The waste dump of Jan Blij, a unique find fully disturbed

Author:

Don Duco

Original Title:

De pijpenstort van Jan Blij, een verkeken kans

Publication Year:

1992

Publisher:

Pijpenkabinet Foundation

Description:

On a unique find from a cellar in Gorinchem, Holland, where a pipe maker dumped his waste over a period of about twenty years. The maker was identified and his assortment reconstructed. The article describes the find characteristic for the Gorinchem pipe industry.

In May of the year 1985, a special discovery was made on the Kortendijk between the Kapelsteeg and the Broerensteeg in the town of Gorinchem also written as Gorcum (Zuid-Holland, the Netherlands). Underneath a demolished building a cellar was found that was completely filled with waste material from a pipe factory. A unique opportunity to learn more about a Gorcum pipe factory. Unfortunately, as if by magic, the site became a place for treasure hunters and the many thousands of pipes that were dug up here spread quickly among the enthusiastic amateurs. In this article I will give an overview of the find and record the information that this find spot yielded.

The find circumstance

The material was found in a rectangular vaulted cellar with a width of four and a length of more than six meters. It is a relatively low basement that had been filled up to just above the groundwater level. Two phases could clearly be distinguished in the bulk material. The upper layer consisted mainly of sand mixed with rubble between which there were a few clay pipes. This material dates from the second half of the eighteenth century, but certainly was not older than 1740. The bottom layer was significantly more interesting. This was a thick package, in places almost half a meter, of very compact shards of saggers mixed with many thousands of clay pipes. The material must have been deposited here over a relatively short period of time and is undisputable waste from a pipe-makers’ workshop.

As noted, the top filling of the cellar was rather heterogeneous. It concerns landfill material that has been brought into the cellar to fill it up permanently and bring it above the groundwater level. Presumably the basement had been under water for some time and it caused nuisance odour and recurrent insect pests. Between the finds of the top layer no clear dumping material from a certain company was recognized, although some unsmoked pipes were recovered. Because there is no correlation in these two layers, it makes no sense to discuss the top layer.

The bottom layer was the result of the disposal of material from broken saggers and clay pipes, mingled with deformed and ill backed pipes that were unsuitable for sale.[1] The total find consists of certainly more than twelve thousand pipe bowls, which must have been deposited over a number of years. It is not easy to understand the reason why this waste has been thrown down at this place. Apparently the basement was no longer usable due to flooding. It seems that the pipes were thrown into the water of the then inundated cellar, batch after batch, as soon as new waste was available with the aim of finally getting rid of the flooding.

Because excavation was done without any system and by many different people looking for that one particular unique pipe, every stratigraphy was lost. In view of the degree of crushing of the finds, it became clear that the waste dump in the basement had never been run over and had not been covered either. When the second filling layer has been poured over it, hundreds of rejected pipes must still have been unbroken. Only due to the pressure of dumping and later walking a lot of material got broken. Later, treasure hunters in their haste caused more breakage until everything was disrupted and removed by the excavator.

The finds

All the material belongs to the quality category grof (litt. rough), it concerns simple clay pipes with a relatively short stem that have not been stroke burnished . Generally speaking, the production is divided into two types. The first and largest group consists of simple coarse pipes without specific decoration, the second much smaller group of pipes of the same shape with a side decoration of a Tudor rose with dot leafs or the representation of a standing Dutch lion.

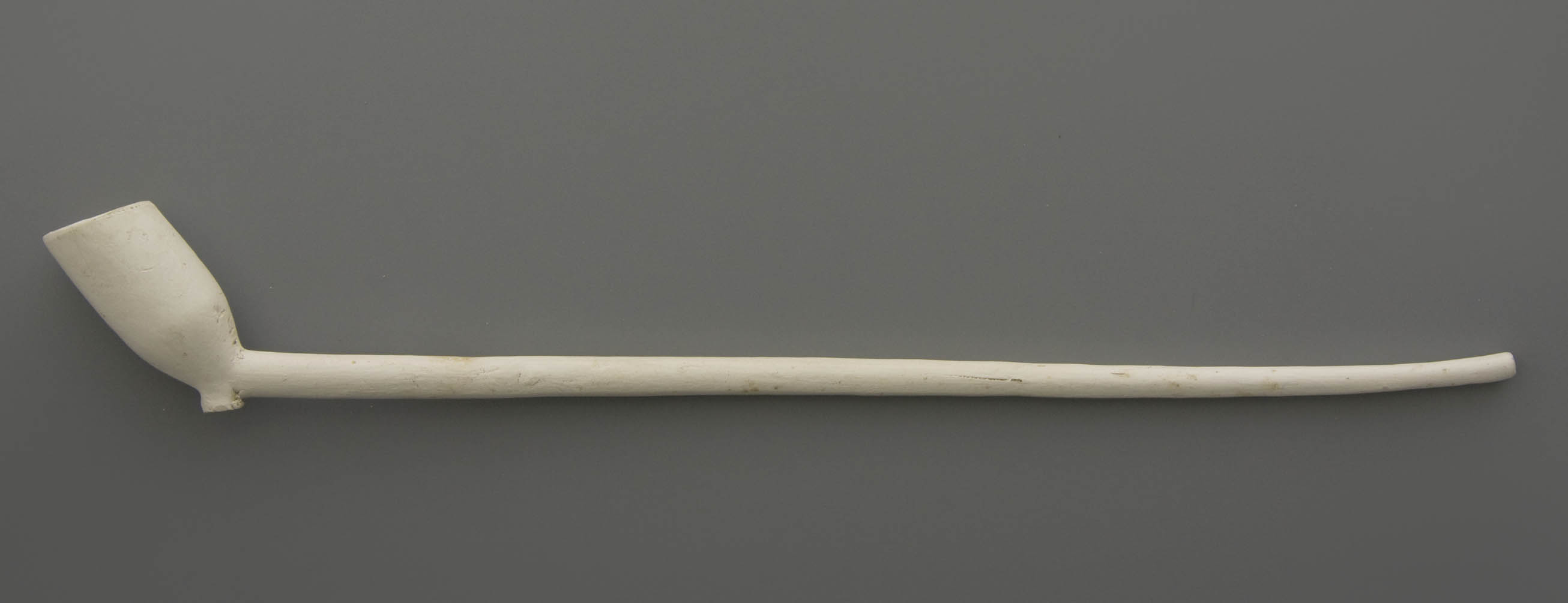

The undecorated clay pipes have a funnel-shaped bowl (basic shape 2) with a not very powerful design and rather wide bowl opening (Fig. 1). Judging by the outbalanced shape and the large size, these pipes should typically have a spur instead of a heel. However, this is not the case. The majority has a rather pronounced heel. The pipes are distinguished by small differences in bowl shape, but especially the shape and diameter of the heel. Furthermore, they carry simple mould marks on the side of the heel.

The differences in detail give us the opportunity to learn more about the number of various press moulds used, which must have been considerable given the wide variety of bowl styles. However, it is important to pay good attention. By cutting down the crown of the pipes when the clay is still soft, and rounding off the rim one bowl became lower than the other. The same happens with the heel that was cut off by hand, which was not always done at exactly the same height. A less experienced researcher will assume more press moulds than the more expert person who knows how to reduce the differences in finishing to the same press mould.

The finish of all these pipes corresponds to the quality. As stated, these are simple pipes of coarse quality. After press moulding, the stem was cut to length and the mould seams smoothed out, the bowl was rounded with a so-called botter, a disk shaped instrument. Then a milling is applied to the stem side of the bowl, only visible for the smoker. Among the pipe find were also some specimen that were not provided with a milling and thus belonged to a slightly cheaper quality.

The undecorated pipes have so-called mould marks of an extremely simple nature. Mould marks were used in company to indentify the various employees who worked on a batch of pipes. We distinguish a single dot to the left of the heel, a dot on either side or a dot on the right side of the heel. Together with the pipes without a mould mark four press moulds were in use at the same time.. This makes it possible to guess whether four casters have worked on this model or that the moulds have been used by, for example, two people over a longer period of time.

Finally, a part of the pipes show a centre of gravity stamp that in this case is placed relatively close to the bowl. The oldest version consists of a series of millings fringed with a chevron or zigzag pattern, the later style to which most of the pipes belong have a pearl fillet instead. With the scarce complete pipes that have been found, it can be established that the gravity decoration is sometimes placed too close to the bowl. The centre of gravity is applied only by one third of the undecorated pipes.

A second category of simple pipes is provided with a rose motif made up of six dots around a central dot, on both sides of the bowl (Fig. 2). In the first quarter of the eighteenth century, this motif has a last revival as a variant of pipes with an embossed bowl mark. It is a decoration with a certain functionality, because the dotted rose improves the grip on the bowl for the smoker, especially if the pipe had become hot due to hasty smoking. Overall, the appearance of these rose pipes is more modern. The size is a little smaller which brings the overall shape in a better balance. The heel is also more refined so that it can justly be indicated as a spur.

The undecorated coarse clay pipe has been found in larger numbers than the rose decorated ones. It appears that these rose pipes were marketed as smaller and more sophisticated products not as much in demand as the plain pipes. For that reason fewer press moulds of this type were in use. The fact that they rarely show mould marks also indicates a smaller production. If a mould mark is used then it is a single dot on the left side of the spur. The restricted variation in mould marks may also mean that the manufacturer could trace the workman in question on the disposition of the rose mark if he had complaints about the work. In the end, that was the only intention of the mould mark.

The most remarkable pipes in the find and in fact the only one in which the treasure hunters showed interest are the pipes with an embossed bowl. Again, the variation in motives is restricted. It is exclusively a climbing lion, only in the detailing any differences can be distinguished. It seems that this decorated pipe was provided as a gratuity with a certain number of ordinary pipes. In addition, they will also be delivered per gross, since the number found was more than a few percent. Because most of the diggers have only picked out the decorated pipes, the ratio in decorated and undecorated in the find quickly became completely distorted.

Chronologically, four types of lion pipes can be distinguished. The earliest version shows a standing lion on either side of the bowl, turned to the right on the left side and turned left on the right side so that both animals are facing the smoker . When the press mould was still fresh, these animals were sharply cut in a semi-realistic style characteristic in heraldry (Fig. 3). The posture of the lion is convincing and the display of the skin striking, on the other hand, the head of the animal is somewhat rough and awkward including a small crown. With the wear and tear of the press mould, this motif gradually fades into a poorly recognizable decoration. The seams of the bowl are lined with dots or pearl edges.

A second version of this press mould shows the same representation of the Dutch lion, but now it is slightly adjusted. The main change is that the lion gets a sword in his raised claw (Fig. 4). The engraving is more conspicuous with a higher embossment but explicitly fewer details. Both type 1 and type 2 have a rather shaky designed, small amorphous bowl and because the heel is often cut off equal to the stem, the separation between bowl and stem becomes somewhat unclear.

More detailed and probably dating a few years later, pipes occur with the same lion but now without a crown. The animal is placed between branches with leaves alternating with Orange apples (Fig. 5). Adding the leafy branches has led to omit the pearl rows on the bowl seams. The shape of this pipe bowl has clearly become stronger and more balanced, a change that can be traced back to the Gouda decorated pipe of ordinary quality. The rather formless Gorinchem bowl shape is finally abandoned, although the explicit heel still remains.

The most recent version of the embossed clay pipe shows the crowned lion again between branches with leaves and Orange apples. With this version, the bowl shape is again more strongly related to the Gouda pipe and the heel has definitely changed into a spur. The lion, however, is somewhat smaller which leaves the top of the bowl undecorated. At a later stage, pearl rows have been applied very carefully to the bowl seams. The pearls fall partly over the leaf branches and the careless spectator quickly interprets these beads as Orange apples (Fig. 6).

The standing lion refers primarily to the coat of arms of the province of Holland. In addition, it seems very likely that the lion has had a pro-Orange meaning, referring to the stadtholder of the House of Orange. Notably the reference to the House of Orange through the branches with orange apples is evident. Some of these decorated pipes are provided with a band stamp on the stem, where they are linded with chevrons. In the Gouda industry it is not customary to put a band stamp on the stem of coarse pipes, albeit decorated. In Gorinchem those rules were not so strict. A motif characteristic for the fine quality was applied to the coarse category without pardon.

The embossed pipes also show mould marks. The earliest specimens have a single dot or dot with a moon on the reverse above the spur. In the lion of type 4 the right side carries a sickle-shaped moon. This mould mark indicates a somewhat later date. We get the impression, however, that these mould marks were applied more out of a habit than with the motive for distinction for the factory manager.

We can see that all pipes from the landfill were retailed with and without a band stamp around the stem. It seems that the specimen with a band stamp are in general of slightly better quality for which reason a stem decoration was applied. This could be an indication for differences between the employees, meaning that the better pipe moulders cooperated with the better women that finished the pipes in order to provide the better quality product, while the sloppy moulders made the cheaper work, the women at the same time saving on the finishing operations.

Despite the rush of excavation, which resulted in large-scale fracture of the find material, information about the stem length of the pipes can still be given. It appears that the stem length of all species is between 16 and 23 centimetres. The rose pipes have been the shortest and measure an average of 16 centimetres. The pipes with the standing lion also belong to the shorter species and vary from 16 to 17 centimetres. Only the undecorated pipes have the standard length of the coarse pipe with 23 centimetres stem length. In conclusion we can state that the total production comprise pipes shorter than average, certainly in comparison with the Gouda counterparts of that time. Both the length and the quality made these pipes more suitable for the tobacco bar or inn than for domestic use.

The maker

Thanks to data from the archive, we know that Jan Blij, officially Jan Jansz. Blij lived and worked in this place from 1693 onwards. Blij was born in Gorinchem in 1658 as the son of Jan Blij and Margriet Davidts Brown, his parents originating from Scotland. We can only guess at the original Scottish spelling of the name Blij. It is also unclear whether his parents were already working in the pipe-making industry and thus belonged to the English-Scottish immigrants who brought the craft in Gorinchem. In 1684 Jan Jansz. Blij married Anna Maria Claas van Jas, probably from the town Zutphen. At least eight children were born in this family between 1685 and 1699.

In 1693 Jan Blij buys the house on Kortendijk west side where he will live with his family and where also the pipe-makers’ workshop is located.[2] The building has the name 't Groote Molenijzer and was connected to the Broerensteeg by a corridor. A few years later, in 1697, Blij bought a house – or at least a building – on the same Broerensteeg.[3] The purchase price only consists of the overdue taxes. We can assume that his company flourished during that period, so he could extend his business in the new property.

Little is known about Blij's life. The most interesting fact is that the innkeeper Alexander Hutsenson in 1702 demanded from him and his colleagues Roelof van Beest and Christoffel de Hoog payment for consumptions in his establishment.[4] The fact that the former guild board is mentioned in the deed indicates that the pipe makers' guild then apparently had been dissolved or was no longer active. The gentlemen are summoned to pay the bill together. The deed is especially remarkable because, after having established a guild for pipe makers in Gorinchem in 1656, we hardly find anything more about it in the archives. Socializing during the evening hours was apparently one of the most important, but only incidentally recorded activities.

Blij has been pipe maker throughout his life. For example, from 1725 a learning contract is known, in which he promises a sixteen-year-old orphan boy Jan Ophuizen to learn the craft of pipe making.[5] The agreement mentions among other things the salary set for the first year at thirty guilders, the second year the boy receives six guilders more and in the last year he receives 40 guilders. We can safely expect that one or two pupils have worked continuously in his workshop. In view of the simple quality of his products, a pupil could soon cooperate, but the question is whether his workshop could offer a good learning experience considering that the quality of the pipes was poor.

Jan Blij continued his business until his death. Given his age, it seems logic that he would gradually withdraw from the business, but there is no proof for such statement. From the apprenticeship of 1725 we note that he is still fully active. Blij dies in 1727 and is buried the same day as his wife. One year after his death, one of his two daughters, namely Clasina Blij, marries with the pipe maker Christiaan Wouters. Possibly this Wouters was already working as a journeyman to her father and it seems that they will continue the business of the deceased. In 1735 Christiaan Wouters buys the building on the Kortendijk.

A closer look at the find material

The immense amount of material not only gives us insight into what Jan Blij manufactured in his company, but also the problems they faced. We see that this Gorinchem workshop focuses on production where speed goes above quality. The numerous pipes that have been rejected are evidence of this haste. The most obvious are the bowls that have become oval or deformed in some other way (Fig. 4). This defect happened to the man who moulded the pipes being too careless when removing the pipe from the mould or by putting it on the shelf to dry. The women who finished the pipes could as well cause deformations. Eventually these deformed pipes were separated during packaging and thrown away later. Whether the boss appealed to the workmen and actually deducted the loss from their salary, as a Gouda pipe maker would do, remains a question. In principle the boss was well capable to trace the responsible worker, thanks to the mould marks.

In addition to deformations as a result of haste, we see pipes with defects caused by careless wiring, making the smoke tube in the stem by using a wire. Occasionally the iron wire was too nonchalantly pressed into the clay roll causing an a-centrically stem bore that came too close to the surface or, worse, gave a perforation. Another problem could be the hasty pressing of the stopper into the press mould, either too deep or crooked. As a result, the bowl wall became very thick at one side and too thin on the other, sometimes even resulting in a hole at such location.

Other problems that the finds show are working with clay that is not plastic enough or badly ground, which could cause cracks in the product. Cracks can also be caused by uneven drying, for example in the draft (Fig. 7). Pipes that did not go completely dry in the kiln have a great risk of discolouring orange or yellowish, which we also encountered on several occasions. Furthermore we see characteristics of impurity or pollution of the clay, either by burned-out organic dirt or grit and stones. When such inclusions occur in the stem, they cause an increased risk of breaking.

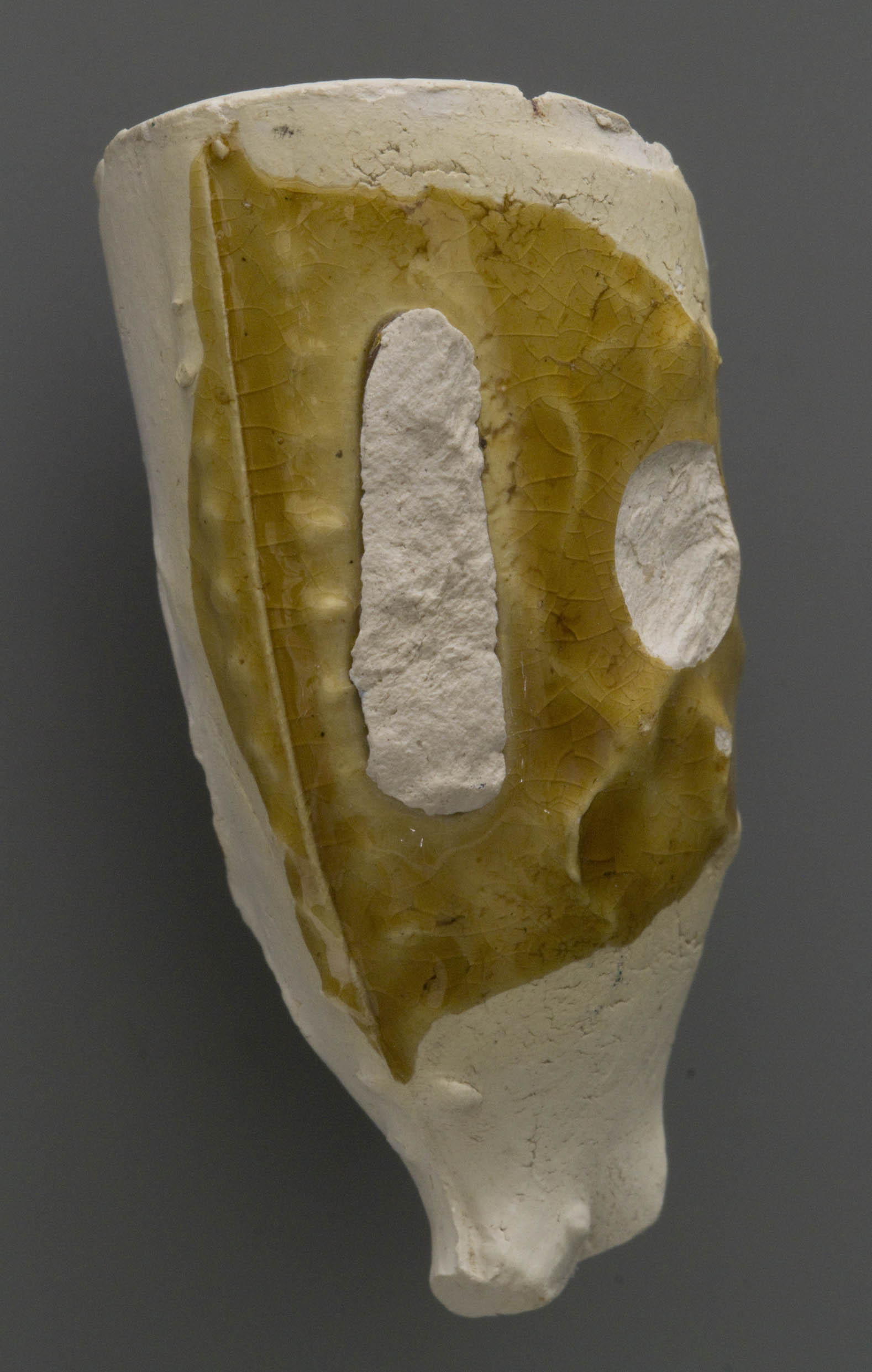

A remarkable amount of material exhibits contaminants with lead glazing (Fig. 8). The fault was not with the workmen of the pipe factory, but with the potter. In Gorinchem it was customary that the saggars holding the unbaked pipes that were standing on the bottom of the kiln were covered with roof tiles or pot covers, or at least the potter was obliged to do so.[6] At the maximum temperature of the kiln, the lead-glaze of the earthenware that filled the upper half of the kiln melted and inevitably started to drip. The cover of the pots had to prevent the glaze from running between the pipes. However, even when the kiln was filled, more than once there was nonchalance or haste and due to the poor coverage of the pots the glaze leaked over the pipes. We see spatters and spots from small to large.

Striking in the landfill are the pipes that are glued together by an excessive amount of glaze leaking into the sagger, sometimes to lumps up to eight bowls (Fig. 9). They indicate how damaging the leaking of the glaze was for the pipe maker. Of course, whenever possible, these pipes were split to be sold as a second choice. But often with this attempt of loosening the stems finally got broken.

In fact, the pottery consisted not only of earthenware covered with an almost transparent lead glaze. Since numerous recovered pipes show traces of a brown lead glaze we can conclude that dark brown glazed pottery was also part of the production. Although some pipes got almost entirely glazed by accident, it is certain that Blij did not produce fully glazed pipes. In fact, his product was too simple for that.

More about the business

Now that we know who the maker is and what the product range was at that moment, it is important to come up with a date and say more about the pipes in relation to the period of origin. It is certain that the material must have been deposited between 1693 and 1727, assuming that within these years Blij exercised his business on this location. In terms of shape and decoration, the findings confirm this dating, because the material shows all the characteristics of the first quarter of the eighteenth century. Given the large unity in the finds, it seems that this waste dumping took place over a rather short period of time.

The decorated clay pipes provide the best chance for narrowing down the dating, because a sequence of four models can be determined. In terms of shape and primitive engraving the oldest type with standing lion sits between the decorated seventeenth century pipes and the well-developed bowls with spur that came onto the market around 1710. We can expect that this model will be introduced around the year 1700. Type 4 with its fully developed shape with strong Gouda characteristics remains in production until about 1725. This means that the decorated material spans almost the exact period of time Blij worked on the Kortendijk.

We can also reconstruct the duration of the waste dumping in the cellar based on the decorated pipe with the standing lion. A regular press mould lasts an average of one year; a decorated shape, on the other hand, is usually not permanently in use and therefore functions over a longer period of time. The four press moulds Blij used will have served about three to four years each. In this way, the four decorated pipes would stand for a production period of about fifteen years. Set in time from 1700 to about 1715 with a run-out to 1720. When the decorated moulds would last for six years, the find covers the entire work period of Jan Blij.

Certain is that the excavated pipes were thrown away the moment they returned from the potter, immediately after they were removed from the saggar. It was normal to check the products after firing. After the check they were prepared for retail packaging and the rejected pipes were removed from workshop. It remains unclear which part leaves the business as a second choice, but in the case of Blij this could have been quite a substantial number. What was rejected was definitely unusable and thrown on a heap to be removed later. When the cellar was flooded, it was decided to dump the waste there, until the problem of flooding was over. In the end it turns out to have become a long-lasting habit.

The percentage of rejects is difficult to determine. In ongoing production, this is generally considered ten percent for the moulders and also about ten percent for the women who finished the pipes. Even the filling of the saggars will inevitably have given breakage. Logically we don’t find these failed pipes since they were not baked; the moulded but unfired pipes will turn into unrecognisable lumps of clay. Once the pipes have been placed in the saggar, the risk of breaking has passed. The baked pipes are far more break-resistant. There will be still minimal risk of breakage in the careless unpacking and some production errors that only manifest themselves in this stage. With this finding it appears that glaze contamination was an important reason for refuse. It is not easy to give a percentage for this debris, since it cannot be expressed per saggar. The leaking of glaze in the pot is rare, but if it occurs, it is suddenly a waste of a few percent. To set the failure after baking at less than one percent therefore seems justified.

Although we cannot rely on exact figures, making a calculation on production may be interesting. When we set the number of pipes in the cellar at 12,000 and assume less than one percent breakage when unpacking the pipe pots and rejecting unsmokable ones, we can recalculate the waste to the total production from which it originates. The entire production behind the basement would be over 1.7 million pipes.

The next calculation is to determine how that figure relates to the workforce. The starting point is the assumption that the factory has worked with a maximum of six men who did the moulding, four of which made the rough, undecorated pipes and two on the rose decorated pipes alternating with the embossed pipes. A maximum of 40 gross clay pipes can be made per moulder per week. On six pipe moulders, the weekly production is 240 gross, which gives a production figure of 12,000 gross per year. Coincidentally, that outcome is equal to the 1.7 million pipes. Unfortunately, this sum does not match the calculated production period of the decorated bowls. It is possible that more fracture material has been deposited elsewhere, although this does not seem so likely.

If the above figures are correct then the total deposit would have been done in a one year time. To allow this figure to match the calculated period of dumping of at least fifteen years, we have to make some substantial adjustments in our calculations. First, the workforce cannot be six but let’s say four moulders. Moreover, in the eighteenth century the weekly production was probably considerably lower than the nineteenth-century figures that are the only archival facts we have and did use.. Finally, the failure rate of less than one percent can still be too high. Once recalculated, the dumping period will then be three to four years. Whatever the case, even then the size of the landfill does not match the dating of the pipes.

Final word and conclusion

It is extremely regrettable that this exceptional find has been disrupted by the local diggers and that the material was completely dispersed. Fortunately, it has been possible to record the primary information about this basement content in order to get some basic information of Jan Blij's workshop including his assortment. The systematic excavation and further study of the pipes would have given a unique opportunity to gain new insights with this immense batch of pipe material such as the wear and tear of the press moulds, the pattern of sharpening and repairs and the moment of substitution of the moulds. Moreover, with careful interpretation, the size of Jan Blij's production certainly would have been retrieved, including the percentage of rejects.

The countless misfired products of this immense find have at least made clear to us what problems there have been with the baking method in Gorinchem. The poor covering of the saggars or even lack of it must often have been a reason for disputes, for which the records also testify . The strikingly large number of pipes with glaze splashes or stains in yellow or brown colour proof that the potters in Gorinchem worked sloppily, with the result that the lead glaze earthenware under the kiln dome contaminated the pipes. It is unclear whether this has been a constant problem or has only occurred a few times, for example when changing the men responsible for the firing process or by succession from one potter to another.

Logically spoken, the find spans a period of about fifteen to twenty years and it is remarkable that we hardly see any changes in the assortment. The various pipe shapes remain the same and only changes in minimal details of the pipes occur. Especially the pipe with the lion decoration shows nicely how the bowl style and decoration gradually change and adapt to fashion. We can see that the decoration of the four types of pipes with the embossed climbing Dutch lion extended little by little: the addition of a sword, then the branches with Orange-apples and finally branches accompanied by a pearl-hem. In the meantime, the shape also evolves from primitive to the balanced Gouda appearance.

The range of pipe shapes is representative for the pipe makers in the city of Gorinchem, where production predominantly focused on the cheaper, less refined products. This is also demonstrated by Jan Blij’s assortment. Three variations of pipes are concurrently available: a rough undecorated one, a product with dotted rose and finally as a luxury a pipe with a decorated bowl. The vast majority consists of undecorated pipes, some sixty to eighty percent. This is supplemented by about twenty to thirty percent of pipes with dotted roses. Finally, about five to ten percent of the pipes are decorated with the standing lion. Apparently these three species met the market demand and there was no reason to adjust this assortment.

Striking about the discovery is that the entire assortment fit in the same quality and that within this category there was a relatively small but evident distinction. We see this pattern more often when reconstructing the assortment of a pipe factory. The maker does not focus on the widest possible variety in clay pipes, but focuses on pipes that are closely related to each other. Within that specialism he offers his assortment with subtle but clear differences. This way of working also ensures that his workmen have to work in the same discipline and those who can produce better work will go to another workshop where production is on a higher quality level.

The company of Jan Blij is therefore characterized by a large unity in the market supply. Although there is variation, the pipes are close to each other in qualitative terms. We also know this same method of working at pipe makers in Gouda. A maker like Arend van Dijk also produced four closely related pipes at the same time.[7] However, this company even produced a standard 50 centimetres pipe of quality with a stroke burnished bowl and heel mark for which the boss or main moulder was responsible. In view of the more simple nature of the industry in Gorinchem, such a product did not fit into the company profile of Blij.

© Don Duco, Pijpenkabinet Foundation, Amsterdam – the Netherlands, 1992.

Illustrations

- Short coarse pipes of ordinary quality with undecorated bowl. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 1.496a-d - Pipes of ordinary quality with on the bowl sides a dotted rose motive. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 1.403k, Pk 1.496ef - Pipe bowls with on either side a climbing lion with crown, type 1. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 366cd - Pipe bowls with on either side a standing lion with crown and sword, type 2. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 366abf - Pipe bowls with on either side a standing lion without crown between branches with leaves and Orange apples, type 3. Gorinchem, Jan Jansz. Blij, 1710-1720.

Leiden, Pijpenkabinet collections Pk 378ab, Pk 620b - Pipe bowl with on either side a standing lion with crown between branches with leaves and Orange apples, the mould seams bordered with pearl rows, type 4. Gorinchem, Jan Jansz. Blij, 1710-1720.

Leiden, Pijpenkabinet collections Pk 620a

- Tobacco pipe with on the bowl two shrinks or baking cracks caused by uneven drying. Gorinchem, Jan Jansz. Blij, 1710-1720.

Leiden, Pijpenkabinet collections Pk 8.945

- Various pipe bowls with in relief standing lion and lead glaze spatters. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 1.403a-i

- Misfire of nine pipe bowls backed together with brown lead glaze. Gorinchem, Jan Jansz. Blij, 1705-1720.

Leiden, Pijpenkabinet collections Pk 8.946

Notes

[1] Unfortunate non of the diggers took notice of the fragments of the saggars, hence nothing can be said about that material.

[2] Municipal Archives (GA) Gorinchem, Rechterlijk Archief (RA) 411, fol 21, 06-04-1693.

[3] GA Gorinchem, Archief Stadsbestuur (OA) 2, fol 50, 12-10-1697.

[4] GA Gorinchem, RA 349, fol 89, 14-06-1702.

[5] GA Gorinchem, Archief Hervormde Diaconie 66, fol 45, 1725.

[6] GA Gorinchem, OA 114, fol 27v, 08-09-1693. Idem, OA 117, fol 53, 27-09-1731.

[7] Don Duco, "Het assortiment van de pijpenmaker Arend van Dijk", Leiden, 1988.