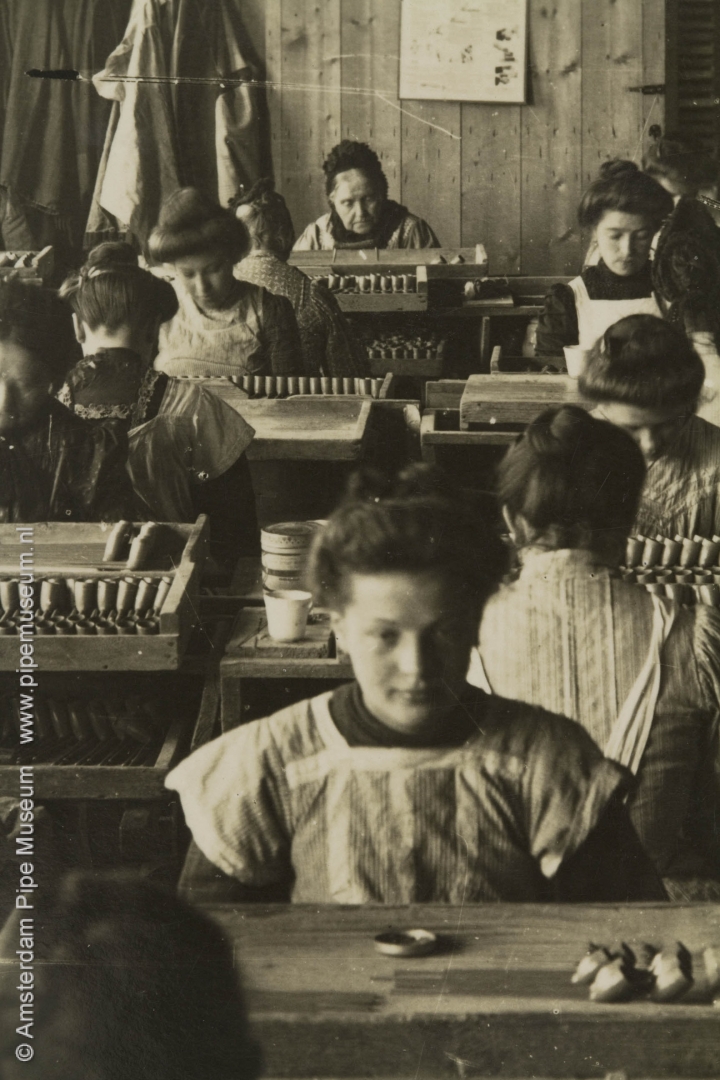

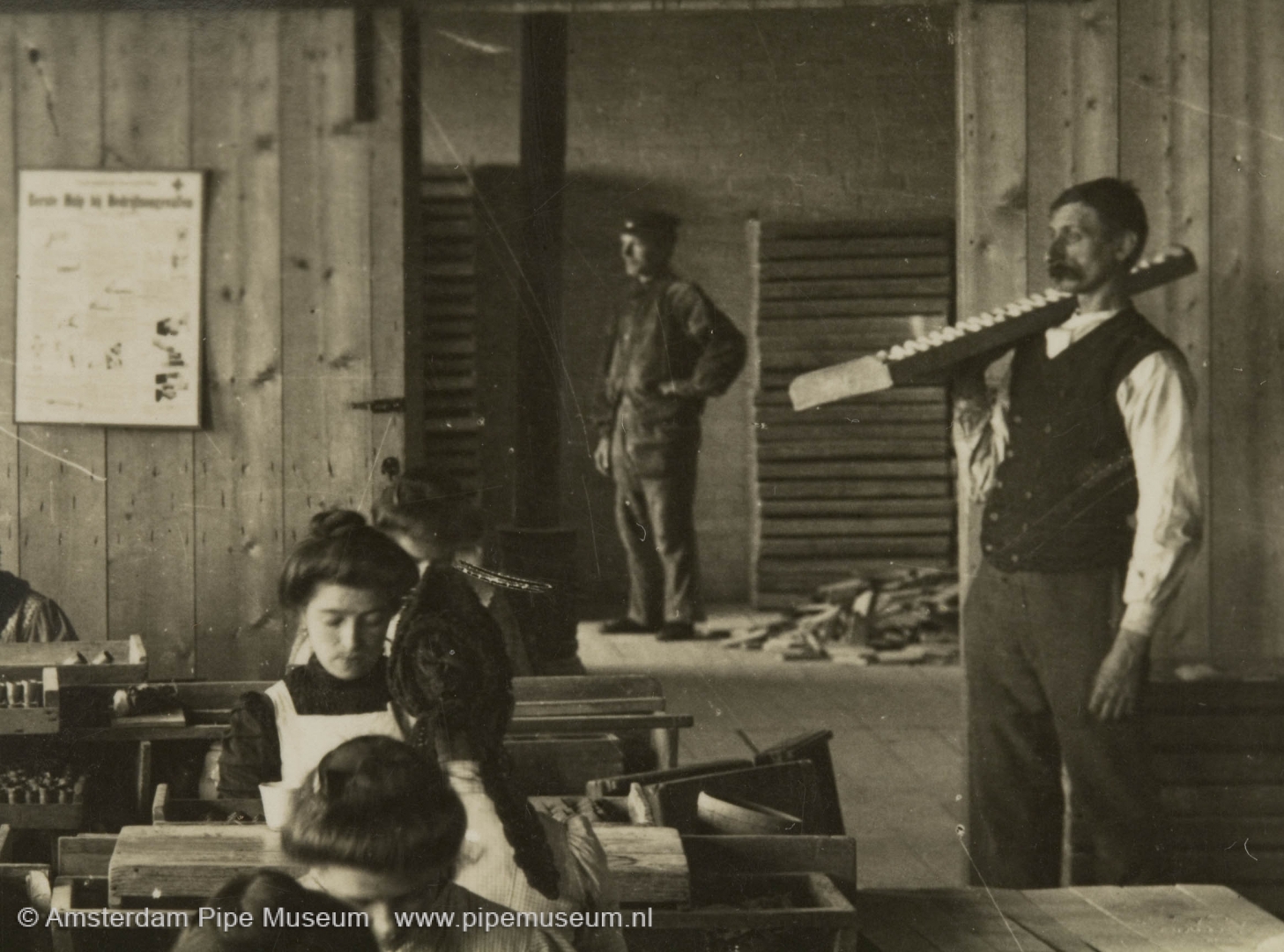

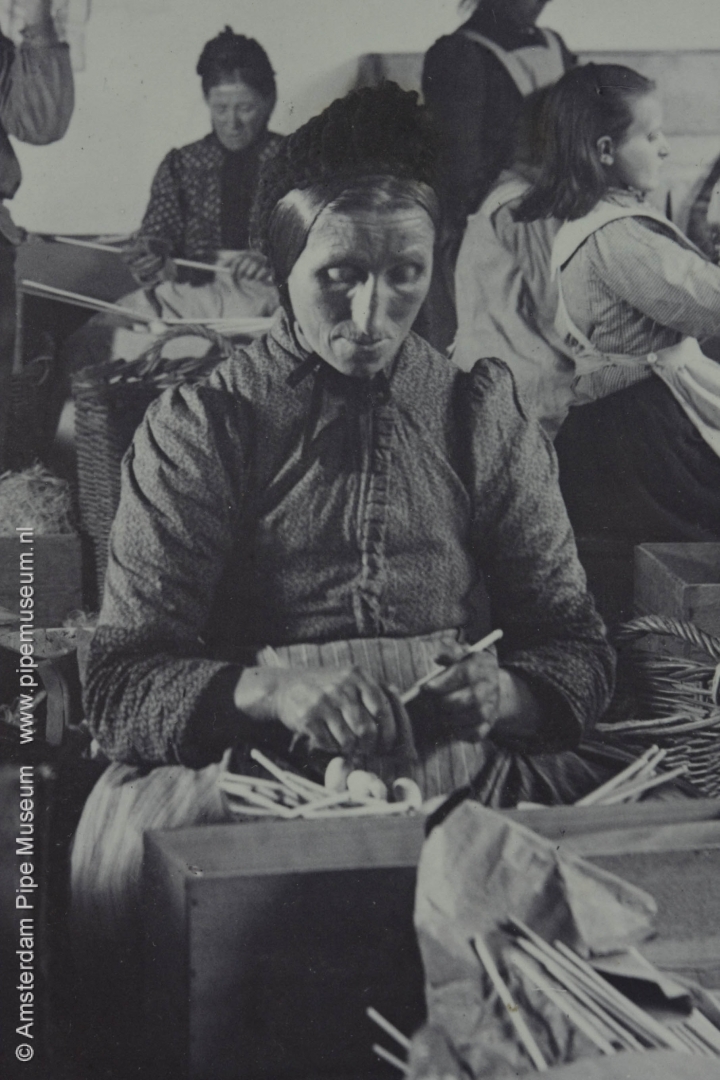

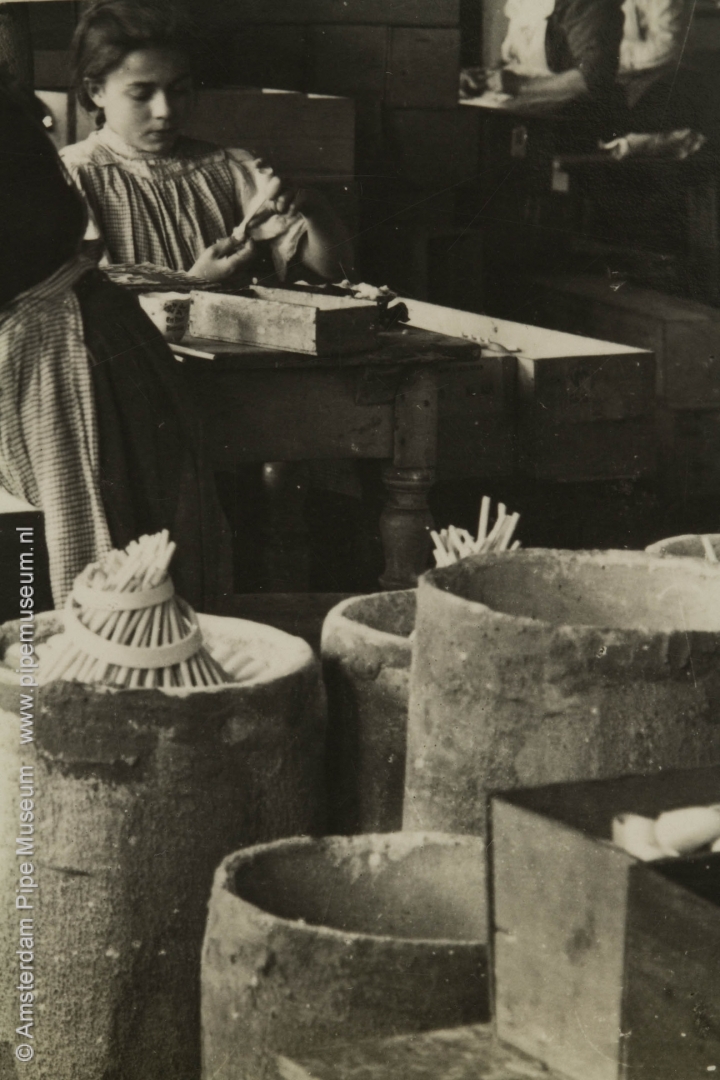

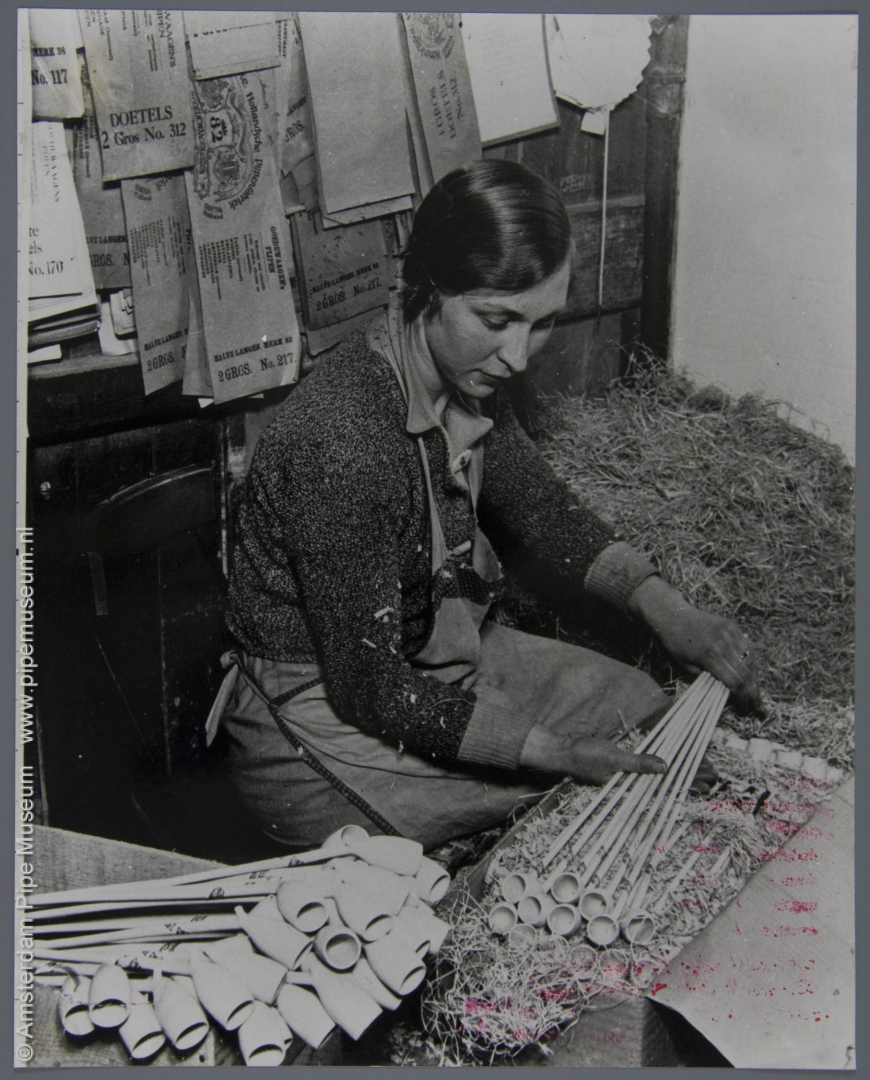

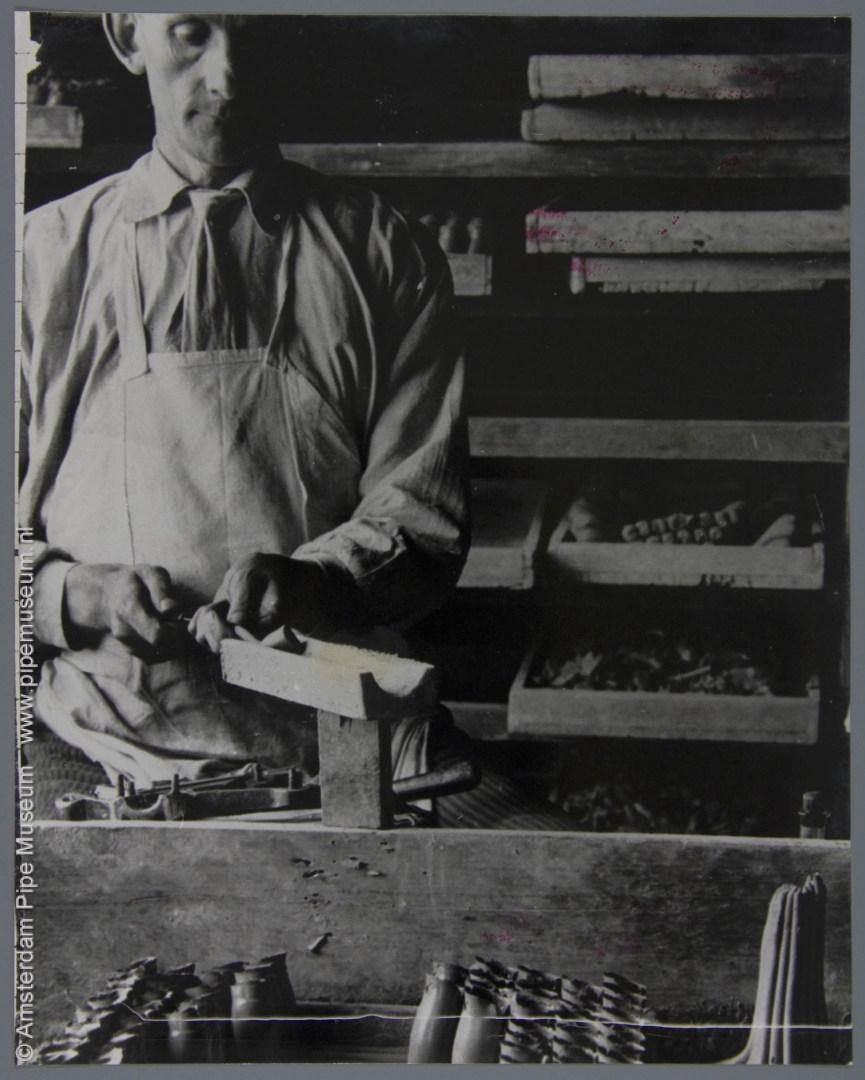

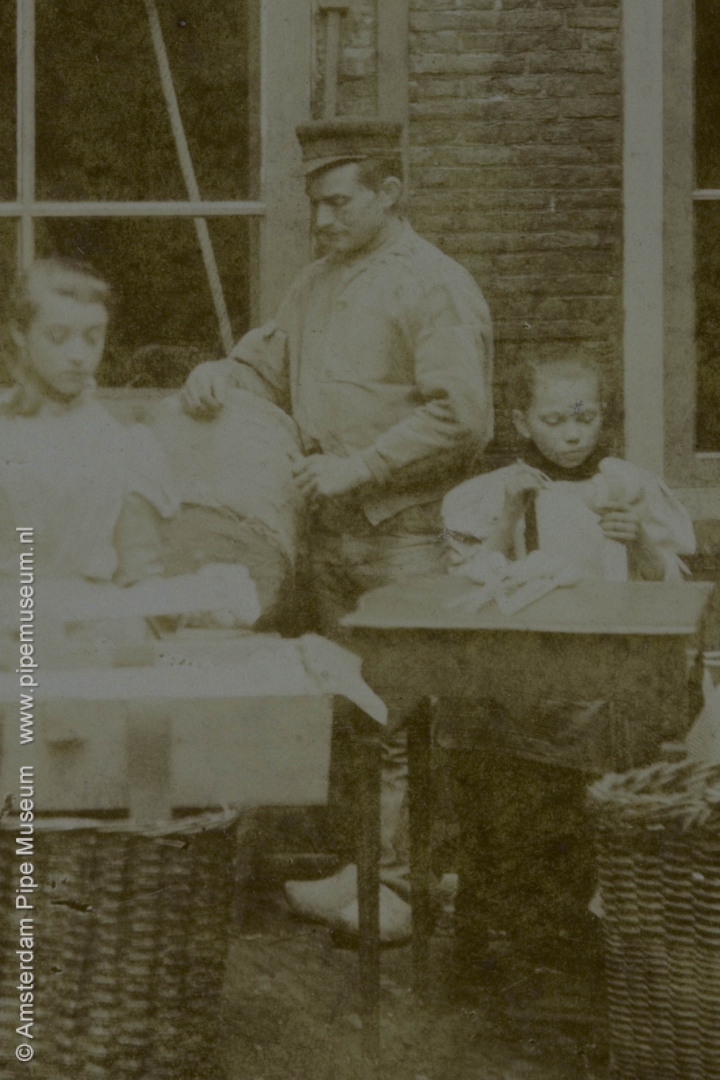

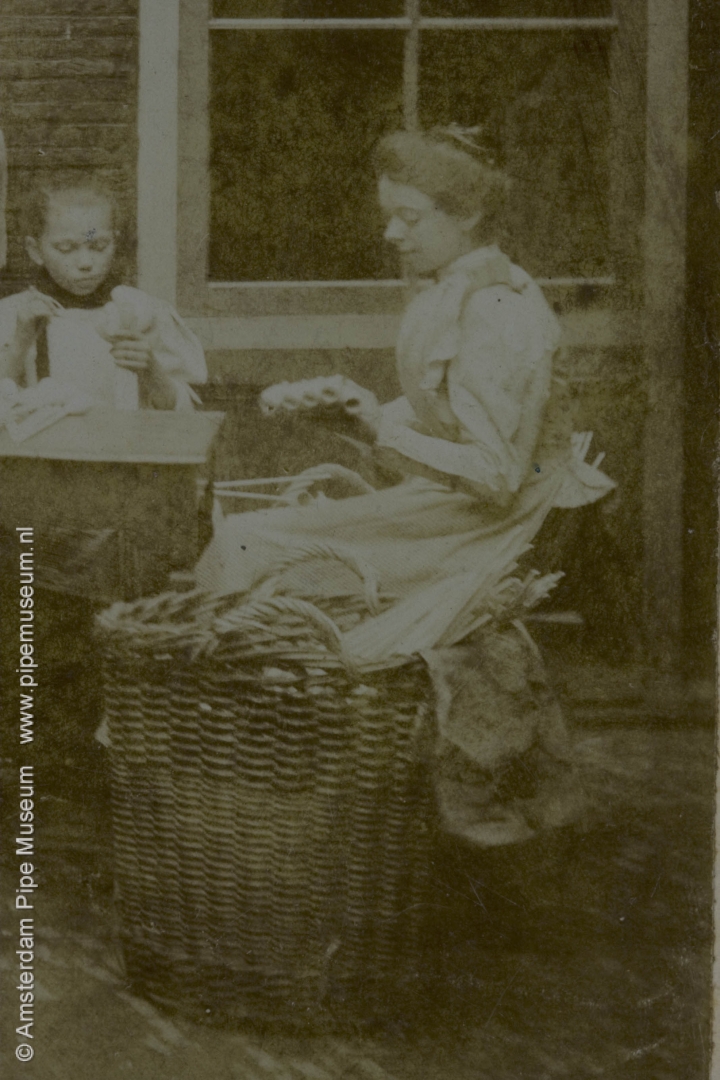

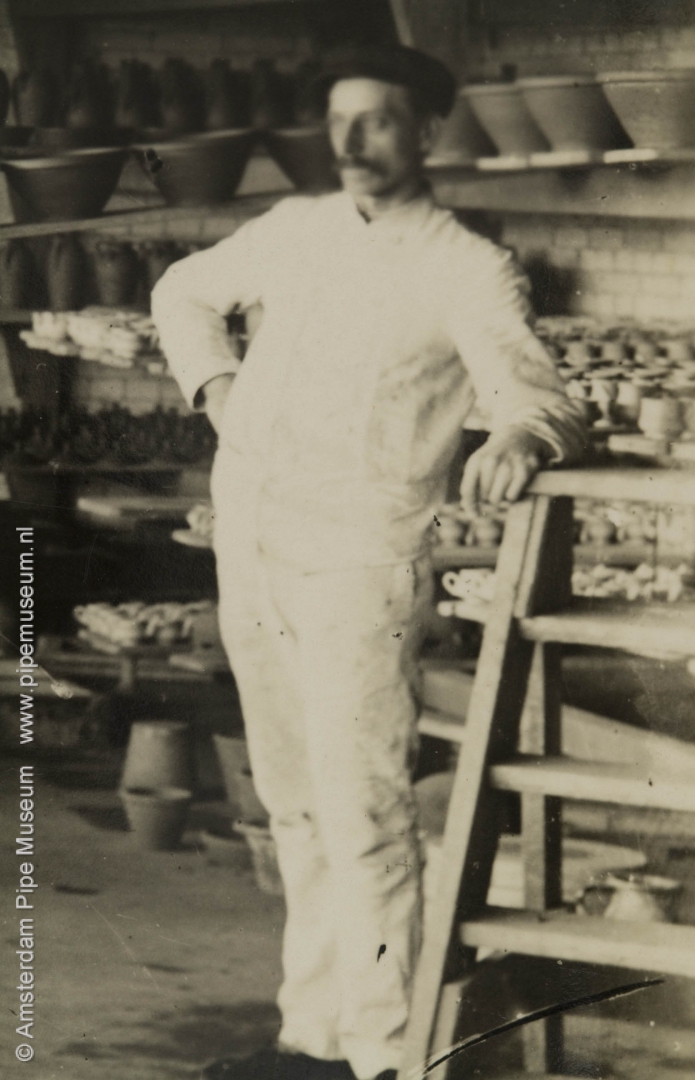

In a leather-dry condition, the pipes are further finished. This is done by women, called tremsters. They shape the pipe by smoothing the mold seams, rounding off the bowl opening nicely and stamping the maker's mark. In their lap are the three tools for this. The best kind of pipes are stroke burnished: the leather-dry clay is polished with agate stone. The women who do this work are called glaasters.

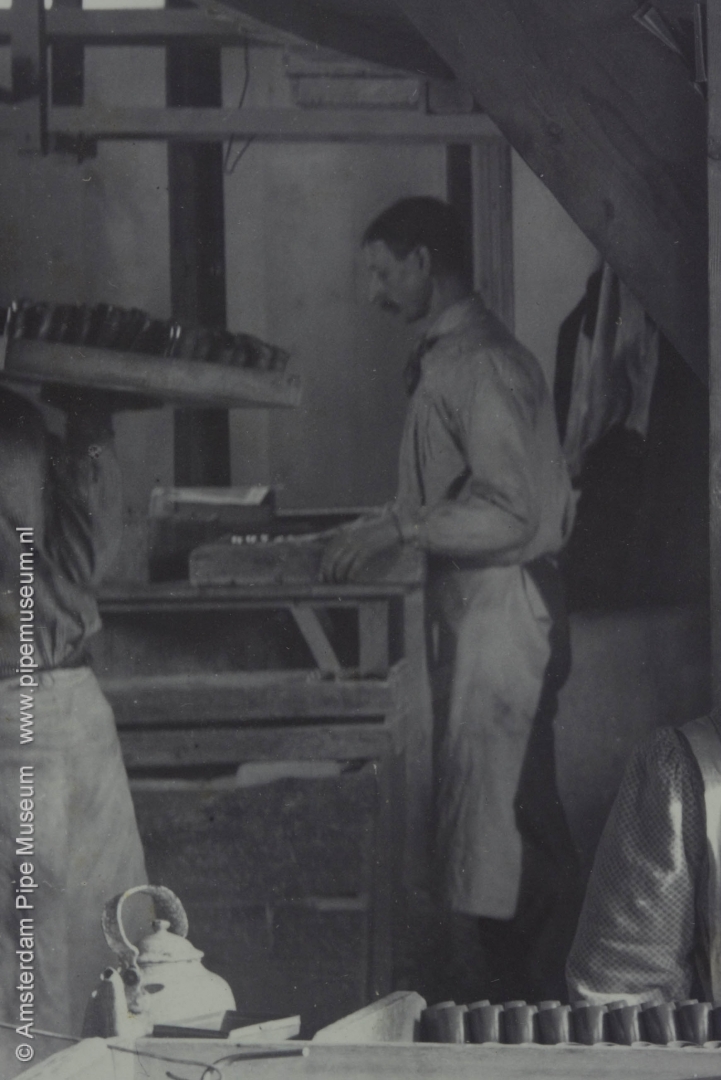

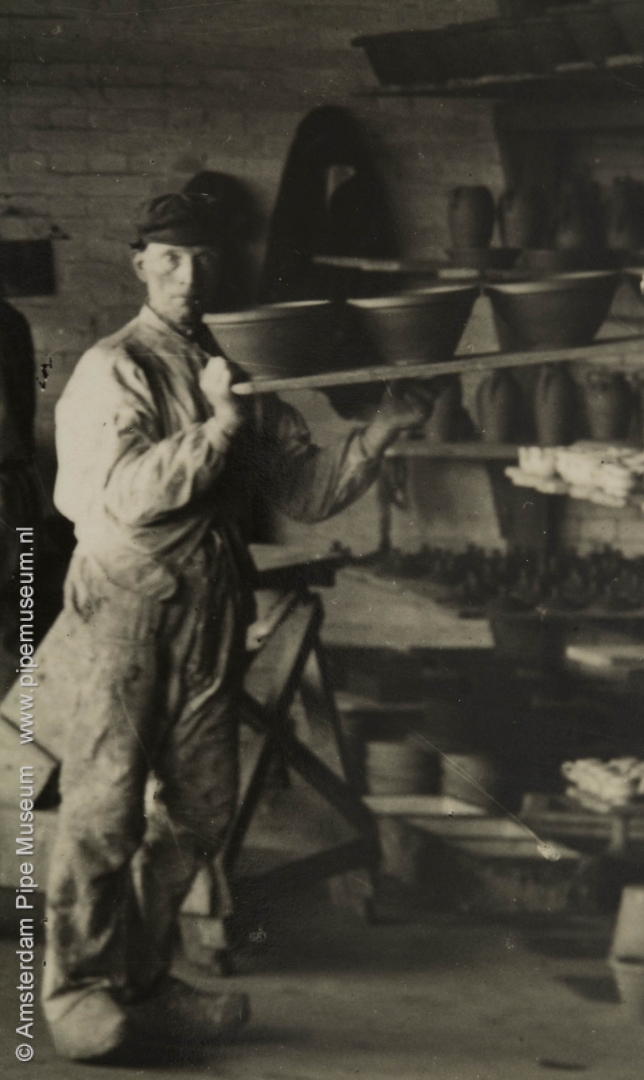

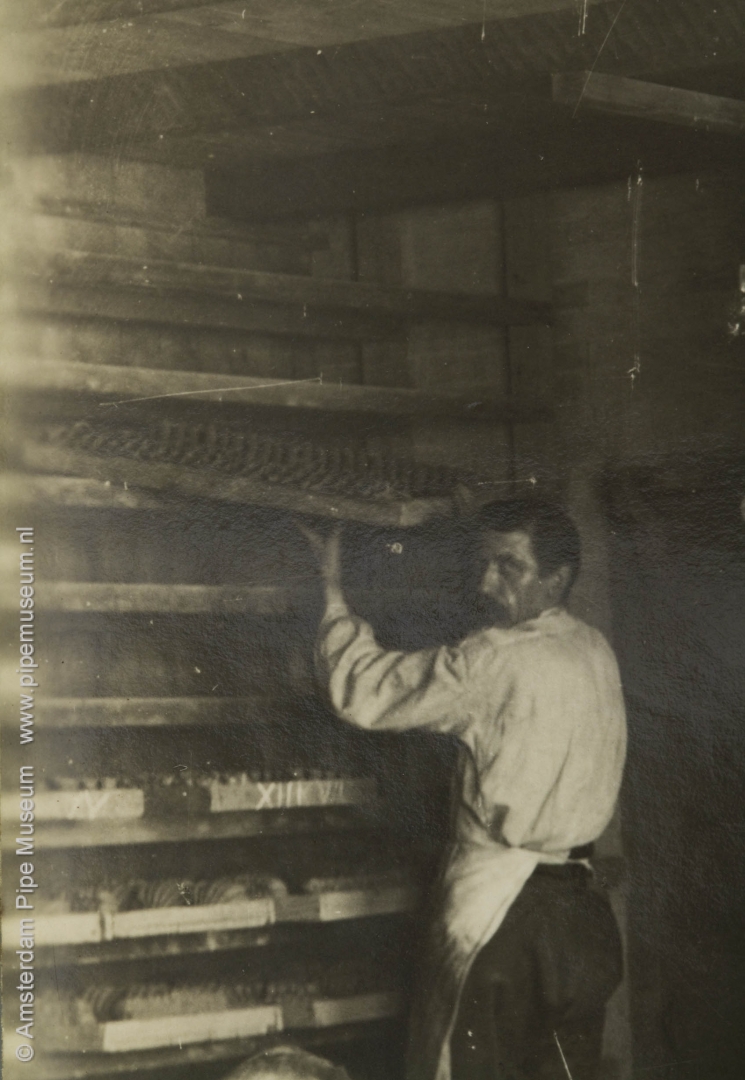

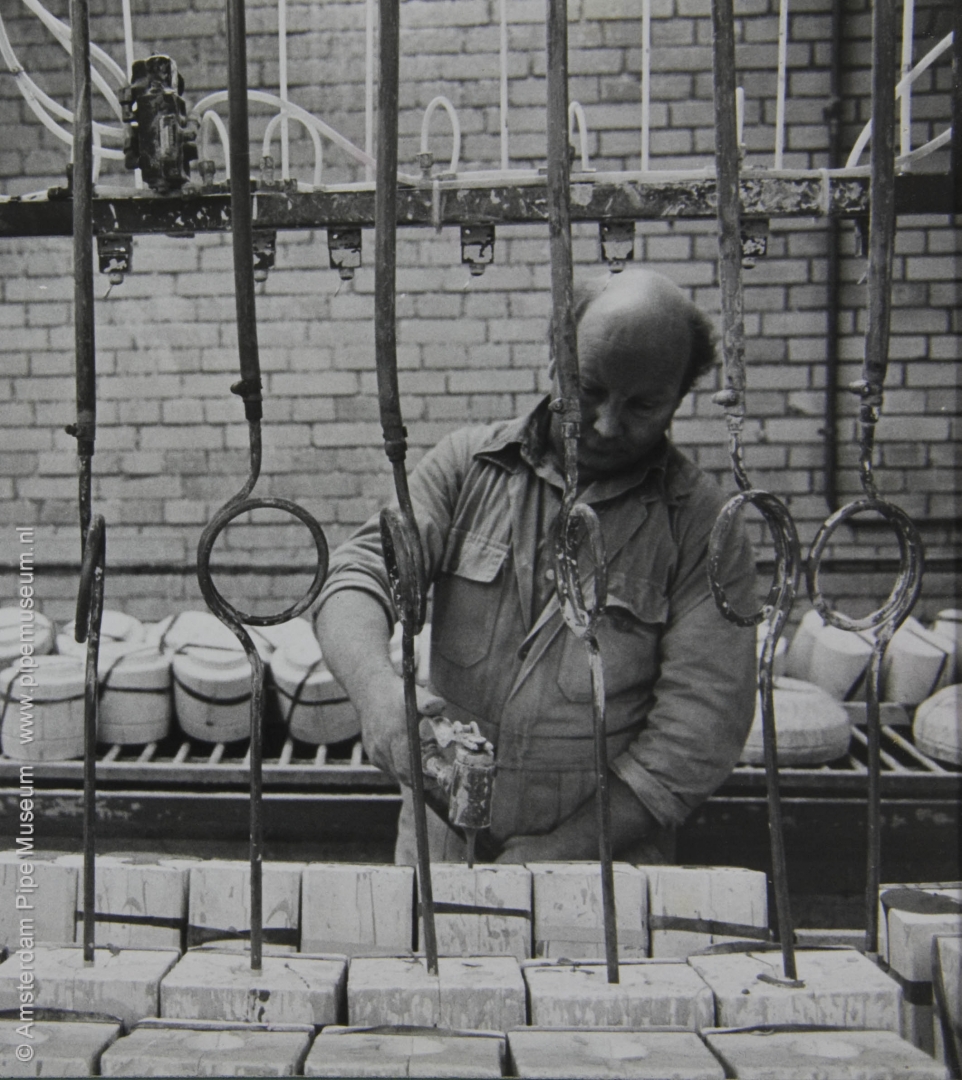

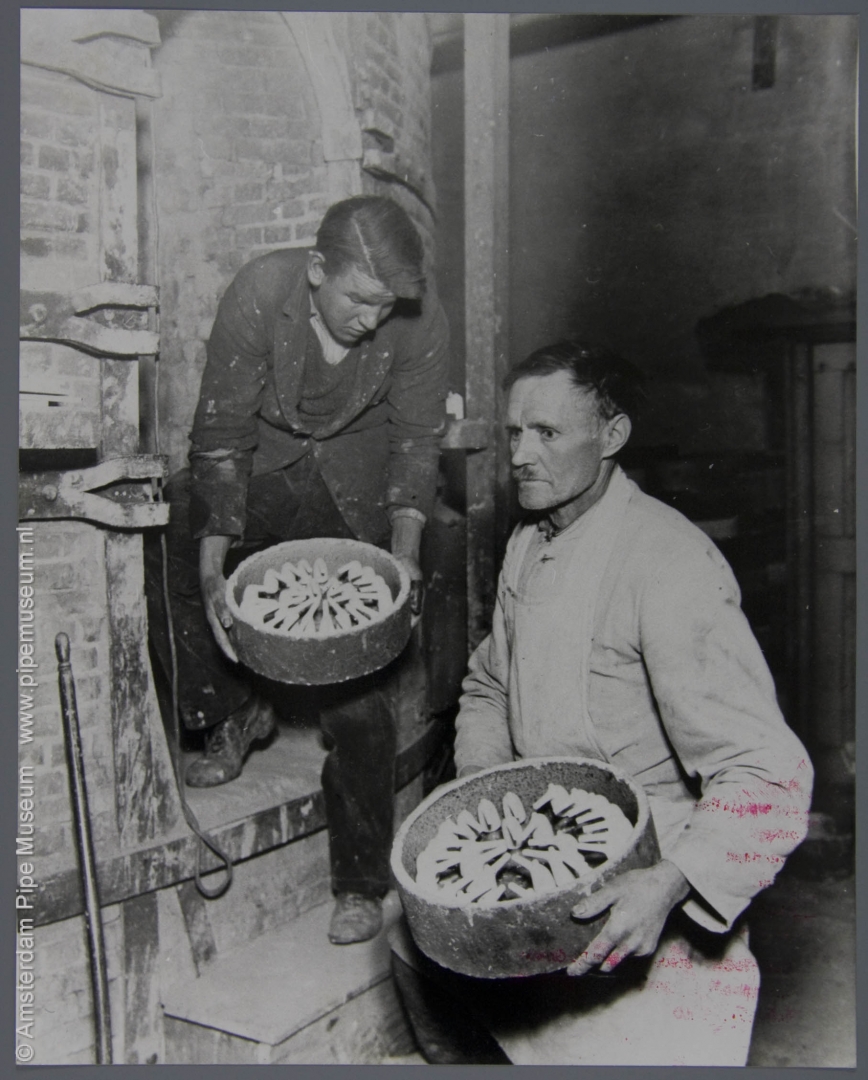

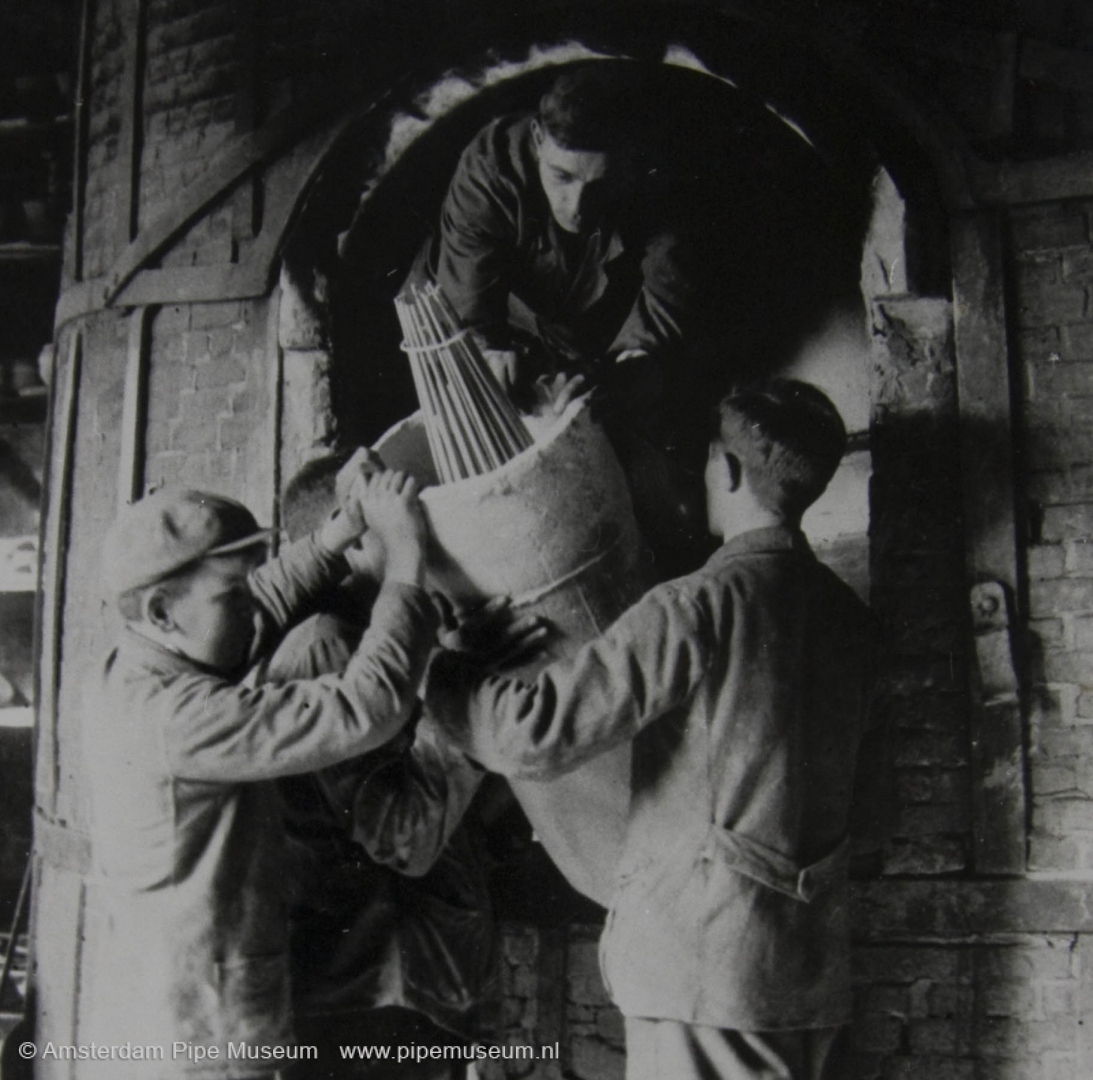

Now the pipe is ready to be baked. This is outsourced to the potter who fires the potter's kiln. To ensure the white color of the pipes, they are packed in an earthenware pipe pot or saggar. Otherwise, smoke and flying ash would discolor the white pipes. The firing process takes about 24 hours.

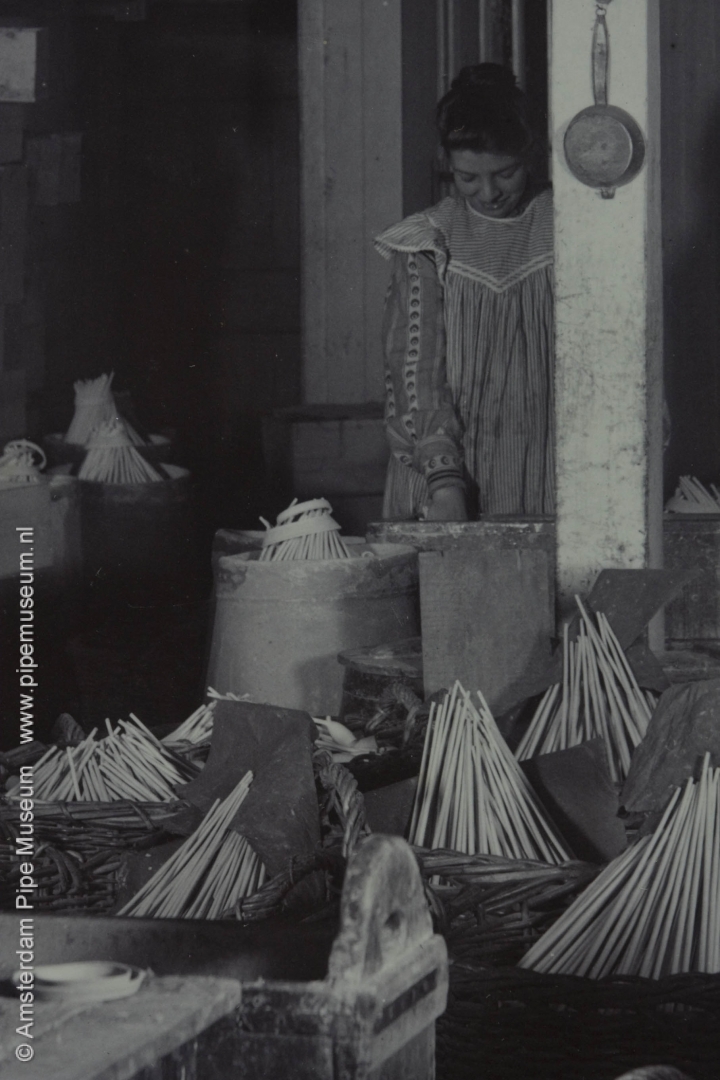

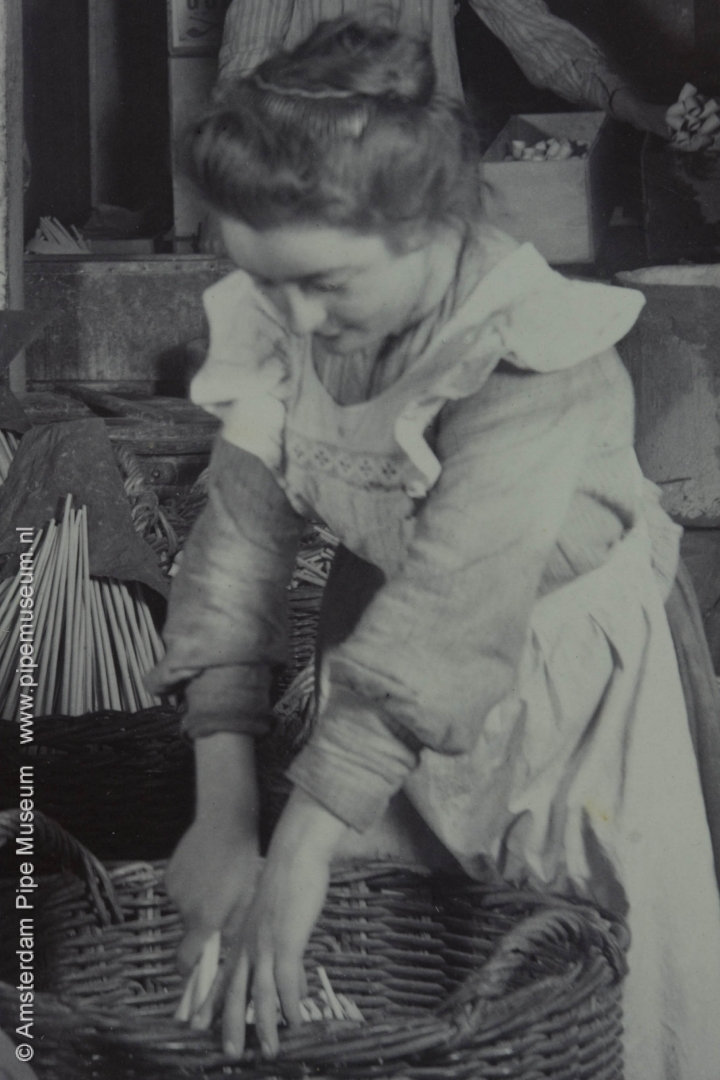

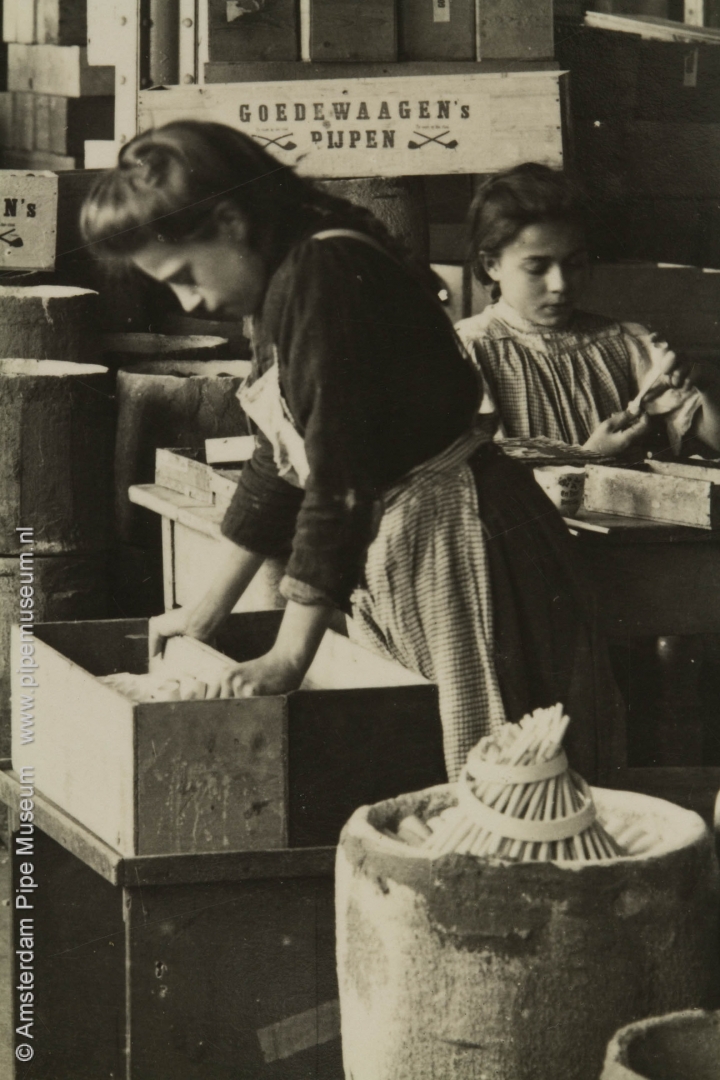

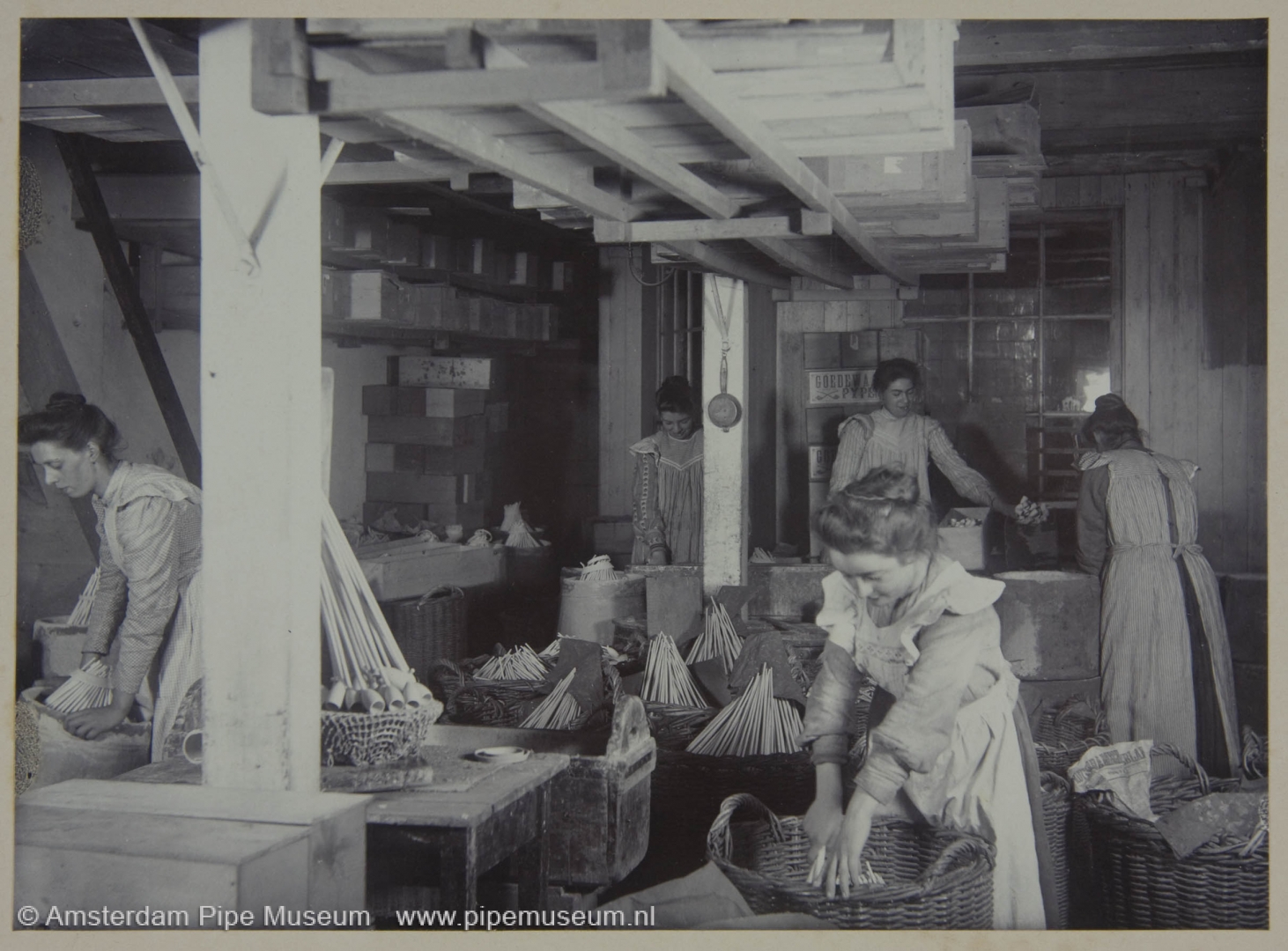

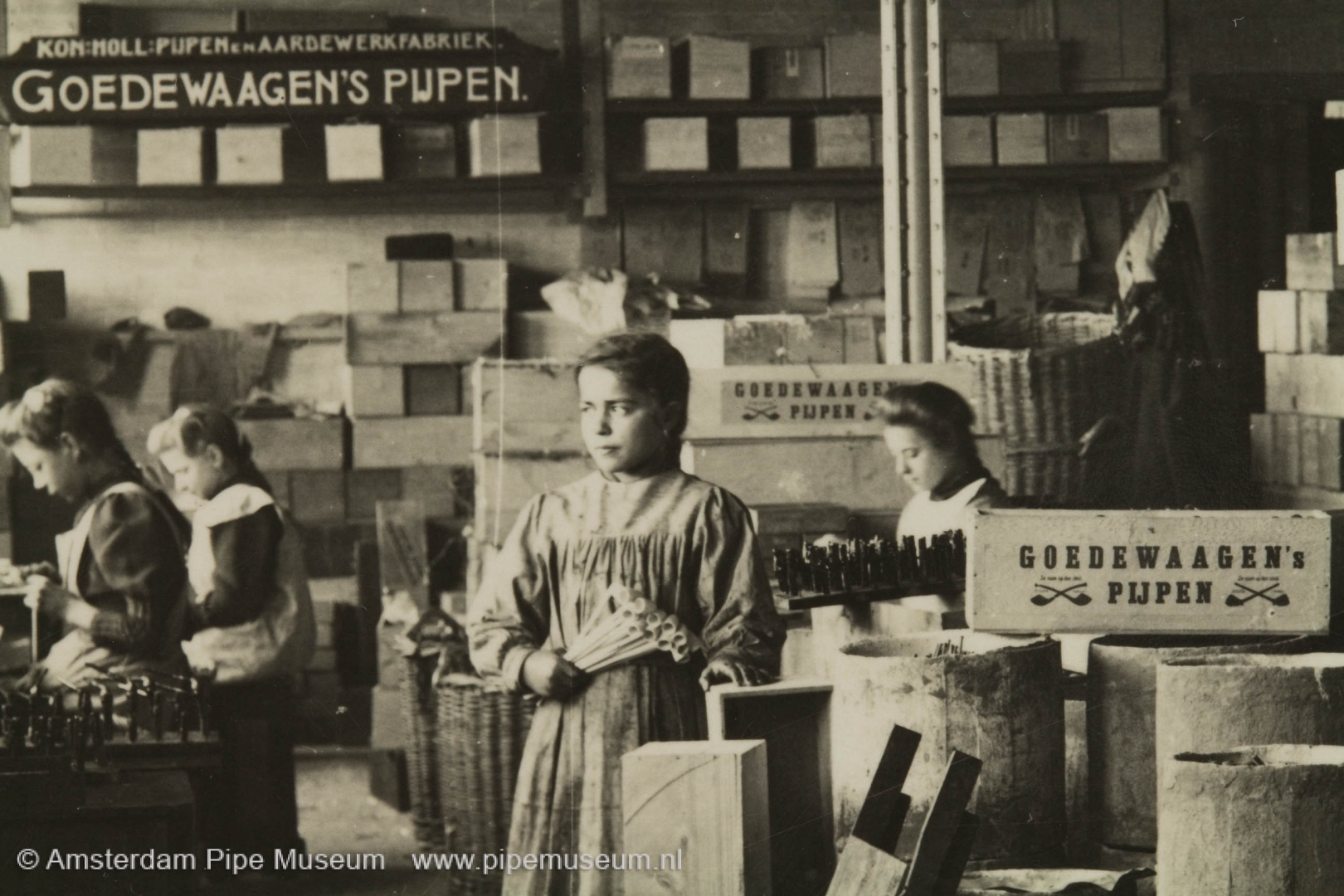

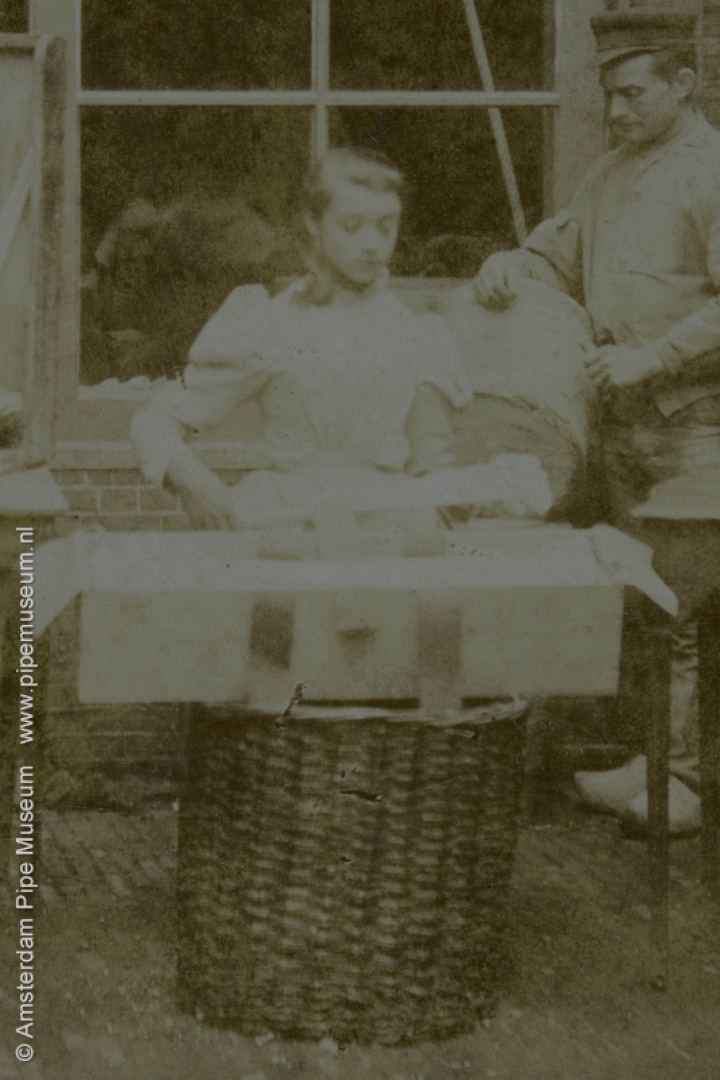

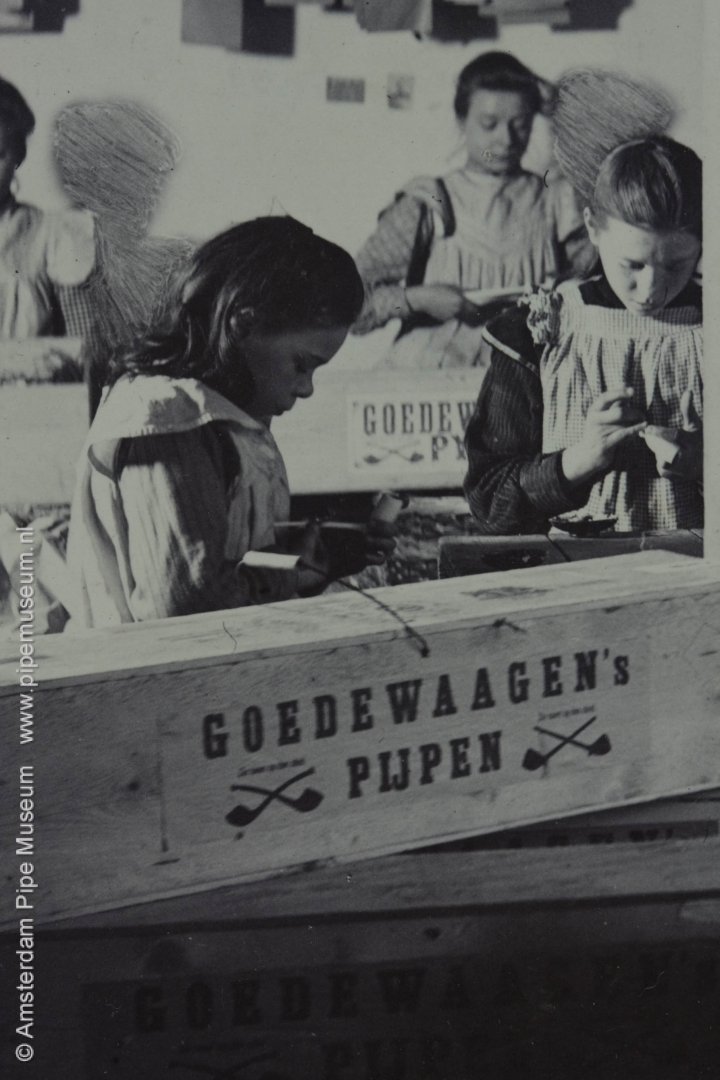

After firing, the pipes are sorted by quality. The best varieties are dipped in a solution of wax and soapy water and rubbed with a cloth. They are then packed in baskets or boxes. These packaging are provided with a rectangular piece of paper on which the manufacturer advertises his mark.