The diamond pipe by Goedewaagen, a remarkable hollow bowl design

Author:

Don Duco

Original Title:

De diamantpijp van Goedewaagen, een opmerkelijk vormgegeven holwandige pijp

Publication Year:

1991

Publisher:

Pijpenkabinet Foundation

Description:

The history behind a 1930s hollow-walled tobacco pipe by Koninklijke Goedewaagen, whose design harks back to English, French and German inventions of alternative materials, including clay.

In the last part of the nineteenth century, a slip casting process was introduced in the Gouda pipe industry in addition to the traditional press technology. In this process, metal press moulds were no longer used for shaping the pipe out of tough pipe clay , but instead moulds of plaster came into use, to be filled with liquid clay. When fired this product was too fragile to be used, so the slip casted pipes have to be glazed. This method is introduced as a result of the successful production of glazed pipes from a pipe factory in the German town Grünstadt. Initially these slip cast products were imported, but soon the Gouda pipe makers aspired to make such pipes themselves.

The initiative for the change in techniques arises more or less simultaneously in two Gouda factories. The pipe manufacturer G.F. van der Want associates with G.A. Barras and starts a new factory, whose method with plaster moulds is directly copied from the mentioned German pipe factory. Their earliest products are exact copies of these German pipes. At the same time, the Firm P. Goedewaagen & Sons starts producing in plaster moulds, although they were not able to glaze well during the first years. The slip casted tobacco pipe soon became in demand. The shapes have both reminiscence of the traditional clay pipe and those made out of meerschaum and briar. The products are normally mounted with a hard rubber or wooden mouthpiece by a metal ferule. The popularity of these slip casted pipes is due to its modern appearance, but also to its absorbing qualities. During smoking the porosity of the clay absorbs the tobacco juices almost completely and the pipe quickly turns brown. This colouring becomes a popular hobby and from 1910 these cast pipes are generally sold under the name doorroker (Gouda colouring clay, or often called ‘mystery pipe’). Its success quickly overshadows the traditional pressed clay pipe.

The production process makes that the slip casted tobacco pipe has a relatively thin wall, which is a disadvantage for the smoker, since the effect is that the pipe does not always have good thermal conduction and tends to hot smoking. The liquid pipe clay is poured into the plaster mould, and the absorption of the plaster makes that the clay gets solid along the walls of the mould. Moreover, there are limitations in the design, since the outer shape line of the pipe closely follows the interior of the mould. In particularly with figural pipes with, for example, a human bust, an irregular interior is created with local spots where the tobacco burns poorly. For the smoker this means an unpleasant and - at times when thrift was the general rule - an unacceptable waste of tobacco.

Already at the beginning of the nineteenth century, workshops in Germany and France were able to overcome the disadvantage of the irregular interior of the pipe by putting a stop in the mould during casting. Around this stop, which has the inner shape of the pipe bowl, a layer of clay is deposited during casting. This method makes it possible to form the inner and outer shapes of the pipe independently of each other. The external appearance of the pipe design can therefore be purely aesthetic, while the inner bowl is adjusted to the amount of tobacco to be smoked. By consequence there is always an open space between the inner- and outer bowl. This makes it possible to realize every conceivable design, both in terms of design and bowl size.

The use of a separate stop in the mould is also known in Gouda, although it started in about 1920. In February 1922 the method of casting in a mould with stopper for the Netherlands is patented by Koninklijke Goedewaagen. In that first period of the patent, however, the designer did not fully explore the possibilities to independent development of the outer shape of the pipe. The step to a truly free pipe design, no longer based on the traditional clay pipe and the briar shape, only emerges ten years later. The reason for this lies in the lack of interest by the Gouda pipe manufacturer to come to a truly innovative pipe design, which is obviously related to the status of their product and their customers. Feeling for design did not live in the factory, nor among the target group, the average smoker.

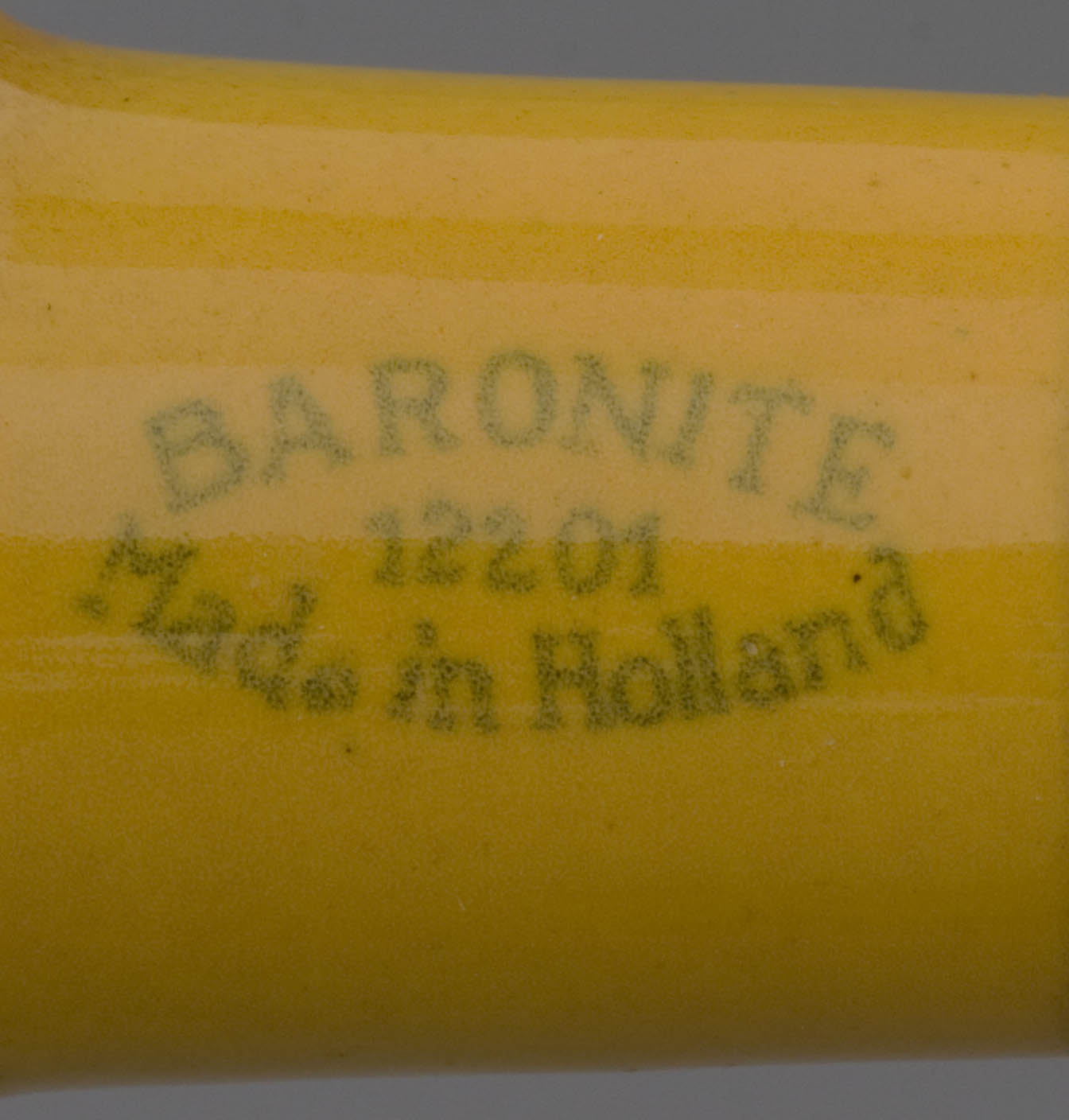

In this article I would like to discuss one of the first shapes of slip casted pipes that show a free design line. It concerns a hollow walled pipe bowl known as diamantpijp (diamond pipe). This model was registered in the book of pipe shapes of Koninklijke Goedewaagen under number 837 and was created in the year 1934 (Fig. 1). The registration mentions “Baronite met steel in het midden, het model heeft deukjes“ (Baronite with stem in the centre, the shape has dents). In those years Koninklijke Goedewaagen used the word Baronite generally to indicate the hollow bowl system. The products of the competing company P.J. van der Want Azn., which introduces this system simultaneously but did not patent it, are called Wanta pipe, a play on the company’s name and the hollow wall, in Dutch wand of the pipe bowl. The older Goedewaagen designation, namely duplex, is a more understandable word for the double-walled system, but this designation was never introduced onto the market. The Goedewaagen modelling book mentions the word duplex only with the earliest pipes, but this word is later crossed out and renamed baronite.

The bowl line of the diamond pipe is remarkable and tends to an egg shape. The bottom is round and the stem is attached halfway the bowl. The facetted exterior of the bowl makes the product playful while the separate mouthpiece ensures maximum user comfort. The connection between the ceramic and the mouthpiece is marked with a gilded metal band around the stem stamped with the factory name as a trademark. The mouthpiece is imitation amber with a yellowish marbled hue, a type of plastic that is colourfast, wear-resistant and neutral in taste. The mouthpiece is clamped in the ceramic stem opening with a cork insert. This flexible cork connection gives sufficient strength but makes the mouthpiece easily removable, so that the pipe can be cleaned when necessary.

Finally, the colour of the pipe is interesting. The bowl has been sprayed orange-yellow, while the opening has a brown-etched zone, which should indicates an already smoked pipe. This colour refers to calcined meerschaum pipes, which are boiled in hot oil and subsequently roasted dark around the bowl opening. From 1880 onwards, calcined pipes are the counterpart of the ivory white meerschaum pipe. At the time they mainly anticipate the popular -and cheaper- imitation pressed meerschaum pipe, the material which does not colour and therefore usually was pre-coloured to look as if it had been smoked for a long time. At that time a well-smoked pipe was a status for pleasant and tasty smoking.

With the diamond pipe, Goedewaagen therefore aimed to combine the positive qualities of the lightweight baronite with the luxurious appearance of the meerschaum pipe, while also combining the hygiene of the older, so-called “health pipe”. It is therefore not surprising that the diamond pipe belonged to the more original and luxurious items. Nevertheless, the aspect new to this product was insufficient, because it is clear that this pipe design shows relations with various previous inventions.

A similar design of a hollow-walled pipe bowl with a stem half way the bowl, is the so-called gezondheidspijp, literally "health pipe" (Fig. 2). This is a pipe with an undecorated bowl in the shape of an egg. Again the stem is not connected at the bottom of the bowl, but halfway the height. This design offers a practical advantage: the condensation released during the smoking precipitates in the space between the bowl, but cannot enter the stem. For this reason the pipe always ensures cool and dry smoke. The gezondheidspijp perfectly meets the requirements of hygiene and clean smoking of the pipe in those days. The inner boiler is cast separately from the outer bowl and is clamped with a cork ring. This allows the smoker to thoroughly clean the space between the inner and the outer bowl. The disadvantage might be that the cork edge could start leaking.

In the category of health pipes we do not only charge products with space between the bowl and the stem where the moisture released by smoking can settle. Other examples include an absorbent nicotine stone at the bottom of the pipe bowl that provides the desired drainage. All these efforts to dryer smoking come with the introduction of tobacco to which aromatic substances were added, which increases the moisture of the smoke and thus requires a dryer smoking pipe. The introduction of the so-called gezondheidspijp started in the 1870s, both in England and France, although such pipe shapes were also made in Austria and Germany, in clay, ceramics and block and pressed meerschaum, respectively.

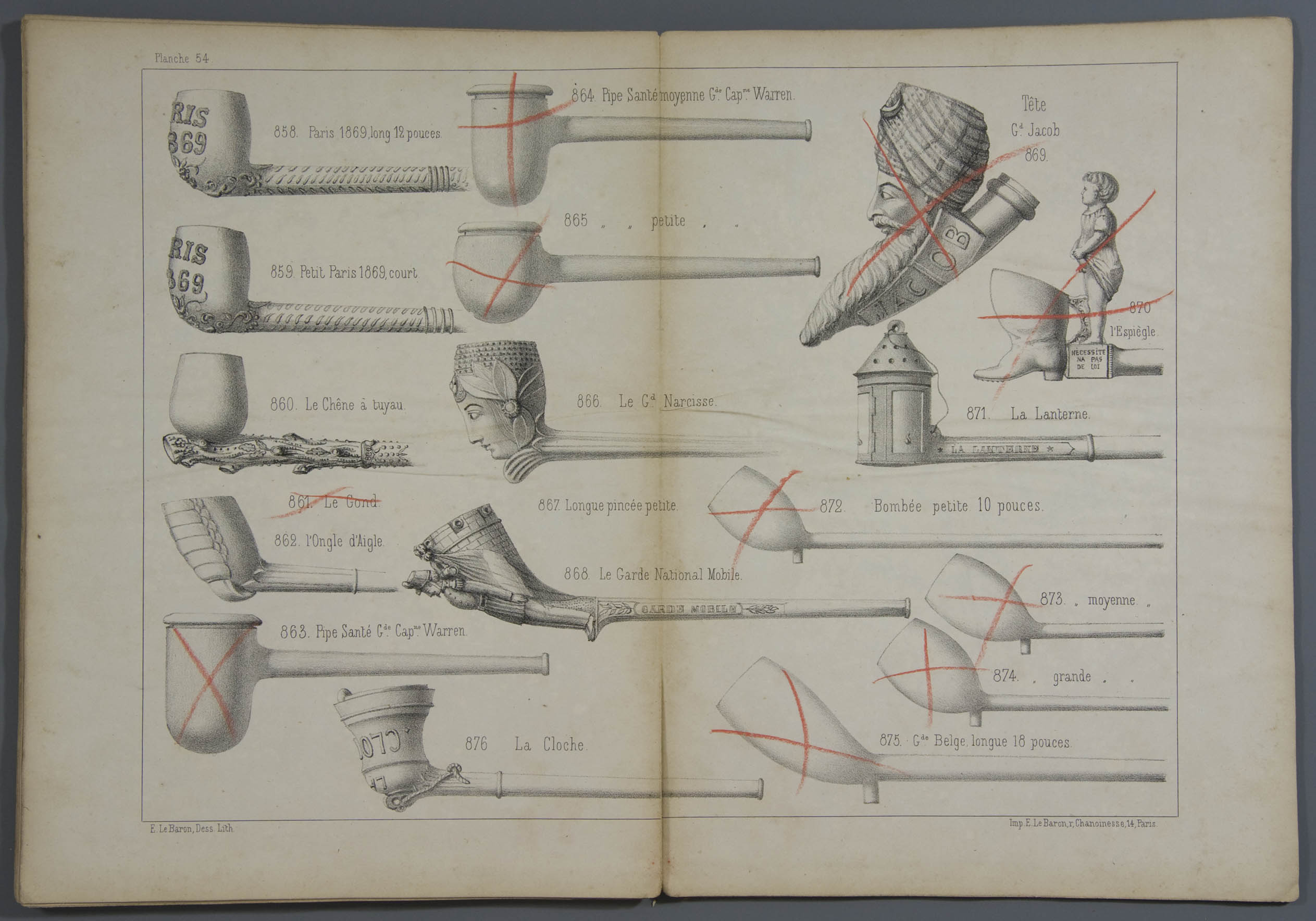

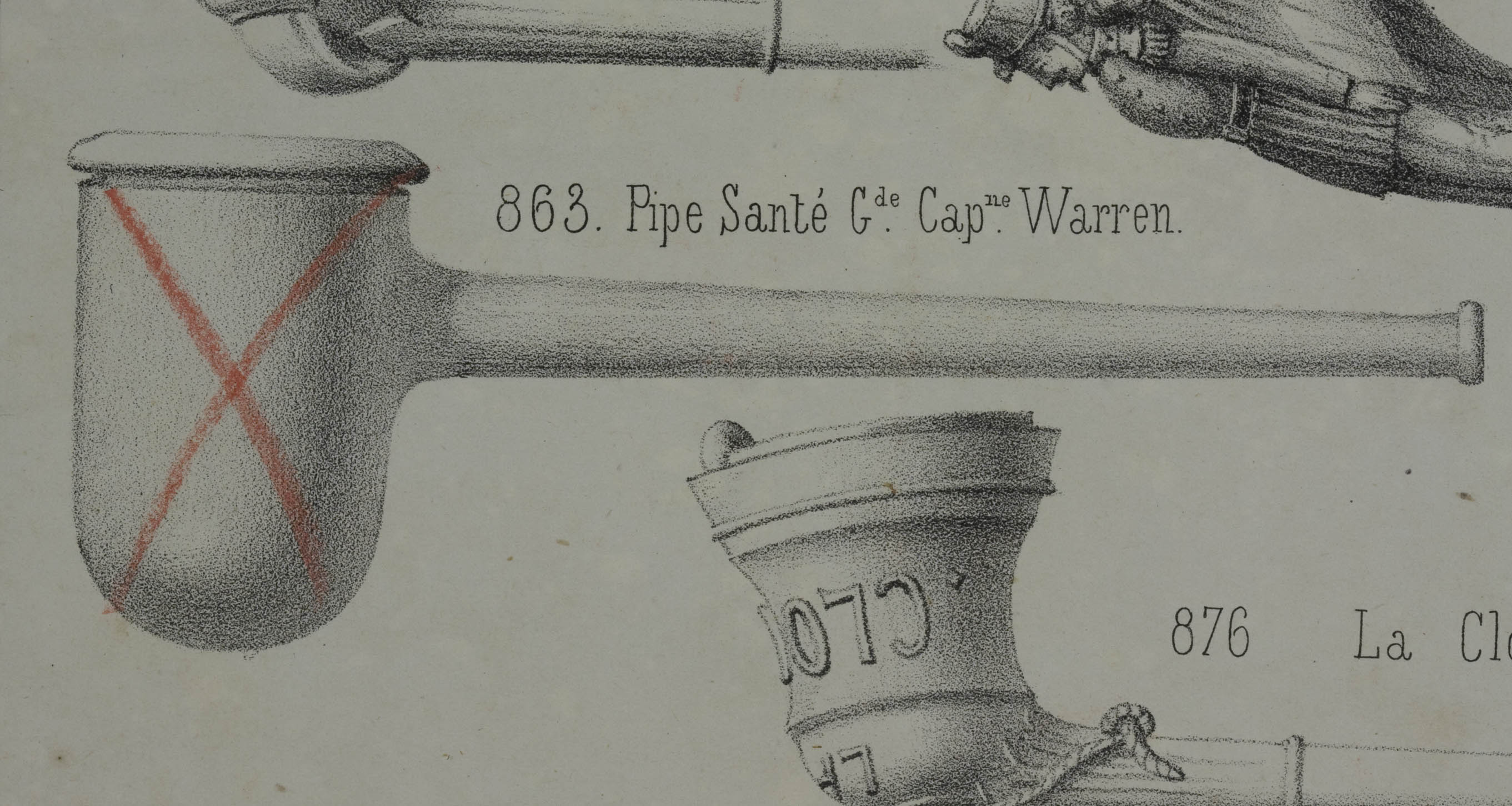

A similar health pipe can be found in the factory catalogue of Gisclon in Lille (Fig. 3). This well-developed pipe factory offers a wide range of traditional pressed clay pipes. Three models however are derived from the gezondheidspijp and were designed in or shortly before the year1870. Model 863 and 864 with a slim bowl in two sizes and model 865 with a small oval almost convex pipe bowl. The stem of these pipes is entirely made of clay. The description mentions "Pipe Santé Capne. Warren" with the addition of the format: "Gde." for large, "Moyenne gde" for middle and "Petite" for the smallest version. Captain Warren most likely refers to the English archaeologist Charles Warren, who carried out excavations in Jerusalem during that period. Whether he became known by smoking hygienic pipes is still a question, just as we know nothing about the technical details of the Gisclon pipe that has never been recovered until today.

Coincidentally or not, our diamond pipe also has a relation with the well-known corncob pipe that was made by large numbers since 1870 in America. This pipe is turned out of the maize wood of the corncob, a waste product that was massively available. The positive properties include the minimum purchase price and the light weight. The absorbent effect of the maize wood also ensures dry smoke, while the aftertaste is slightly sweet and therefore pleasant. Due to the soft maize wood, however, corncob pipes are vulnerable and burn quickly. This is why this species does not have a long life and is by many smokers considered as a disposable pipe.

Even within the Koninklijke Goedewaagen the diamond pipe is not entirely in itself. Remarkably enough, among the gypsum designs by Goedewaagen, there is a smooth baronite pipe that shows strong similarity to the Warren pipe from Gisclon (Fig. 4). The model number "895" was written in ink on the plaster and later faded away. As far as we know, this shape has never been produced; a tobacco pipe is not known. The reason for this is probably that this remarkable model fell between two styles. It was not a traditional shape that met the expectations of the classic smoker. On the other hand, as a design it was not special enough to score among trendy fashion-conscious smokers. Unfortunately, it is unclear whether this design is older or more recent than the diamond pipe. The higher shape number presupposes the latter, but the restrained design pleas for the first. It is certain that the model numbers at Goedewaagen have not always been assigned in chronological order.

In its time, the diamond pipe has been a special product. In the 1930s, the Dutch pipe smoker is no longer a fashionable appearance, eager for the latest fashion accessories. Pipe smoking has gone down to the class of older, often conservative smokers with a small purse. The cigarette then represents the sophisticated smoking. An exuberant pipe design l had therefore little chance of success. That also seems to have been the case with this pipe. It is therefore not surprising that the manufacturer has made only limited use of the baronite pipe's ability to allow free design. The market was unsuitable for achieving economically profitable designs. Combining properties of three existing popular pipes in a new product is a safe attempt to create new sales among a more progressive smoker. The introduction of such a new design could bring about a revolution among smokers, but it was more likely that it would be a flop. And the latter has been the case. Sales figures are not known, but the circulation has certainly not been great.

In fact, the diamond pipe is a combination of several nineteenth century ideas about cool, dry and hygienic smoking, expressed in a Gouda way and materialized within the limited possibilities of the interwar period. Innovative to the pipe is only the exterior design of the product, the "dented model". The renewal in design is special and at the same time a one-of-a-kind statement, unfortunately not followed by a wider movement. However, maybe not even unique, since it is not inconceivable that this surface treatment already existed at the meerschaum pipe. How a successful new design will grow into a kind of fashion can be noticed in the comparison with another merit from the same year. In 1934 Royal Goedewaagen also introduced a series of B.M. pipes, modern products having the same baronite system. Now, however, a really modern design is created, the so-called streamline. These products were the subject of the advertising campaigns conducted by Goedewaagen, while the diamond pipe was advertised only by the retailer. Due to the limited interest, this product disappeared from the market after a few years and that is why this wondrous pipe is now one of the rarities.

© Don Duco, Pijpenkabinet Foundation, Leiden - the Netherlands, 1991.

Illustrations

- Tobacco pipe, slip casted with hollow bowl system, facetted oval bowl, stem connection at the middle of the bowl, metal ferrule stamped "GOEDEWAAGEN HOLLAND", mounted with imitation amber mouthpiece. The Netherlands, Gouda, Koninklijke Goedewaagen, shape number 837, 1934-1936.

Leiden, Pijpenkabinet collections Pk 5.968

- Tobacco pipe, slip casted with hollow bowl system, plain oval bowl with separate inner bowl with brown rim, stem connected above the middle and up going, metal ferrule stamped with "REGAL" and original black vulcanite mouthpiece. Belgium?, 1880-1910.

Leiden, Pijpenkabinet collections Pk 9.749

- Page from the catalogue of Gisclon, Lille illustrating the gezondheidspijp, health pipe with separate inner bowl and straight stem of clay. Shape date circa 1869-1870. Including detail of the page with the most common shape. Lille, catalogue by Firm Gisclon, circa 1875.

Leiden, Pijpenkabinet collections Pk 726 - Model in plaster of the gezondheidspijp with cylindrical bowl and round base, stem attached at the middle of the bowl. Bowl on the left in ink shape number "895". Gouda, Koninklijke Goedewaagen, 1925-1935.

Leiden, Pijpenkabinet collections Pk 11.895

- Model in plaster of the diamond pipe with egg shaped bowl facetted on all sides, stem attached at the middle of the bowl. Bowl on the left in pale ink shape number "837". Gouda, Koninklijke Goedewaagen, 1925-1935.

Leiden, Pijpenkabinet collections Pk 11.837