Mouldmakers' tools from Courtrai, Belgium, a discovery of great value

Auteur:

Don Duco

Original Title:

Vormmakersgereedschap uit Kortrijk, een vondst van onschatbare waarde

Année de publication:

1991

Éditeur:

Pijpenkabinet Foundation

Description :

About the purchase of tools from the mould makers workshop of the pipe factory De Bevere in Kortrijk and the history behind this unique material. The article reveals important information about the techniques of the press mould makers that seemed to be lost.

From pipe factories of various West European centres quite a number of brass and iron press moulds have been preserved. That is understandable because the press mould, being the main production tool, was an expensive implement, normally handled with care. When a company ended production their moulds were the first utensils to be sold to a colleague. If there was no interest locally, it was always possible to look for candidates in other production centres. So tools were transferred from one factory to another and even travelled around the country and beyond, till they were worn off and ended in the melting pot.

Quite a difference with all the small tools that were used together with the press mould. Especially objects such as weijers, botters, mark stamps and more got lost because of their small intrinsic value. They were simply replaced by new ones when the press mould was put into production again. The same fate underwent the mould makers tools, of which each company owned some pieces. They were used daily in the larger workshops to keep the press moulds in good condition. Nevertheless these tools are barely preserved in other production centres, not even in a major pipe making city as Gouda.

We can therefore conclude that it is a unique opportunity to purchase an impressive collection of mould making tools at a former pipe maker in the Belgian town of Andenne along the river Meuse.[1] In 1985, six crates emerged from the shed of this manufacturer and merchant at Avenue Roi Albert, containing tools that were used for mould making and stayed unpacked for nearly forty years. At the moment of discovery, these tools were still packed in completely corroded crates of the emergency food that the Canadians had brought during the liberation of the Second World War. The importance of this collection is that the tools provide a lot of new information about the maintenance of the press moulds. That knowledge is the subject of this article.

The origin

The last owner and selling party was Jean Dernoncourt, since 1958 retired pipe manufacturer, and until that time owner of the Emile Levêque pipe factory. Dernoncourt had purchased these tools in 1947. The origin however is not Andenne nor the adjacent Andenelle, but a pipe factory from Courtrai (Kortrijk). The vendor there was the last director and owner of the factory De Bevere, who had decided to liquidate his company after the Second World War.

In their successful years the De Bevere factory was widely renowned. [2] According to say, the workshop would have been founded around the year 1800, which is about right since the first archival entry dates from 1819.[3] The management of the business goes from father to son and a century later came into the hands of Amand Charles de Bevere. This last director was born in Kortrijk in 1886 and died in 1952 in De Panne, at the Belgian coast. From a small workshop this company grew into a real factory with a large production. That movement started in the second half of the nineteenth century.

Even after the year 1900, the company continued to expand, for instance a new factory façade was built. In the thirties the sales of the product decreased and the factory was forced to slender down. The company did not do well during the period of the Second World War either, Courtrai being very close to the heavy battles along the trenches. After the war director Amand decided to close down. He approached pension and no longer saw a future in the pipe industry. Gradually the company is sold out and one of the candidates is the mentioned entrepreneur Jean Dernoncourt.

The post-war period is not an easy period for the sale of production material for clay pipes because of the steady decreasing demand. The pipe industry had lost sales for decades to such an extend that in the area where De Bevere was active, the two factories of Scouflaire and Croquet Michel had already disappeared. In the region itself, only a few small independent pipe makers survived. In these small workshops however, there was no money nor interest for investments. So it came as no surprise that Dernoncourt presented himself as an interested party. In 1945 he had taken over the factory from Emile Levêque and since continued working in the Rue des Chats. At that time, it was the only really active pipe factory in Andenne.

Jean Dernoncourt was a seasoned businessman and knew about negotiating. He has an interest in the inventory for two reasons. Firstly, he acquired additional production material for his own pipe factory, in order to produce also pipes in the style of the West-Belgian pipe makers. In addition, as a buyer he could resell redundant tools, while he himself is in control to whom. In this way he deprives his competitors of the opportunity to benefit from this liquidation, while the profit flows into his own pocket. Certainly, it was beneficial to the negotiations that the factory buildings had to be cleared in due course. So, there was every reason to transfer as much material as possible to Andenne by train.

At the purchase, Dernoncourt has a special interest in De Bevere's well-developed design studio and workshop for tool maintenance. This department was set up by the father of Amand and was mainly focused on the specific design of the clay pipes popular in the region. The West-Flandres region along the Belgian-French border, with towns as Courtrai, Onnaing and Maisières, was most important for pipe production in this part of the country. In contrast to the pipes produced in Andenne, in the eastern Walloon region , the Courtrai pipes were tighter in design. The specialized tools from the De Bevere design workshop could guarantee this specific style.

Amand de Bevere's father knew the requirements the local smoker imposed to the clay pipe in terms of shape and quality. Thanks to his keen sense of technology he initiated an impressive department where roughly founded press moulds could be finished to smoothly polished moulds exactly so to meet with a specific demand, complete with the pinhole connections. This workshop also did the maintenance of the tools, which meant keeping the mould in good shape by filing away all wear marks using the appropriate tools. Only that method guaranteed the desired pure shape of the clay pipe.

The tool themselves

The wooden transport boxes that were filled for Dernoncourt contained about 400 steel chisels, gouges and files, and another hundred other hand tools. At De Bevere, this material was neatly arranged in racks above the workbenches in the moulding department and was actively used there until the factory closed down. From this location it was carefully packed in the mentioned wood boxes waiting for a new life (Fig. 1).

Taking a closer look to the utensils, it is striking that for each aspect of shaping a set of six to twelve and sometimes even more special size-varying tools had been made. This made it possible to treat every press mould with maximum accuracy, regardless of its size. In addition, the tool matched closely with the highly standardized shaping of the De Bevere pipes that, as noted, are characterized by a very specific, almost mechanical design. This in great contrast to the pipes from Andenne where the technical knowledge was at a significantly lower level, so the design was less tight.

The first form of perfection is expressed in the uniformity in the handles. Because these handles differ per set, we can discover a certain development. The earliest specimens are completely cylindrical and sometimes have one or a few turned ornamental rings (Fig. 2). This method was still customary in the nineteenth century but later disappeared. The head end resting in the palm initially shows hardly any rounding. Only after the year 1900 the ends are rounded off (Fig. 3). The other end, where the steel tool is attached, is always provided with a metal band by way of reinforcement.

Only well into the twentieth century a more ergonomic handle comes into use, which is made of a lighter wood type with a waved and bulging outline. Then the end becomes also more comfortably rounded. In some cases, the handle is additionally reinforced at the end with a steel wire band around the wood as a protection against splitting (Fig. 4). Because hard woods were used for the handles, they are perfectly preserved and not affected by the woodworm. This in contrast to the packaging crates that were completely eaten and mouldy in some places.

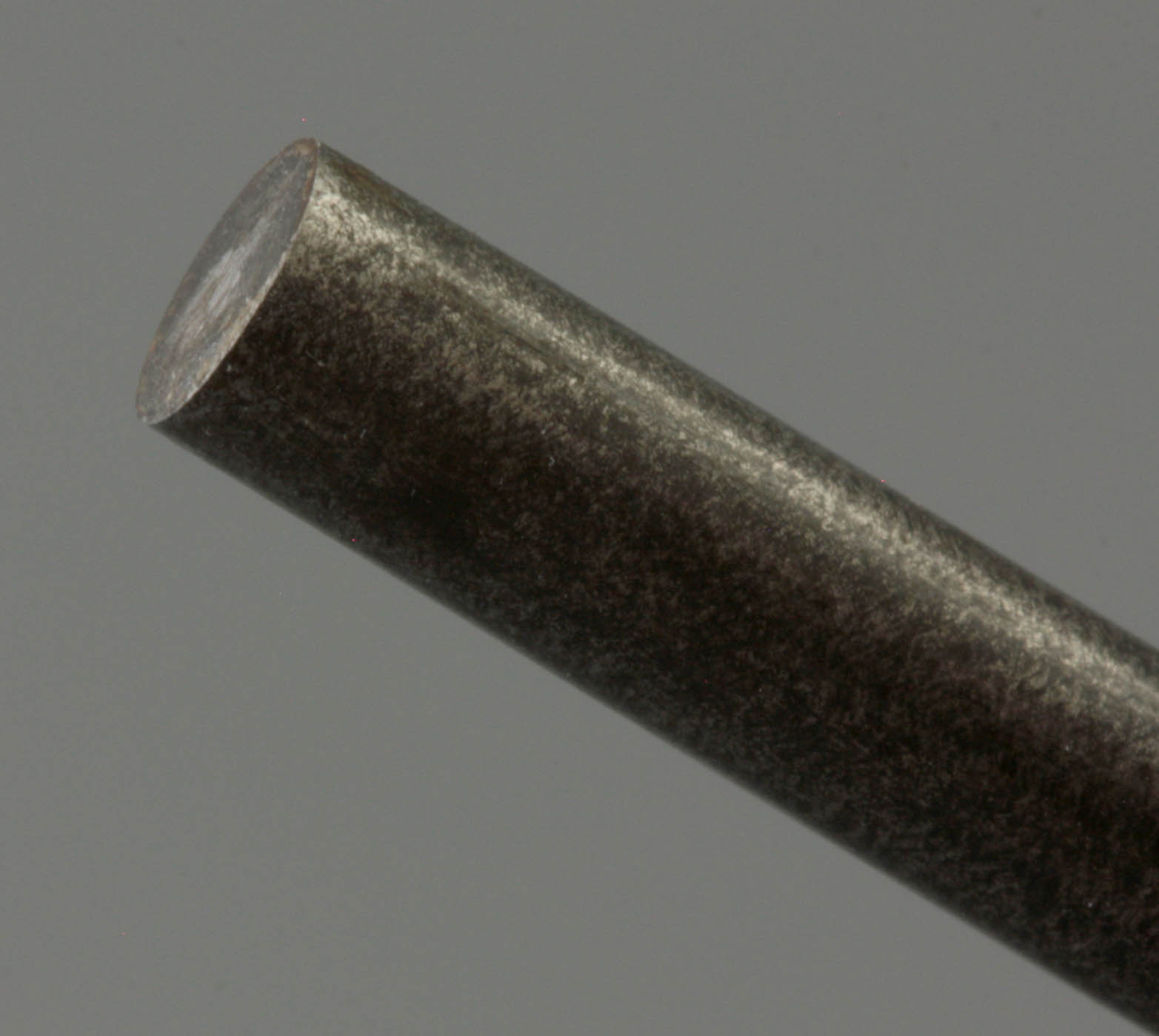

The different types of instruments certainly deserve an individual inspection. Each series served a special purpose, which makes us understand the various actions needed for finishing a press mould. For the first treatment of the rough mould half, very simple metal chisels were used (Fig. 5): a straight, cylindrical rod of steel, perfectly straight cut at the end. It is precisely with that sharp right-angled edge that it is possible to stick a curl of metal out of the stem of a metal press mould. These steel chisels served to bring the stem of a rough casting to the correct diameter. In addition to round metal chisels, there are also specimens with an oval diameter that are used when the pipe stem has to be slightly flattened. Depending on how he holds the tool, the mould maker produces a wider or deeper stem.

After the stem has been roughly adjusted to deepness and diameter with the metal chisel, the next tool is the stem scraper (Fig. 6). This is a solid cylinder shape provided with concentric constricted rings of which the outer edges are razor-sharp. In contrast to the metal chisel that makes curls, this instrument gives off flakes of metal. As an after-treatment, an ordinary file is used (Fig. 7), which is roughened like any file so that it pulverizes the metal and produces fine copper cross. As to be expected this tool is also available in various diameters.

For the bowl of the pipe similar instruments are used, also available in increasing sizes. For the perfect design of the bowl, less work is executed with chisels and scrapers, but more with files. The reason is that evenly flattening a larger surface to get a perfectly rounded shape requires finer instruments. For global shaping, so-called reamers are used (Fig. 8). They exist in a chisel and in a rasp version. The chisel versions are facetted, usually octagonal. The rasp variant is longitudinally divided into panels, alternately smooth and grooved. Both instruments have no handle but are used with a crank.

When the bowl has been brought to the right diameter, finishing is the final step. For this work various types of oval-shaped files are in use (Figs. 9-10). A later version has a globular shape but serves for the same work (Fig. 11). To finish the top of the pipe bowl well, very specific tools have been devised. This zone, which is called in Holland directie, shows a narrowing in the press mould in order to better guide the stopper so that it descends in the correct position in the bowl and guarantees that it is maximally centred; in other words, this part helps in directing the stopper . Between the pipe bowl and the zone for the stopper a sharp edge is needed, so that the place to cut off the crown of the pipe is clearly marked. Special sickle-shaped files are used for this purpose, in Gouda they are called directie vijlen (Fig. 12).

Many of the Flemish pipes have a heel between bowl and stem for which a separate file has been designed: it has a special bent going over the mould box in order to descend undisturbed into the heel. These implements come in a range in sizes (Fig. 13), even while special files for different heel shapes like button heels. The same is the case with the button nozzle, for which an special type of file has been devised (Fig. 14). The main part of this instrument has the diameter of the stem, while there is a thinner part after the knob nozzle to keep that location in the mould narrow that guides the metal wire in order to prevent the clay from being pressed out of the mould. Proof of the incredible extend of the array of files in the mould makers workshop is the fact that there is even a file for a giant button nozzle for a presentation pipe!

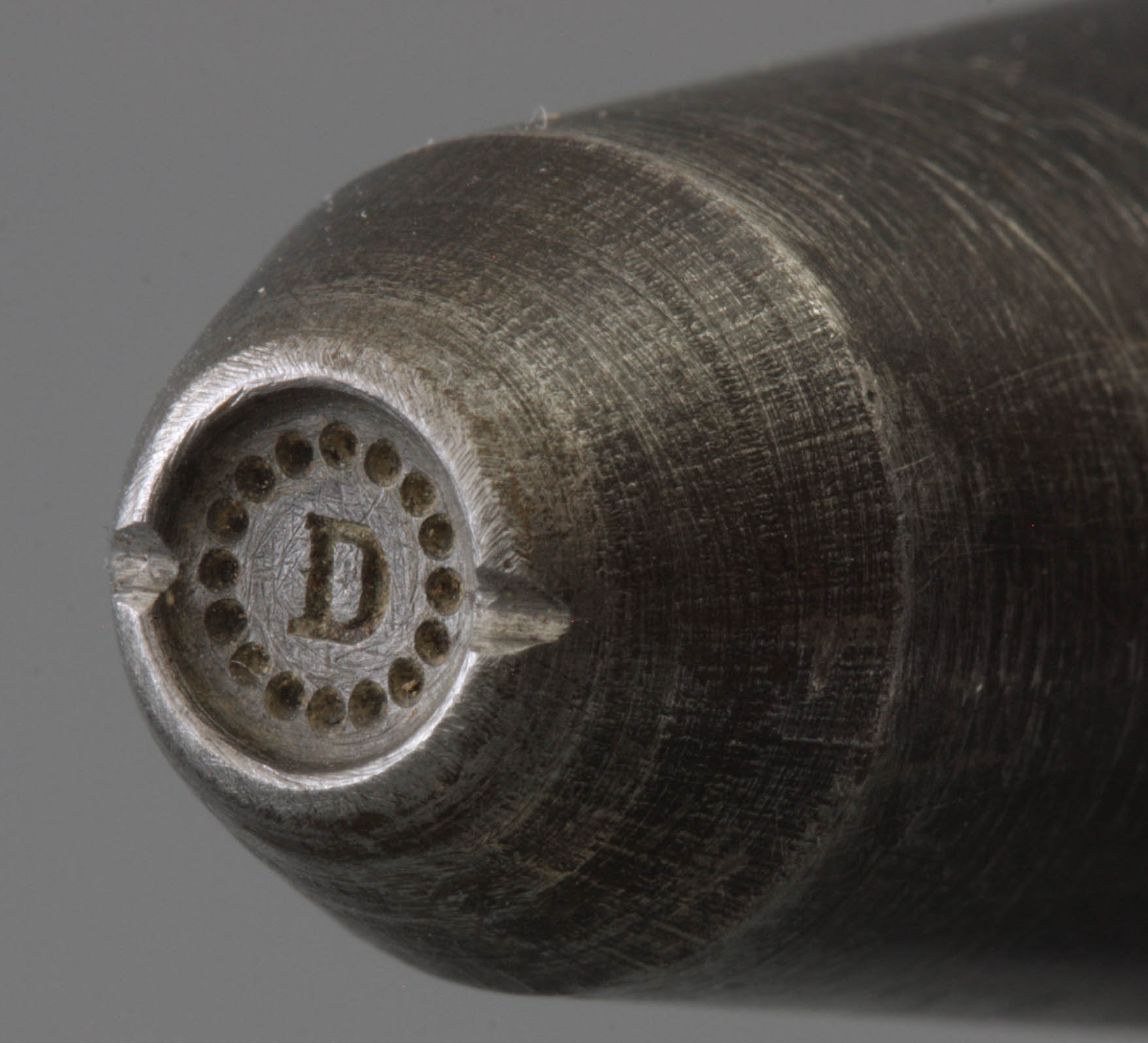

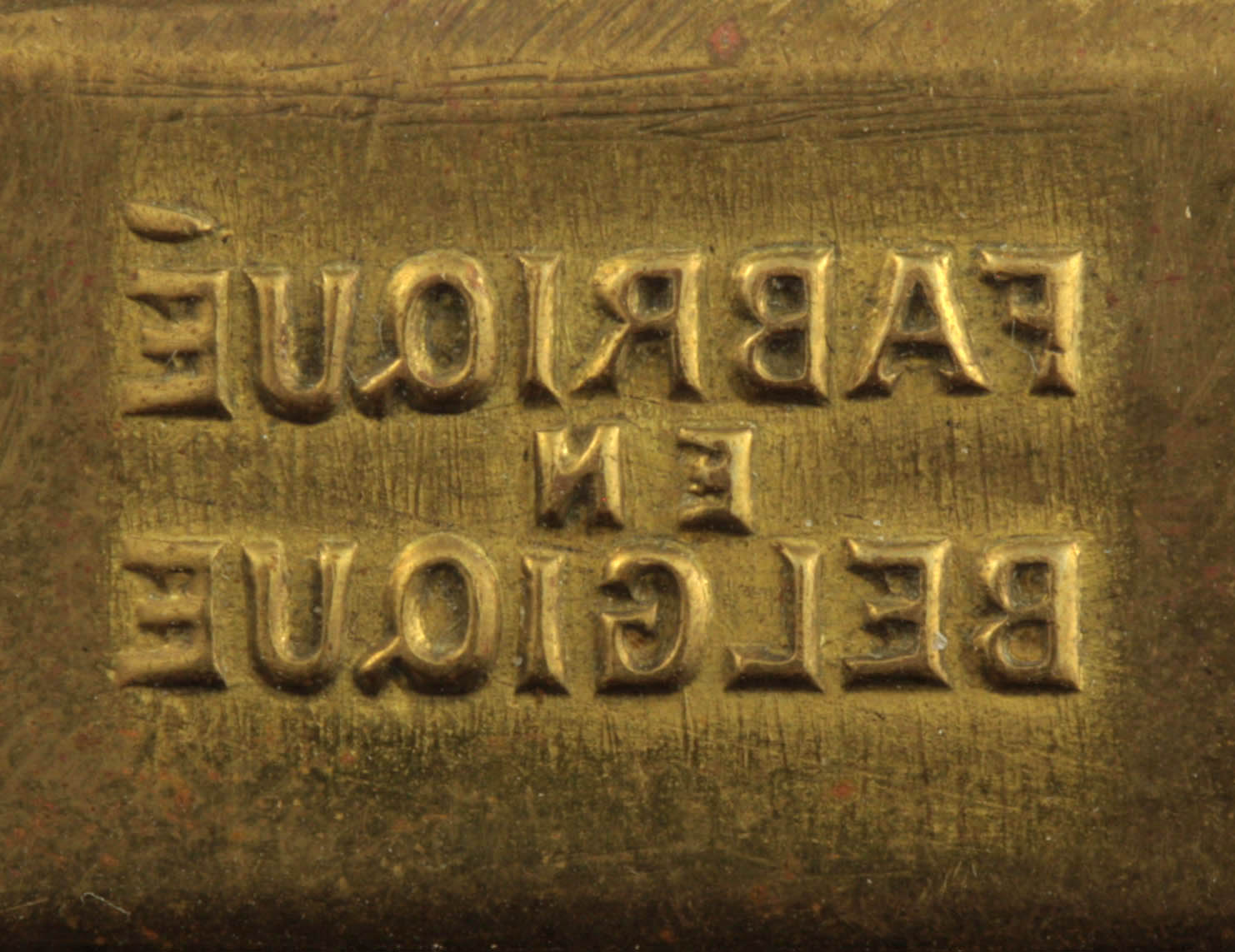

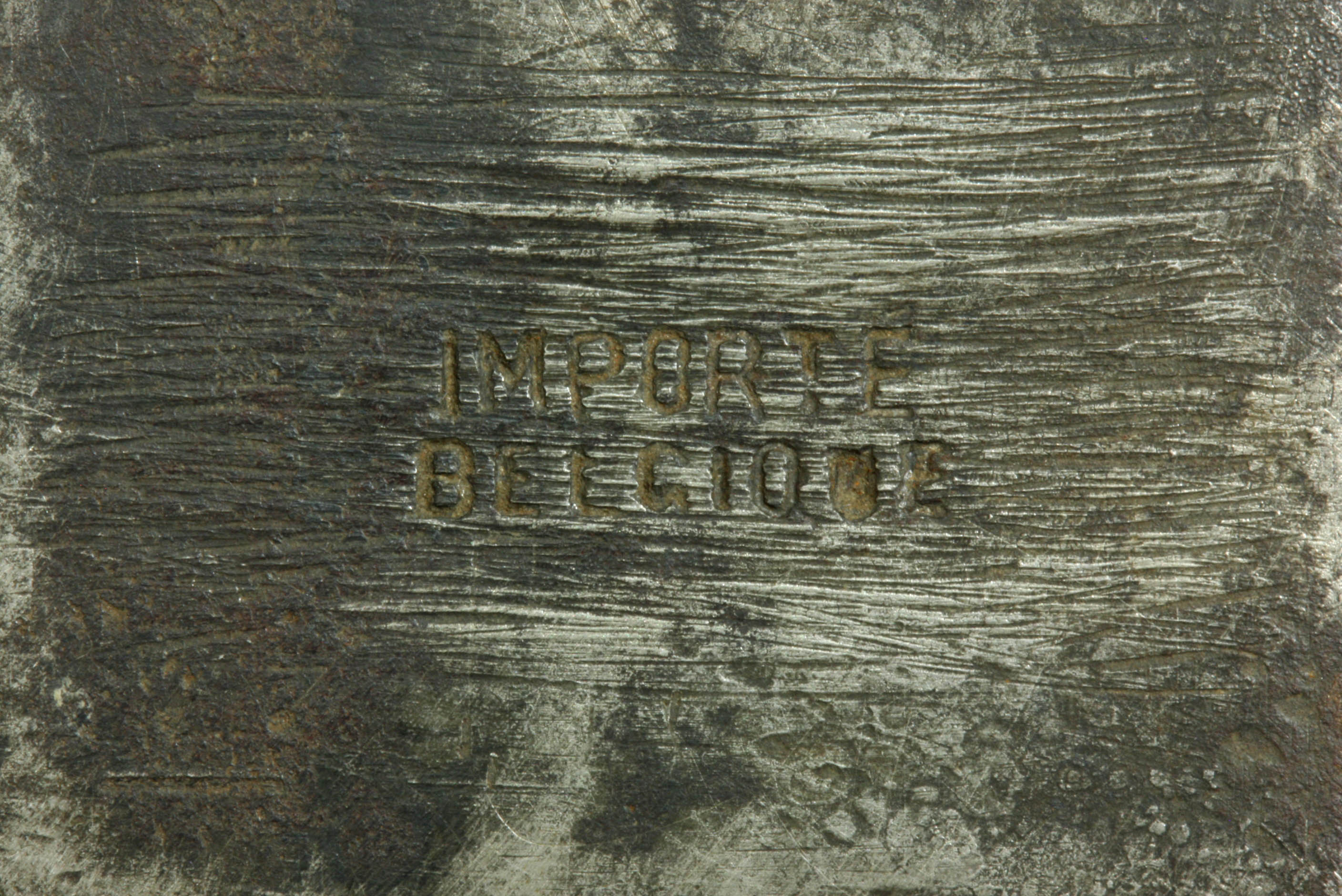

The workshop for moulds did not only serve to prepare and maintain the press moulds. The other tools were also made here. The stoppers for pressing the inside of the bowls were, after being moulded, grinded to the correct length and diameter. Furthermore, there were the steel moulds for the brand stamps and the brand plates (Figs. 15-18). The De Bevere company marked their pipes with a heel stamp initial D (Fig. 15, 16). On the pipe stem this was completed with the text intaglio DE BEVERE KORTRIJK, later replaced by FABRIQUE EN BELGIQUE (Fig. 17, 18).

Comparable tools

Of course, other pipe makers possessed mould maker tools too. Often this is limited to a set of simple utensils to do the preliminary maintenance of the press moulds. In addition, some factories had their own workshop where the raw castings can be finished into a useful press mould with a shiny smooth shape as the final result.

The technique to finish and maintain tools must have been about the same everywhere. That some industrial espionage had brought uniformity in the tools has been proven. This is evidenced, for example, by the fact that every generation of directors of P. Goedewaagen & Sons learned to make moulds in the Liège area. The technique of creating and maintaining the press moulds was therefore supra-regional, although there were undoubtedly local customs and techniques and certainly regional variations.

In the company inventory of P. Goedewaagen & Sons from 1918 we find a description of the moulds including a series of mould making tools.[4] Although brief, this inventory is important to gain an insight into what gear was present in Gouda during the same period. In the list we find 41 different names, many of which refer to implements that were apparently used in different sizes next to each other. Unfortunately, the tools of that workshop have not been preserved. When this material was no longer used after the Second World War, the department was shut down and the tools disappeared without destination.

At Goedewaagen, the workshop of the mould maker was next to the mould loft, the storage where the press moulds were kept. The workshop itself was relatively small with a workbench with both a vice and a lathe. Furthermore, we find a stool and a cupboard. Along the workbench we find the usual tools such as wooden and iron hammers, two hand drills with series of drills and all kinds of other tools. A ball grating is available for measuring, but also a round compass and a spring pass. More interesting are the small tools specifically designed for the mould maker which are unfortunately rather cryptically described.

It is a challenge to link the names in the enumeration in the Goedewaagen inventory to the tools of Dernoncourt c.q. De Bevere. That is not easy because we do understand very little of the names of the tools written down. Nevertheless, some items can be understood. For kopstrokers (see Fig. 9) and pissebedden (see Fig. 10) we can think of bowl files with a certain shape, suitable for giving the oval bowl its volume and keeping it in that shape. We see schenkvijlen (literally stem files) for the maintenance of the stems. With opdrijvertjes, chisels are probably meant to hit the brass from one place to another, in particular along the worn mould seams so that they will better close. A directiehamer (direction hammer) was used to secure the steering pins in the crown of the mould. There are also numerous tools such as a rattenstaart (litt. tail of a rat) and other files that do not have a specific purpose.

Particular for Gouda are the numerous dies used for the makers’ mark as well as for texts in relief, and more specific a die with the city coat of arms . It is clear, however, that in a large company such as Goedewaagen the mould makers tools are only a fraction compared to those of the De Bevere factory. This fits in with the image we have of both companies. De Bevere designs his own pipe shapes and makes his own press moulds, while Goedewaagen buys old-fashioned press moulds elsewhere and therefore has more of a repair shop than a workspace for new tools.

Reuse in Andenne

The inventory of the De Bevere mould makers workshop did not get a second life. For unknown reason the boxes in which the tools were transported from Courtrai to Andenne remained unpacked in the shed of Dernoncourt until October 1985. It could be due to the technical quality of the material. In fact, the tools were too specific and too numerous to serve in the pipe factory in the Meuse region. The pipe makers in the Belgian river Meuse area did not set such high standard as the customers in the region of Courtrai, where highly industrialized products were made. This particular West-Flemish design did not fit in the Meuse region where the industry was more easy going, less standardized resulting in a less uniform, more crafted product.

The wish of Dernoncourt to make the style of the De Bevere pipe in Andenne was not implemented either.[5] The reason is that finishing and especially the careful burnishing of the pipes was not done in Andenne anymore. That habit had disappeared partly because the Andenne clay was less suitable for this. The simple way of preparing the clay did not result in the desired shiny texture. Moreover, the smooth polishing of the pipes demanded great professional competence, a high-priced work that was absolutely unprofitable in the years after the Second World War. A third reason was that the De Bevere factory finally did not close down, the production downsized and was continued by the brother-in-law of the last director. In the region around Kortrijk, this new company remained an important supplier of clay pipes and for Dernoncourt an unexpected competitor.

Undoubtedly Dernoncourt had hoped that he could continue the production of the typical shapes from the western Belgian-French border region with the tools of De Bevere. For that reason, he had even purchased a series of press moulds from De Bevere. In the end, this specific Flemish taste did not get off the ground in the Rue des Chats, with two exceptions. Out of the popular press moulds with the horse, a stub stemmed bowl from De Bevere, pipes were produced until 1958. Also large quantities of a stub stemmed bowl with bird claw were made. In the end, also for Dernoncourt the business dried up slowly until it was inevitable that the factory would close down.

We can therefore rightly wonder whether the purchase of Dernoncourt has been successful. Both the re-use in own company and the sale to others were not implemented. Although Dernoncourt might have assigned himself the role of reseller and dreamed of attractive profits, that never happened. Certainly he would not have suspected that an important part of this material would remain unused for decades, finally to bring in a reasonable financial revenue during his old days. At that moment the use value was transformed into a curiosity and museum value.

Conclusion

Now that we know about the existence of the mould makers tools from De Bevere, this provides us a completely new perspective on the manufacture and maintenance of press moulds. Unexpectedly we meet with a tool collection that is great in sizes and large in variety with almost all instruments available in multiple diameters . In addition, we can be amazed about the extraordinary great perfection of all the tools and not in the least about the care and prudence with which everything was made. It is clear that this material radiates an incredible love for the technique.

By taking a chisel or scraper through a press mould, one can experience the importance of excellent tools in finishing a rough press mould or sharpening a used one. Performing this task, subsequently handling the chisel, the scraper to finish with the file, it takes hardly any effort to work the metal. Although it obviously remains a meticulous job that requires a lot of skill and precision, working in this way is no longer an insurmountable obstacle. Knowing these tools explains the fact that a mould maker can finish a rough castling within a day and a half into a perfectly locked press mould. It also explains that sharpening a press mould can be done in an hour.

However, it is questionable whether this technical hobby of the second last director of the De Bevere factory was also the hobby of other pipe manufacturers. No doubt that a wide range of appropriate tools makes the mould maker’s craft exceptionally pleasant, but the time investment in such a set of tools was considerable. The forging and tempering of the various iron instruments was a profession in itself and only years of production justifies building up a specialized workshop like this.

For sure De Bevere possessed one of the best-equipped and most streamlined mould makers workshops in Europe. Another special feature is that the tools show the specific style demonstrated in the West-Belgian pipe. At the largest Gouda factory, Goedewaagen, the emphasis of the mould makers tools was on sharpening, patching up and keeping the press moulds in working condition. At another factory such as Gambier in Givet, the focus was on shaping highly decorated products. In Kortrijk, it is only about getting a perfectly functioning pipe moulds within the predetermined design principles. At a factory of roughly twenty workers, about fifteen sharpening or adjustment sessions on the moulds were performed every week. In addition, an average of two new press moulds were made each month. The mould maker tools were actively used.

Obviously, we regret that we do not have any photos of the original workshop. Then we could see what the workbenches looked like and would be able to get a better image of the way this department functioned. Now, the exact succession of handlings and the function of certain tools are still shadowy. In addition to these well-thought-out tools, De Bevere's design department will have had a streamlined way of working with an efficiency we would not have conceived before the lucky discovery of these tools. We owe this piece of insight to the acquisition of Dernoncourt and the fact that he never found any use nor client for this unique set of tools.

© Don Duco, Pijpenkabinet Foundation, Leiden – the Netherlands, 1991.

Illustrations

- Display of the mould makers' tools of De Bevere in the Pijpenkabinet museum in Leiden, including some items separately photographed. Belgium, Courtrai, De Bevere firm, 1860-1900.

Leiden, Pijpenkabinet collection Pk 8.896-8.910

- Handle of the oldest type with cylindrical body and ring. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 8.898a

- Handle of later date with larger body but in lighter wood. Courtrai, De Bevere, 1900-1920.

Leiden, Pijpenkabinet collections Pk 8.907a

- Handle of the more modern type partly with reinforcement of steel wire to make it stronger. Courtrai, De Bevere, 1910-1930.

Leiden, Pijpenkabinet collections Pk 8.900a

- Metal chisels with round and oval diameter. Courtrai, De Bevere, 1880-1920.

Leiden, Pijpenkabinet collections Pk 8.897a, Pk 8.896a

- Stem scrapers with cylindrical hardened rod in which grooves. Courtrai, De Bevere, 1900-1920.

Leiden, Pijpenkabinet collections Pk 8.899a

- Stem file with cushion shaped file part. Courtrai, De Bevere, 1870-1900.

Leiden, Pijpenkabinet collections Pk 8.902a

- Bowl reamer in scraper version. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 8.918a

- Bowl reamer in which the rounding for the pipe bowl. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 8.905a

- Bowl file in Dutch called pissebed with oval shaped file section. Courtrai, De Bevere, 1910-1930.

Leiden, Pijpenkabinet collections Pk 8.900a

- Bowl file with globular file section. Courtrai, De Bevere, 1915-1930.

Leiden, Pijpenkabinet collections Pk 8.906a

- Bowl rim file called directie file, circular disk shape roughened on the outside. Courtrai, De Bevere, 1910-1930.

Leiden, Pijpenkabinet collections Pk 8.908a

- Heel file for the standard heel shape with special bent to work over the mould box. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 8.904a

- File for a special mouth piece with button end. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 8.903a - Mark stamp with the initial D in pearl frame. Courtrai, De Bevere, 1900-1925.

Leiden, Pijpenkabinet collections Pk 6.813a - Die or steel matrix for making the mark stamps for the pipe. Courtrai, De Bevere, 1900-1920.

Leiden, Pijpenkabinet collections Pk 17.364 - Brass stamp to mark the pipe stem, cast on a steel mould. Courtrai, De Bevere, 1880-1900.

Leiden, Pijpenkabinet collections Pk 6.812a - Die or steel matrix for making brass stamps to mark the pipe stem. Courtrai, De Bevere, 1900-1920.

Leiden, Pijpenkabinet collections Pk 17.365

Notes

[1] E1985-10-04, E1987-04-03 Review of the acquisition.

[2] Leiden, Pijpenkabinet collections Pk 7.605. On the cover of the manufacturers' catalogue “Huis gesticht in 1800” and "Maison fondée en 1800".

[3] City of Courtrai, Municipal archives, Documents on the pipe makers' marks W and WS used by the pipe makers in Courtrai, 1820-1830.

[4] G01-01-1918.

[5] Leiden, Pijpenkabinet collections Pk 3.071, Pk 9.494 and Pk 9.486.