Pipemaker's tools

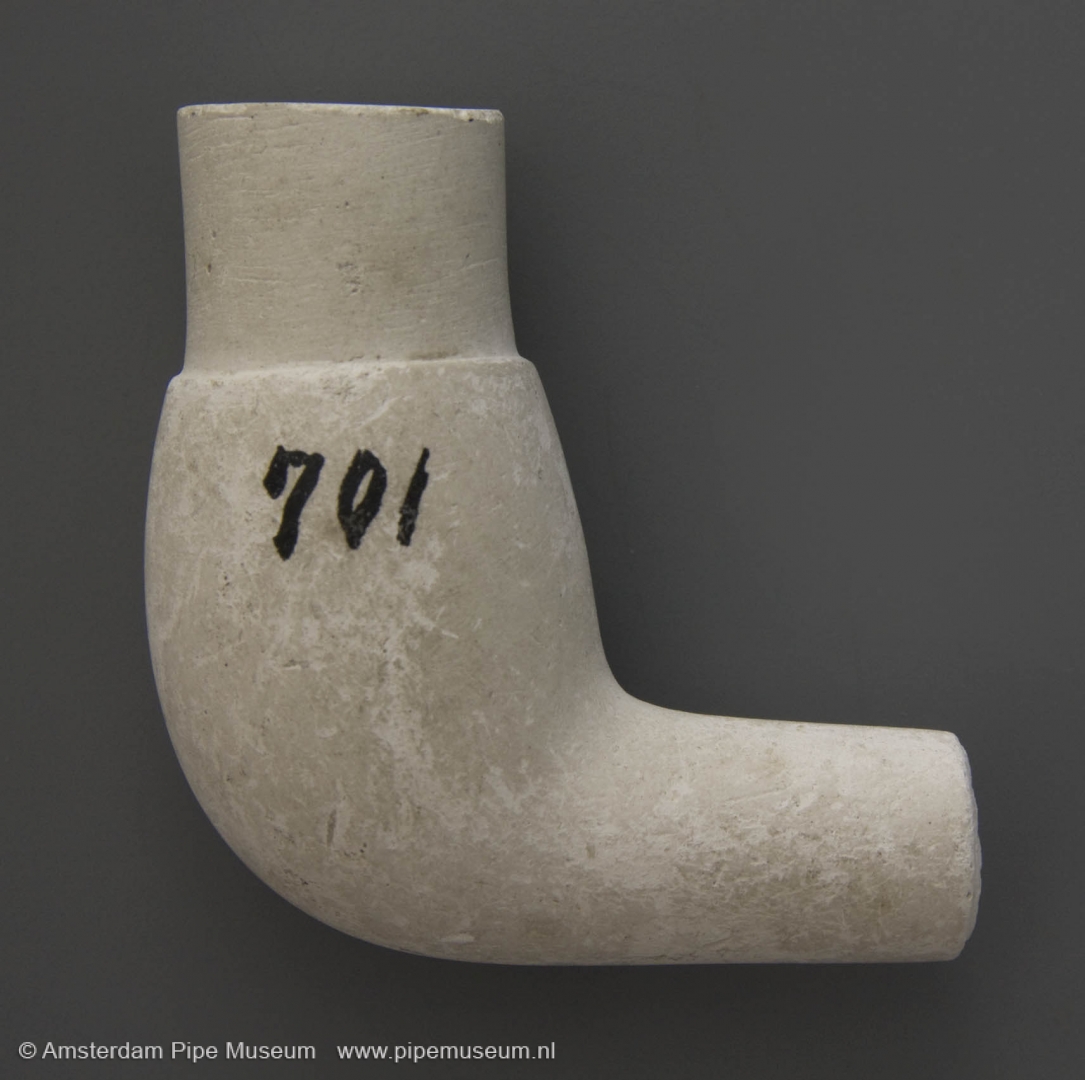

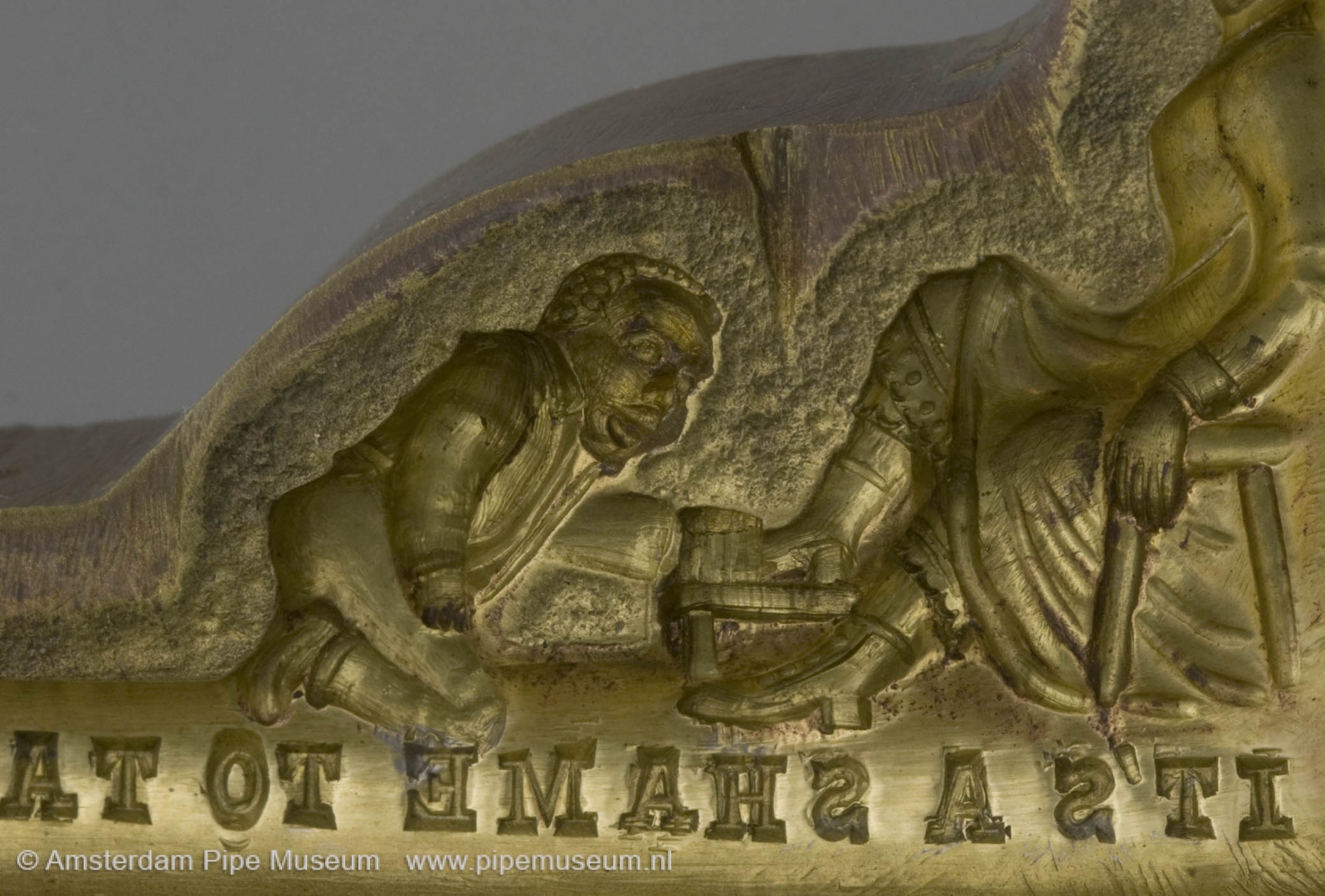

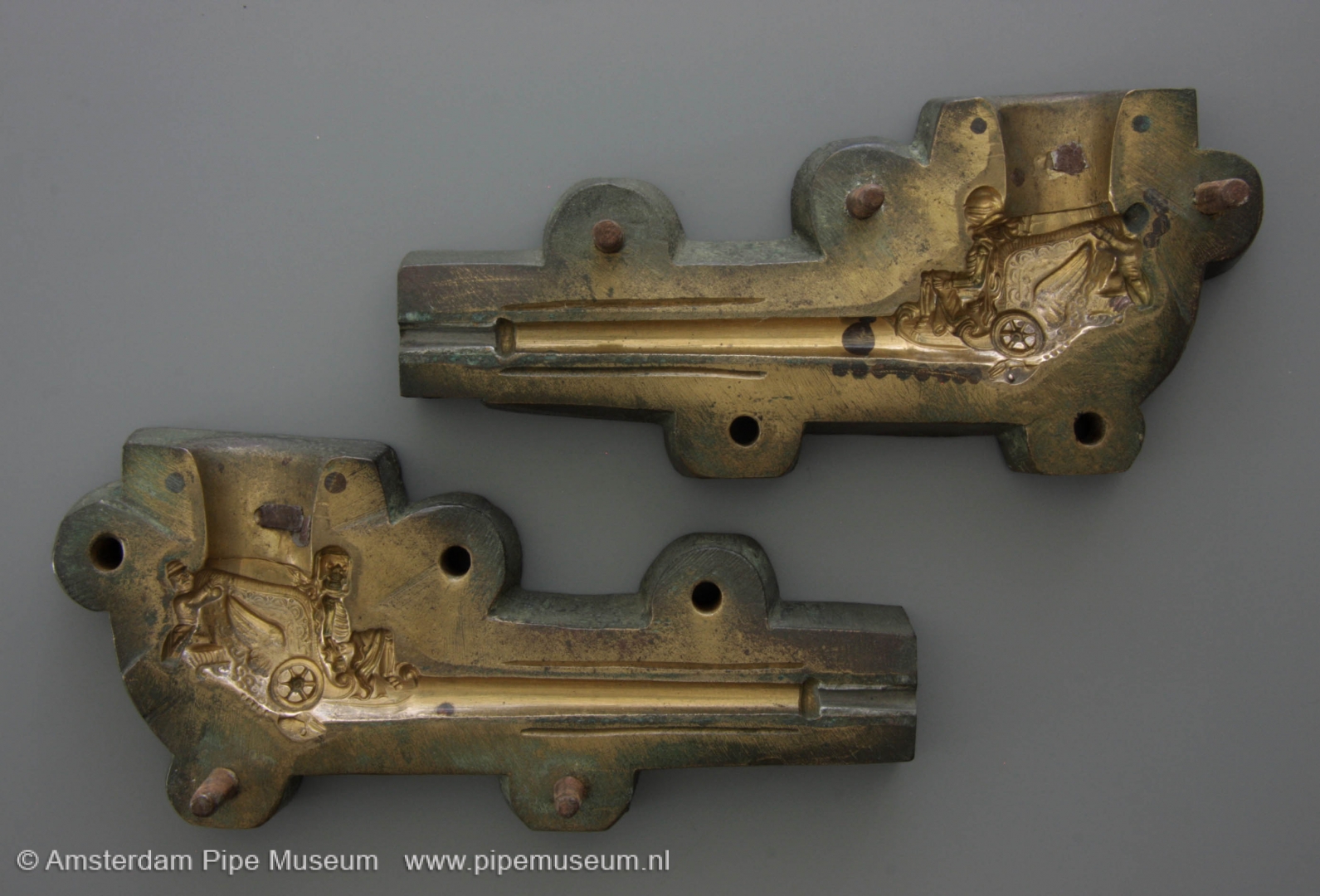

Special tools are needed to make clay pipes. The most important is the press mold or pipe mold. In Gouda it is usually made of brass. Making such a mold is a meticulous job that is done by a special craftsman. He knows how to align the mold halves with each other so that a tight pipe can be made. To pierce the stem, the pipe maker uses an iron wire with a button at the end, the so-called weijer. The pipe bowl is hollowed out with a pipe stopper.

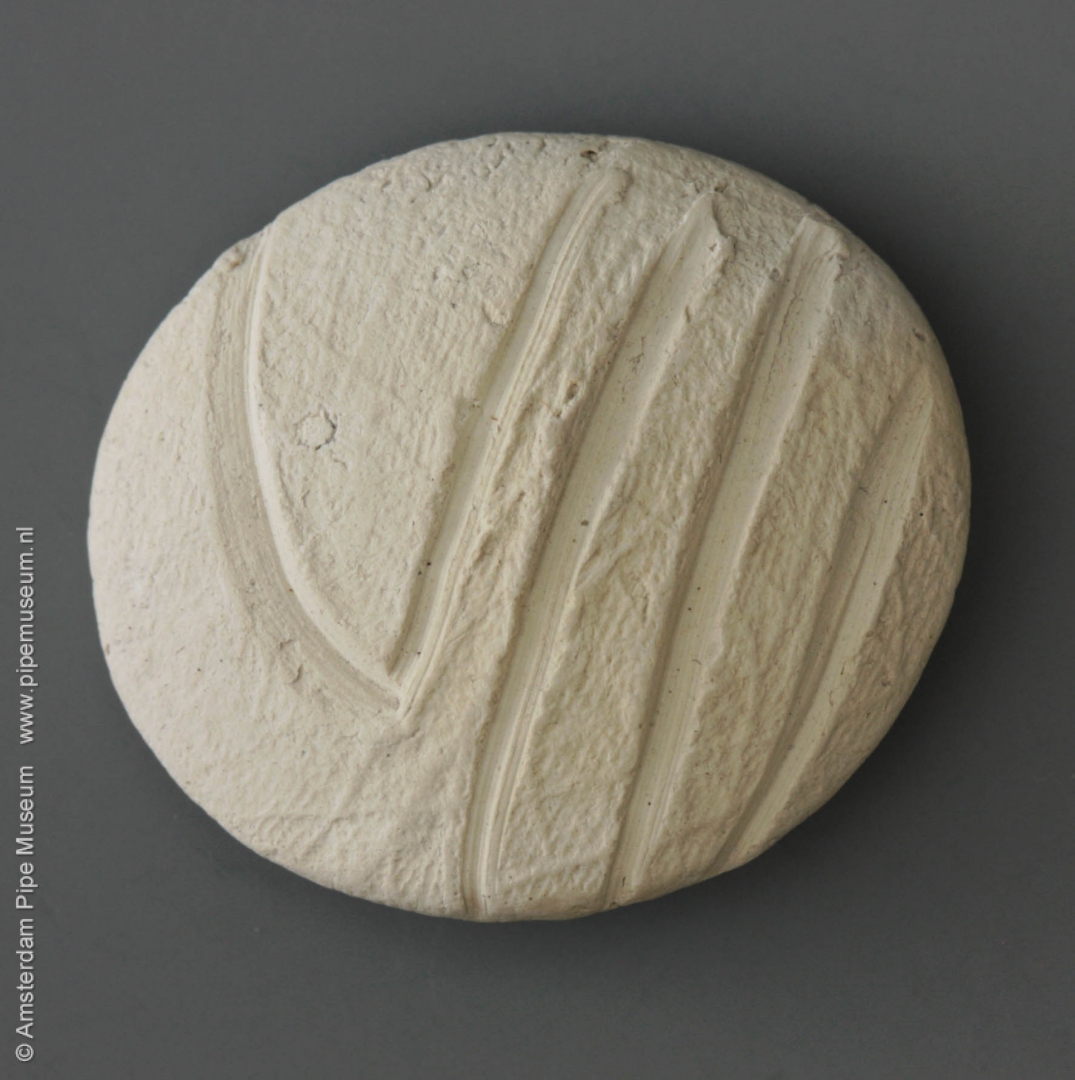

Women and girls do the finishing. They use specific tools such as a botter, a disk to round off the bowl opening and a schenker to smooth the mold seams on the stem. The best pipes are polished with an agate stone to get a smooth and sleek appearance after firing.

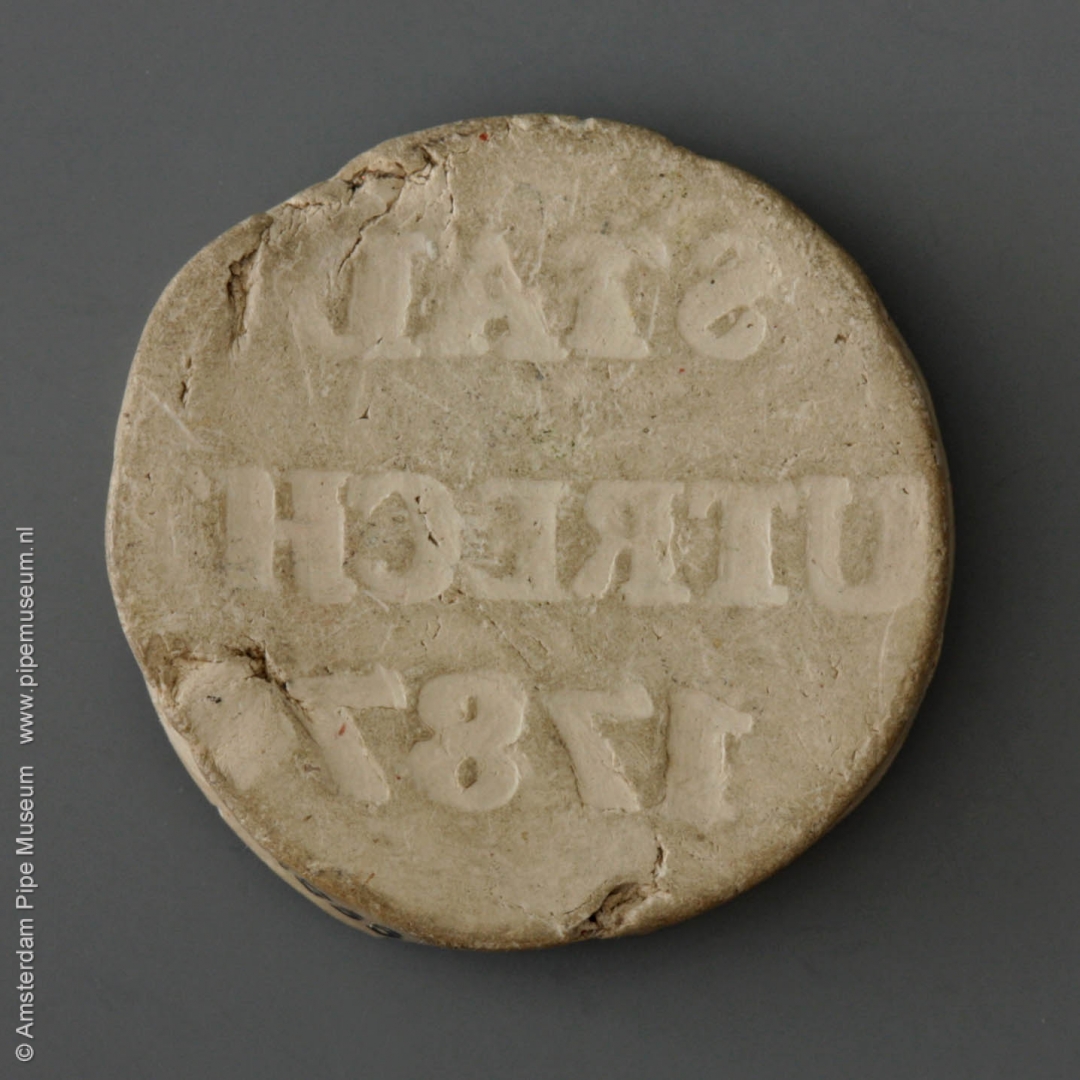

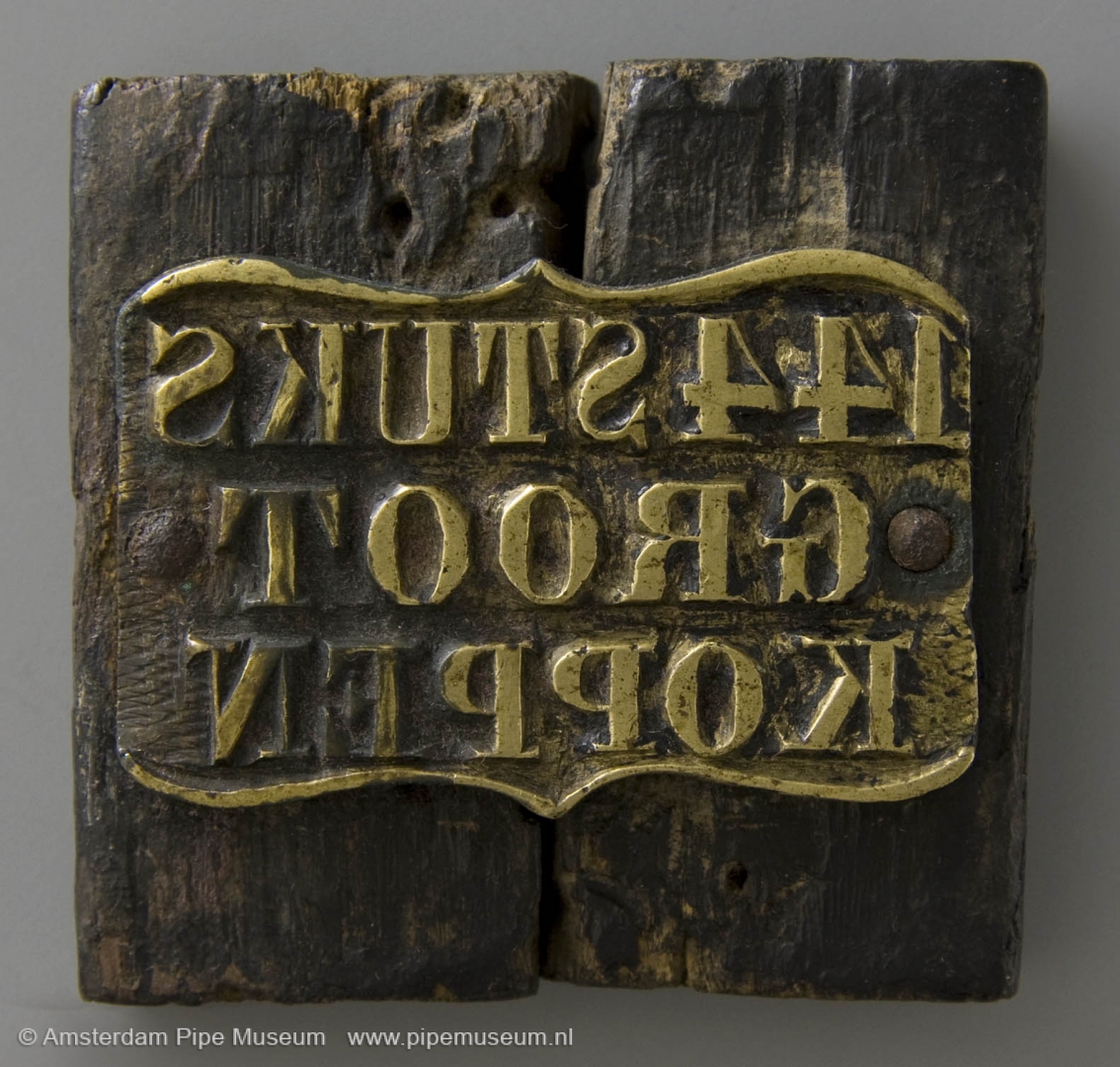

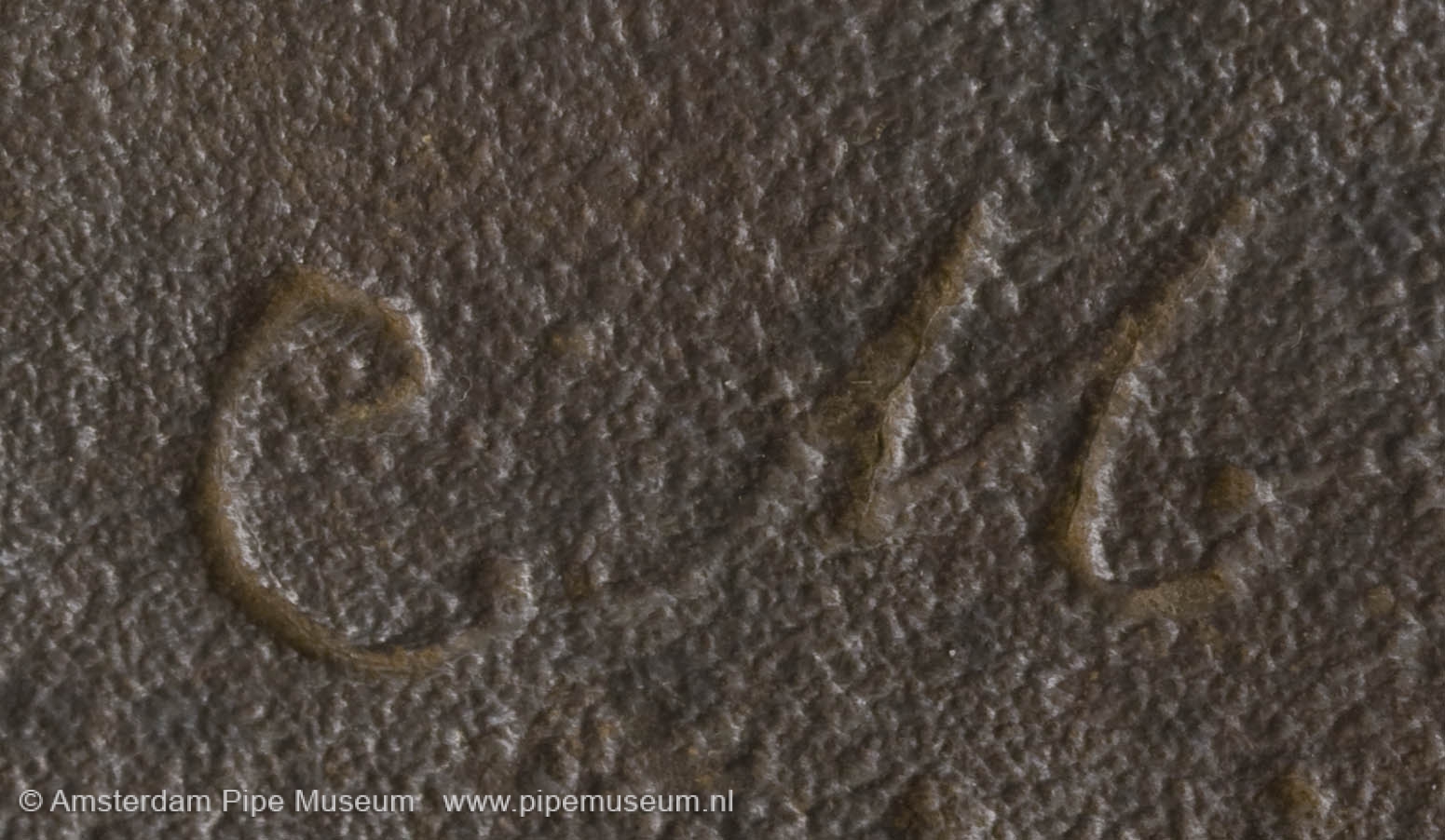

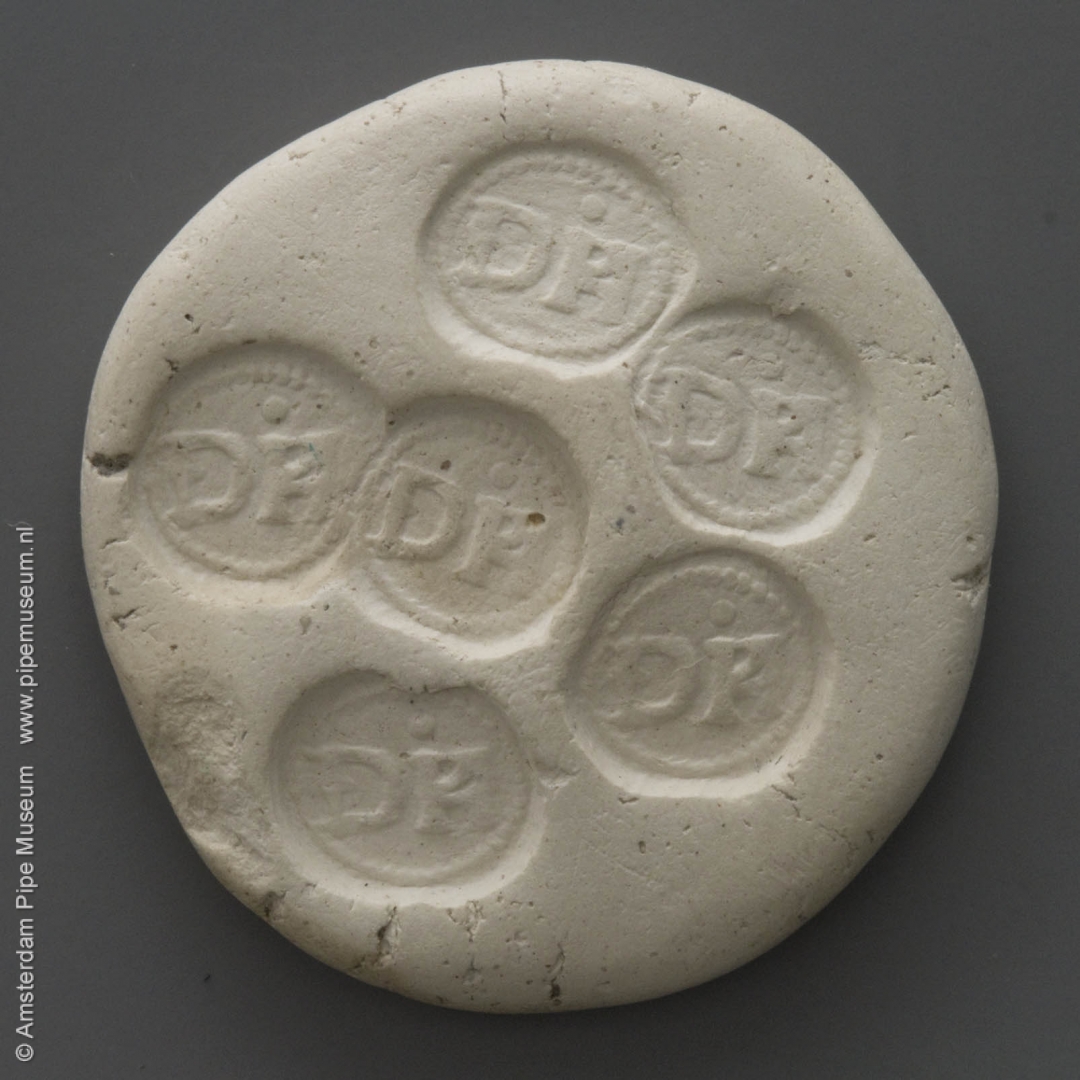

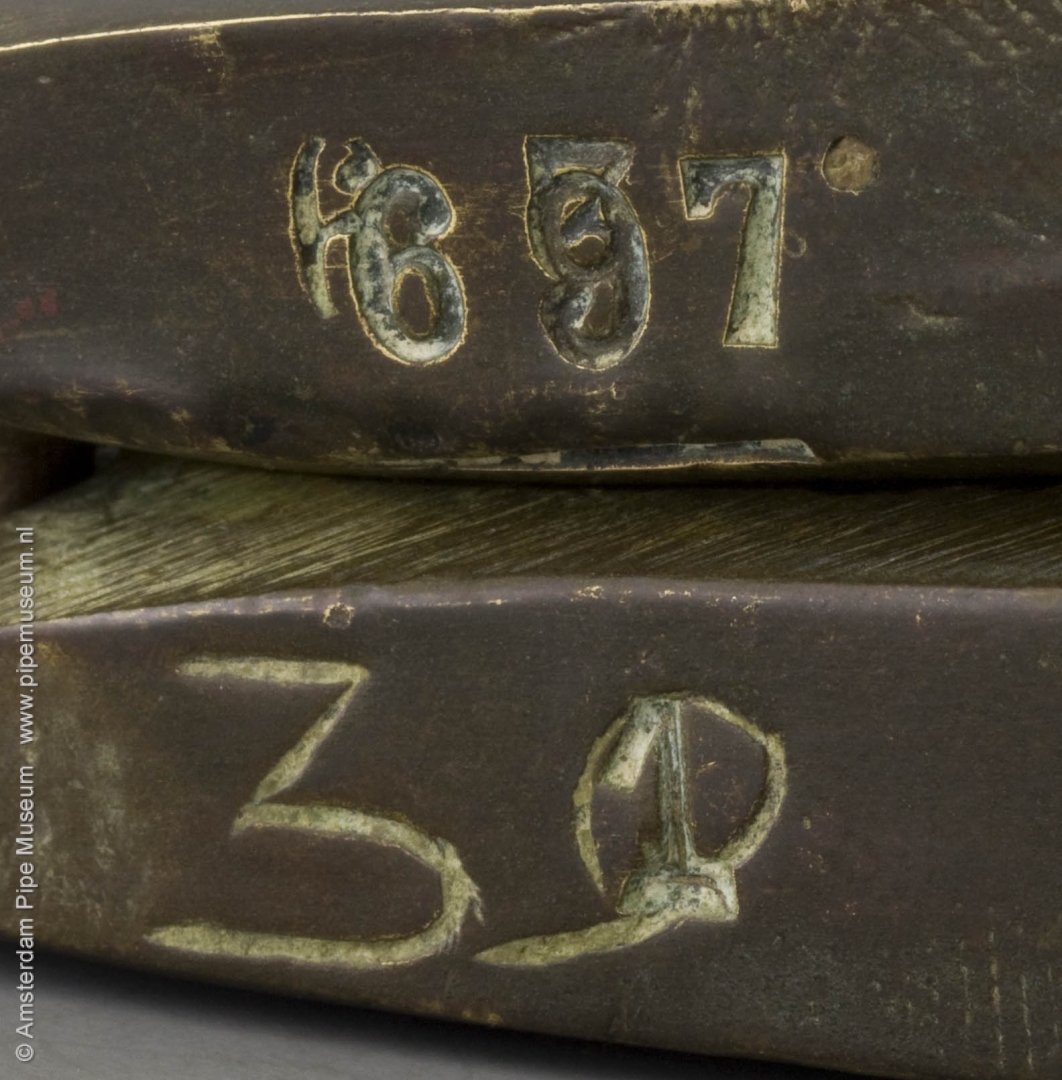

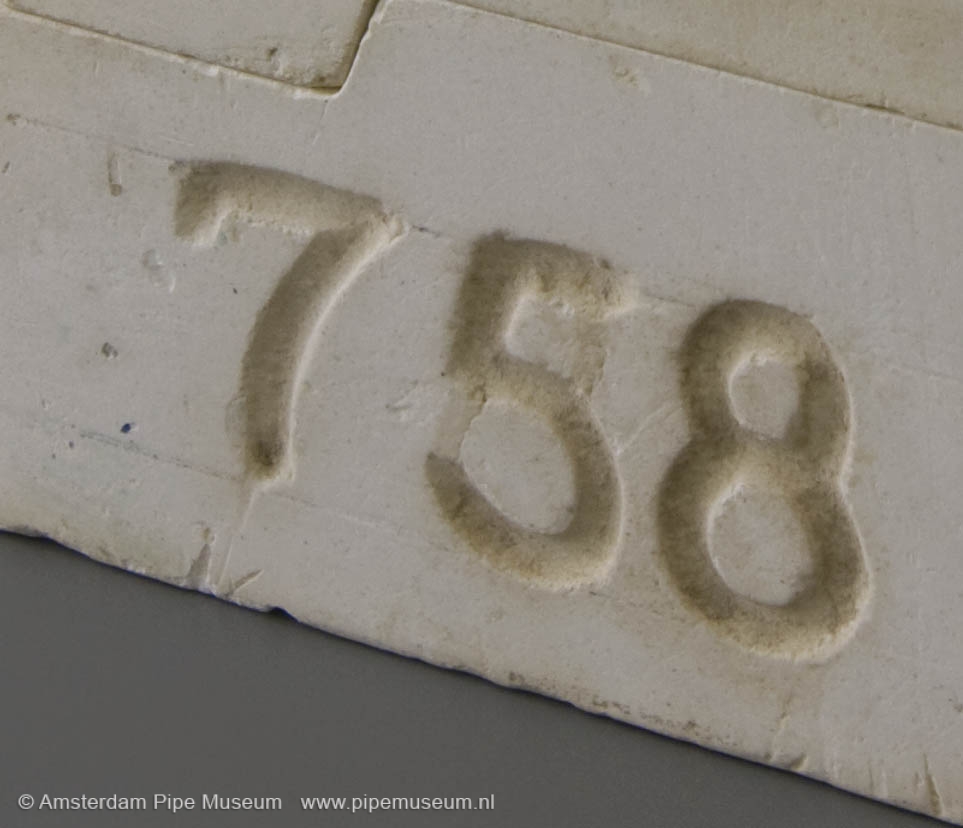

The work in the pipe factory is done at piece rate. Every employee who has worked on a bulk of pipes places his own token with a personal symbol or number with those pipes. After the boss or supervisor has checked the work, the wages are paid based on the number of tokens that came in. It is a practical system that saves a lot of writing and calculating.

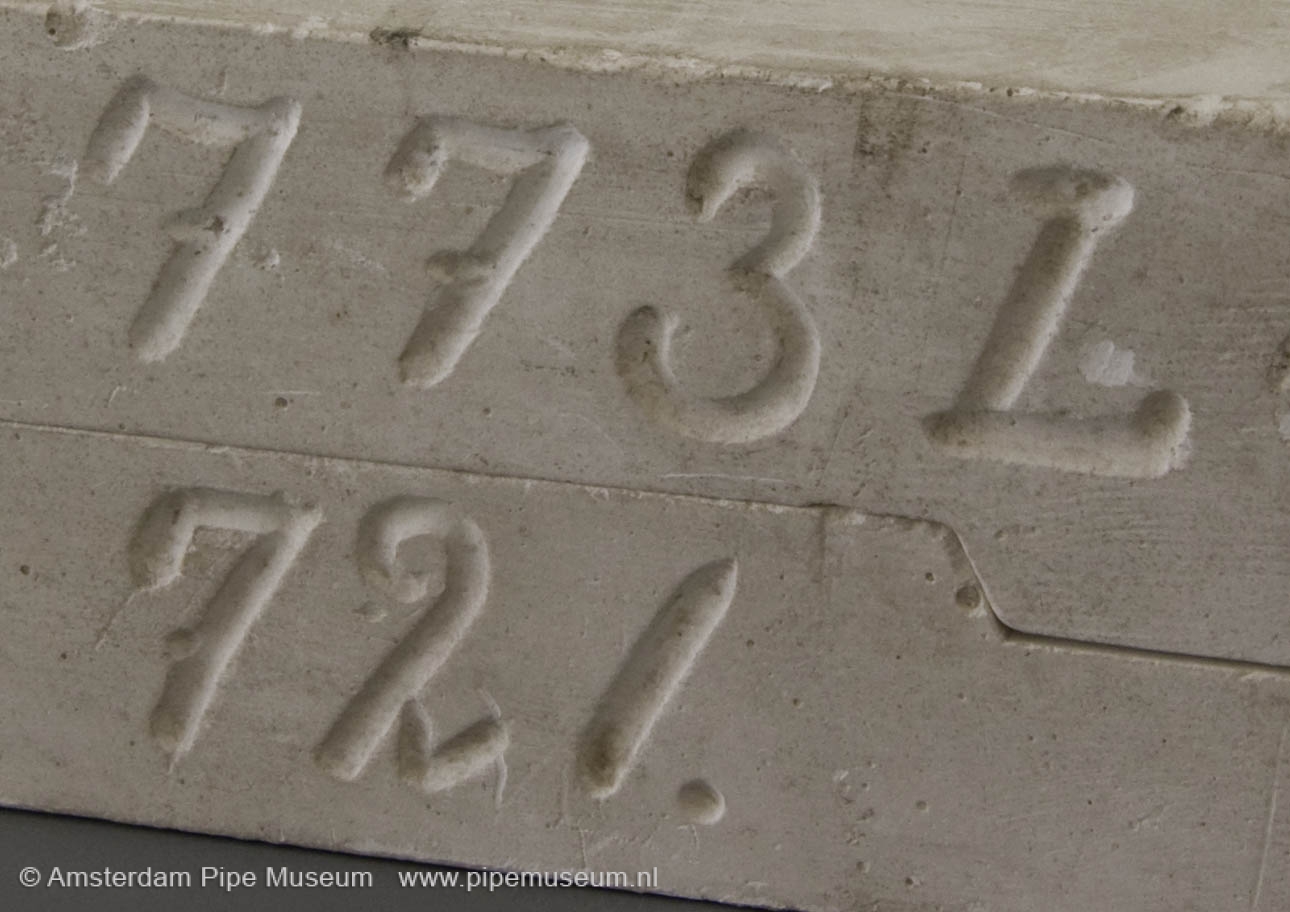

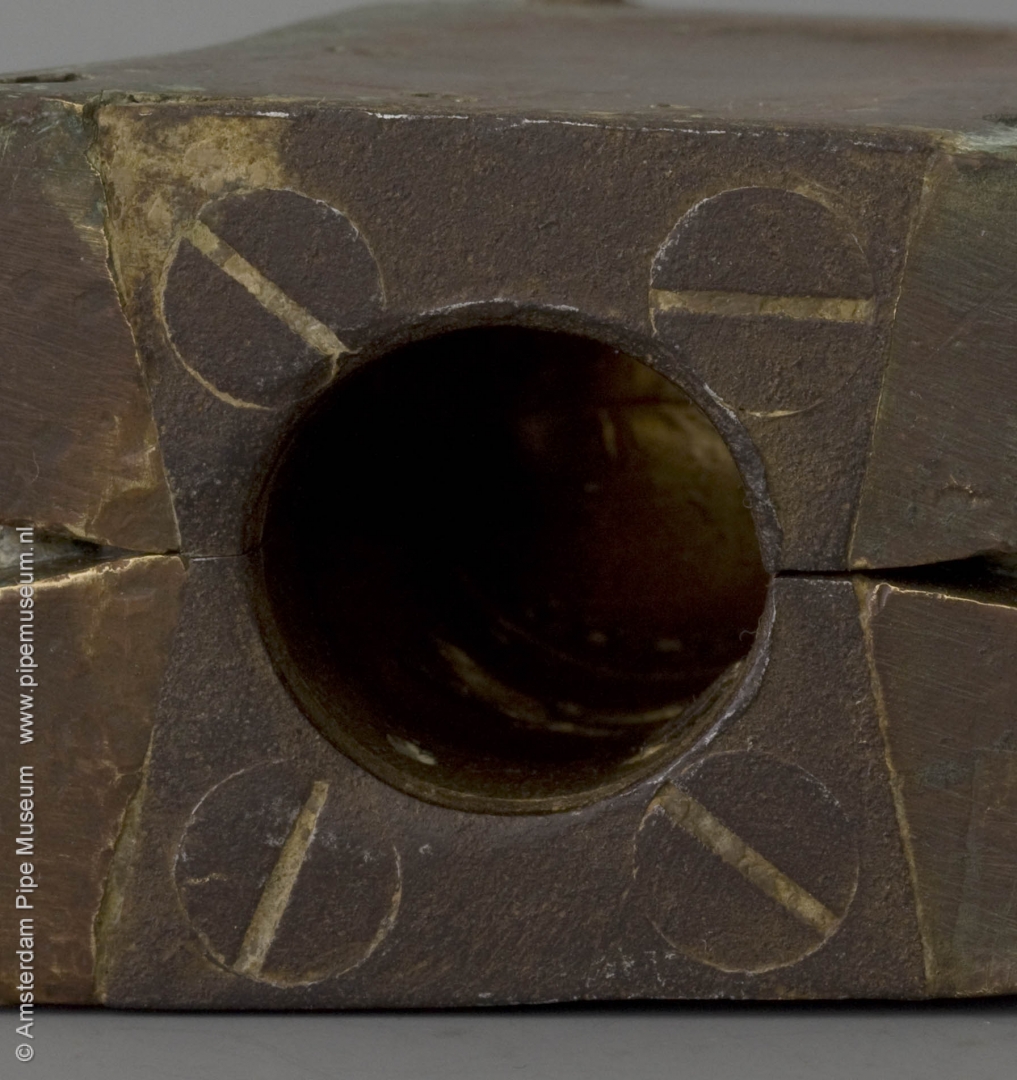

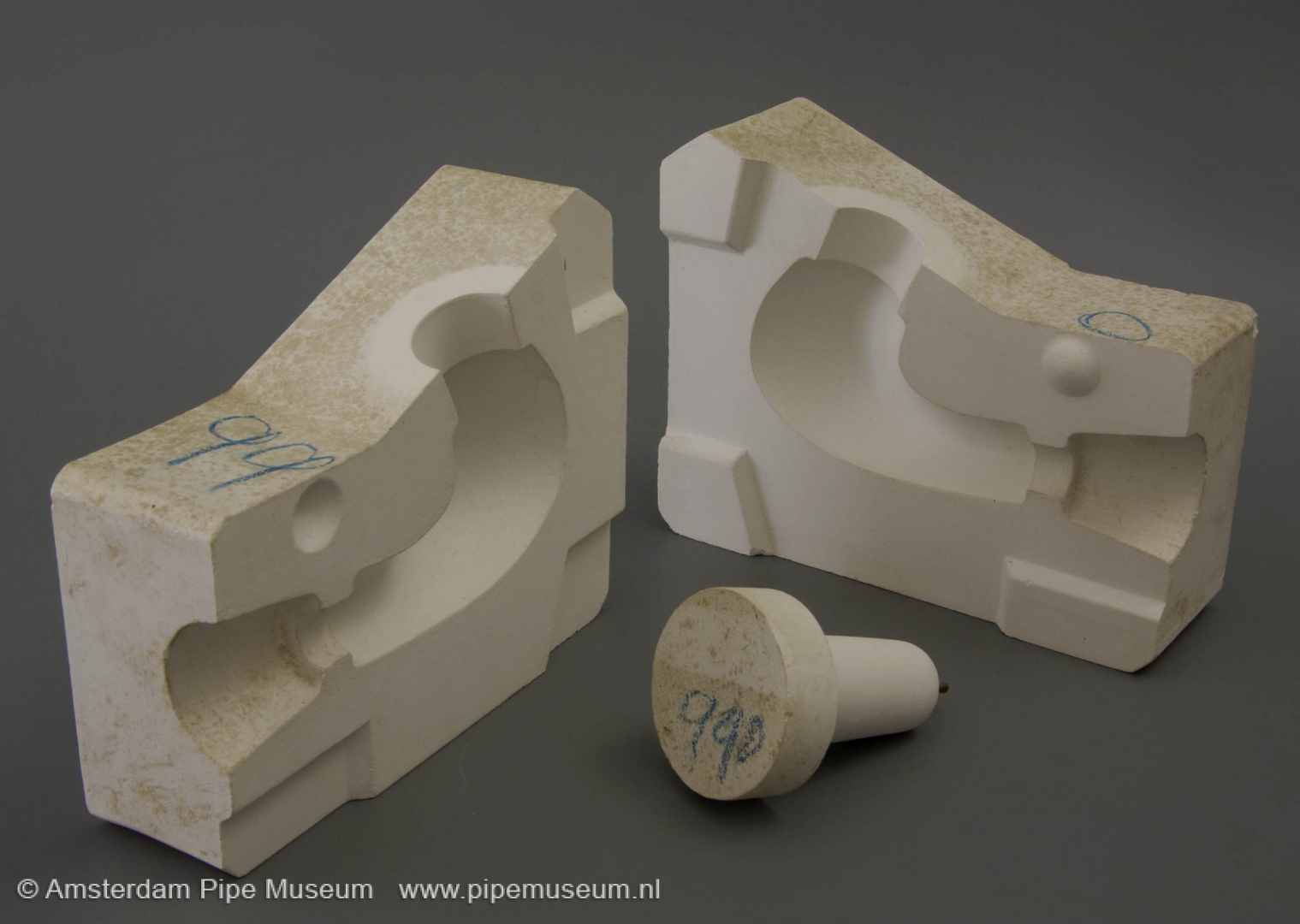

For a truly three-dimensional shaped pipe, a three- or four-piece pipe mold must be used. To make these complicated molds, a master model is made from plaster. Lead models are intended to make a new mold of an existing model later. It was not until around 1900 that plaster molds came into use for slip casting pipes.