De Jong's pipes- and ceramic workshop in Gouda

Auteur:

Don Duco

Original Title:

De Jong's pijpen- en aardewerkfabriek in Gouda

Année de publication:

1995

Éditeur:

Pijpenkabinet Foundation

Description :

Article on the history of a small factory named "De Jong's pijpen- en aardewerkfabriek" in Gouda, the Netherlands, a family-company founded in 1934 and active till 1977, including the products such as tobacco pipes and souvenir pipes.

The start of a career

In 1903, Frank de Jong was employed as a fifteen-year-old boy at the firm P. Goedewaagen & Sons in Gouda. An ordinary boy who opted for the pipe making profession, as many Gouda citizen had done before him, but few of his peers did at that time. Pipe making was not popular anymore, the quality of the product went down and the workforce aged. Frank soon turned out to be a skilled craftsman (Fig. 1). He received his training at the factory on the Raam, where at that time a few dozen pipe moulders and women that finished the pipes were working. A factory with dark, poorly ventilated rooms filled with a stuffy air. By the time Frank was a skilled master pipe maker, a miracle took place: in 1909 the factory moved to a new building on the Nieuwe Vaart just outside the city. There the working climate was much better, the factory was light and spacious because it was specially designed as a pipe factory. The well-organized workspaces undoubtedly stimulated the craftsmen to produce larger quantities. Frank developed himself to a skilful pipe moulder, but was also seen as an energetic workman.

Yet Frank de Jong had higher ideals. He did not want to live a life as a pipe maker on piece wages. Director Aart Goedewaagen recognized his aspirations and after a few years of loyal service offered him the opportunity to supervise the moulders department of the factory. De Jong became foreman and no longer received his salary by the gross but was rewarded with a fixed salary. In his new position, he controlled the production, was involved in the gross administration and ensured the general supervision of that department. In his job as a chef all kinds of obligations were heard, which he assumed resiliently.

Director Aart Goedewaagen was one of the last fully trained pipe makers, a man of tradition. He not only mastered the craft himself, but also the technique of mould making. For that skill he had been apprenticed for a year in Liège, Belgium. By the end of the First World War it was time to pass this knowledge on to a new generation to ensure the maintenance of the tools for the future. Frank de Jong was a smart and handy person who, different from most employees, could take on responsibility. The management of the company had every reason to offer De Jong a training as a mould maker. In what way De Jong received this training is unclear, presumably Aart Goedewaagen was his mentor, assisted by the company's departing mould maker.

In January 1917, Frank de Jong is officially appointed as a mould maker at Goedewaagen, at the age of just under thirty. As a salary he enjoyed the then respectable sum of sixteen guilders per week. He was entrusted the key to the storage for moulds, the place where the precious archive of metal press moulds was stored at Goedewaagen. His task consisted of the management and maintenance of the press moulds, at that time about one thousand in number. In a small workshop equipped for this work, De Jong focused on keeping the tools in optimal condition. It was a permanent grinding and tightening of the mould seams, adjusting the closing and steering pins and more technical matters. Also keeping the stoppers on diameter belonged to this task.

Furthermore, Frank de Jong has also been involved in making new press moulds in this function. When designing he used the hundreds of lead models already present in the factory. The casting of the raw mould was done by a brass foundry in Schiedam and when the rough cast arrived in Gouda he could finish them . The casts were removed and the brass was smoothly polished. Further the iron locking pins were placed in the lugs and the steering pins in the crown, a precision work. When decorations were desired, the Gouda silversmith De Vooys was asked for assistance in the engraving.

A special press mould made by Frank de Jong is number 400 of Goedewaagen (Fig. 2), better known as Clownshag met hoogen hoed (shag (pipe) with clown wearing a top hat). It is a small and short pipe as a type also known as ice pipe because such curio goods were sold to ice skaters during the winter, more than to smokers. Of course De Jong only took care of the technical work, the merit of the design comes from another yet anonymous person.

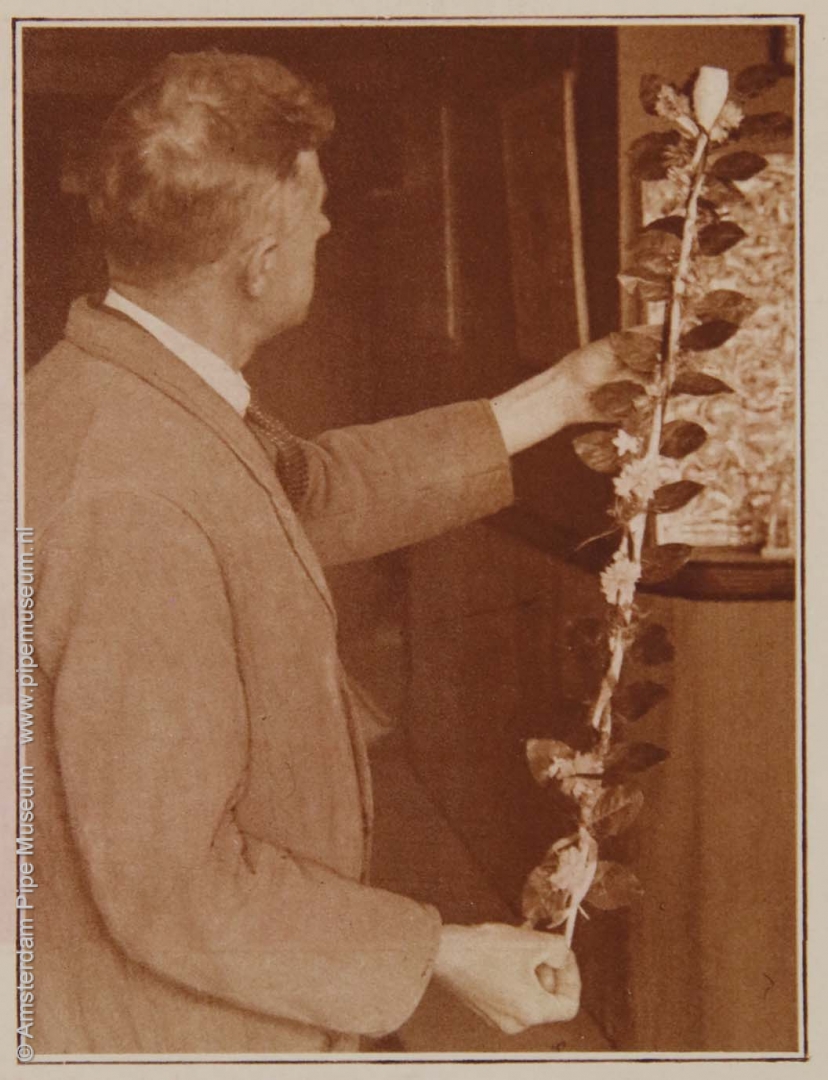

For Goedewaagen Frank de Jong was an obedient and sincere man, albeit strict for the workmen he led. In terms of position, he was between the director, who was called Mr. Aart on the work floor and the labourers who produced the clay pipes. A situation that will not always have lead to friendly contacts with the workforce, certainly not because his position was rewarded with a generous salary. In course of the years, the number of pipe makers at Goedewaagen shrank and De Jong also oversaw the so-called women's department where the pipes were finished and stroke burnished. In fact, the entire production of the traditional clay pipe felt under his supervision, except for the firing process. When a brochure about Royal Goedewaagen was published in 1931, Frank de Jong was depicted in a pontifical manner with the pride of the pipe factory in his hands: the meter pipe or bruidegomspijp (bridegroom pipe), a product still in stock, but at that time no longer produced (Fig. 3).

The step to independence

In spite of his successful career, Frank de Jong dreamed about his own workshop. In this way he maintained close contacts with the last small pipe makers, the workshops of Nico van Duyn van Velzen and Van den Broek. Dealing with these small independent entrepreneurs was sometimes envied by his factory colleagues who were not allowed to. This jealousy is evident, for example, from an anonymous note that was delivered to the management of Goedewaagen one day. It reads: "M., Frank de Jong certainly wants to start for his own, at least he left the home of Van den Broek on the Raam (street) on Friday evening at half past eleven, that two spells some". A cowardly click, now stored for eternity in the archive of the Goedewaagen factory.

That this allegation contained truth was proved several years later. In 1934, Frank de Jong made his decision: he resigned the Goedewaagen company and started his own workshop. By then De Jong is 45 years old. The step to independence was carefully chosen: the moment when his children are old enough to assist him in his own workshop. At the same time, his responsibility as a cost winner had diminished, so that the risk of a financial debacle would not directly affect his family. The new factory is named De Jong's Pijpen but is officially called Firma De Jong & Co. With the addition Co. is probably meant the support of the before mentioned Van den Broek, who was already mentioned in the allegation of 1927. The factory, or more rightly workshop is located on Gouwe number 192.

Little is known about the size of the workplace and the personnel in that first period. Frank’s son Arie remembered a few names in 1977: Jac de Jong, Gerrit de Bruin and Steven Meijer as pipe moulders. In addition, Trui de Jong worked as a finisher. It is clear that it concerned a family business, while additional workers were undoubtedly recruited from the two established factories. Since there were about seven people working in the best years, the designation factory is a bit overdone, even if it is not a one-man’s workshop.

The range of pipes from the early period is reasonably well known. We are informed by the tools that survived in the factory. They largely came from the inventory of the Royal Goedewaagen. The press moulds were selected by De Jong personally from the Goedewaagen mould archive, most presumably without the knowledge of the management. After all, a manufacturer does not like to train his competitors and thereafter give them tools for dowry when they become self-employed. In addition, on the final settlement of De Jong's pay by Goedewaagen in 1934 nothing is mentioned about any tools acquired.

What De Jong chose from the Goedewaagen mould archive and took with him is in line of expectations: press moulds for a starters assortment: beakers, doetels, oval shaped pipe bowls and a single curved pipe bowl. In addition, a few more striking shapes were selected, such as a basket. These tools were supplemented with the press moulds that Van den Broek already possessed, who had been self-employed up to that point and had bought up some tools from liquidating workshops. Together they came to a rather complete assortment in which the most common smoking pipes were represented. Because the pipe moulds from the Goedewaagen factory were equipped with a chiselled mould number on the outside, these numbers were carefully removed in the hope that proof of the origin would become unclear.

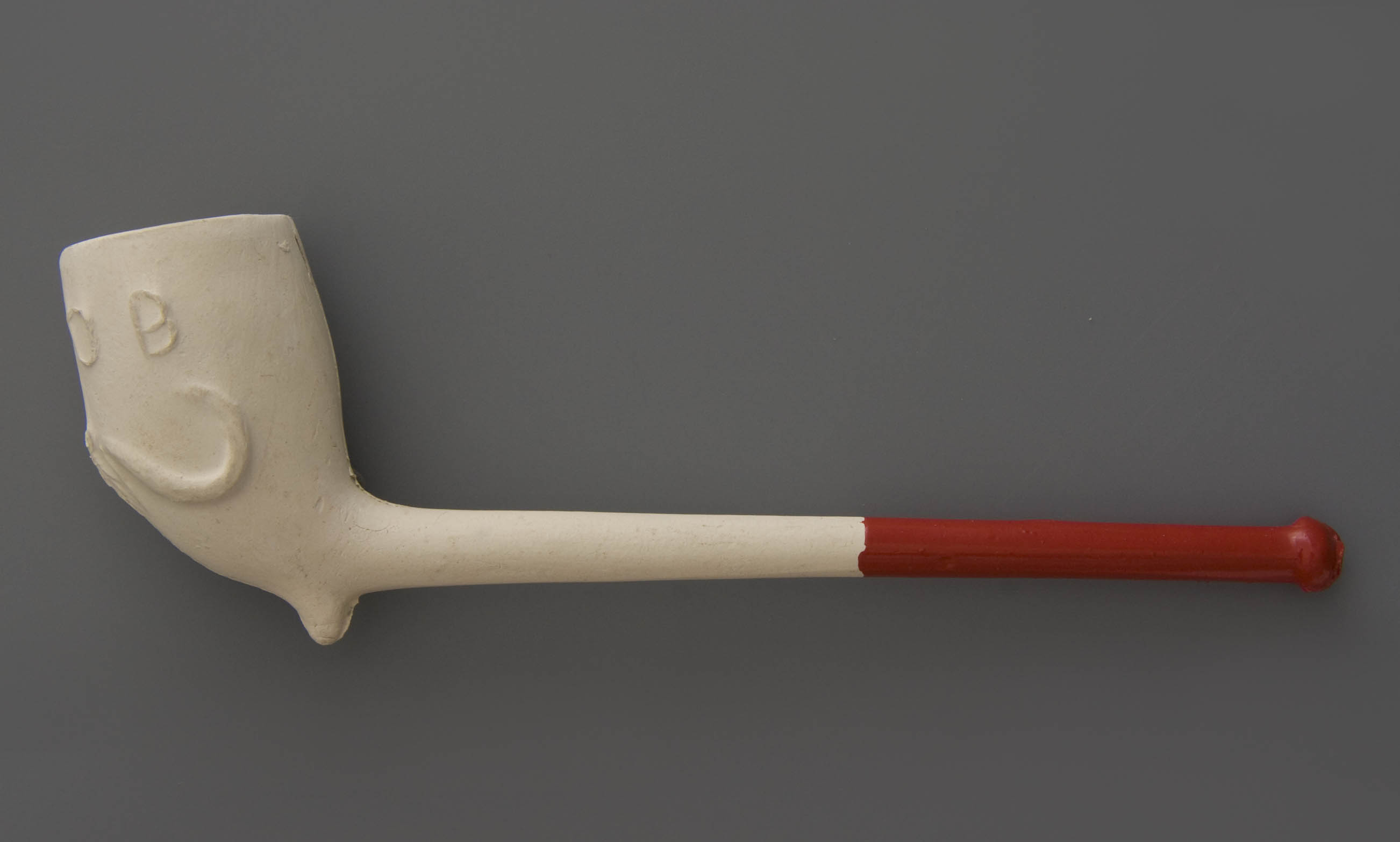

The new factory will focus on simple clay tobacco pipes for both smokers and souvenir shops. According to tradition, the conventional smoking pipes are still provided with a mark on the bottom of the bowl. Because the marking of pipes was customary, De Jong adopts his own, an unexpected and completely new mark: a rather undefined type of waffle motif, in the workshop itself called the nail head (Fig. 4). The mark is however not printed with the head of a nail as it looks like, but with a conventional mark tool of which the engraved surface was flattened and provided with a diamond pattern. Naturally, this mark served merely as a general reference to a certain quality of the product. The target group of De Jong consisted mainly of smokers with limited means and tourists. The first category did not have the means to make a quality requirement, the second had no understanding of the significance of the pipe mark.

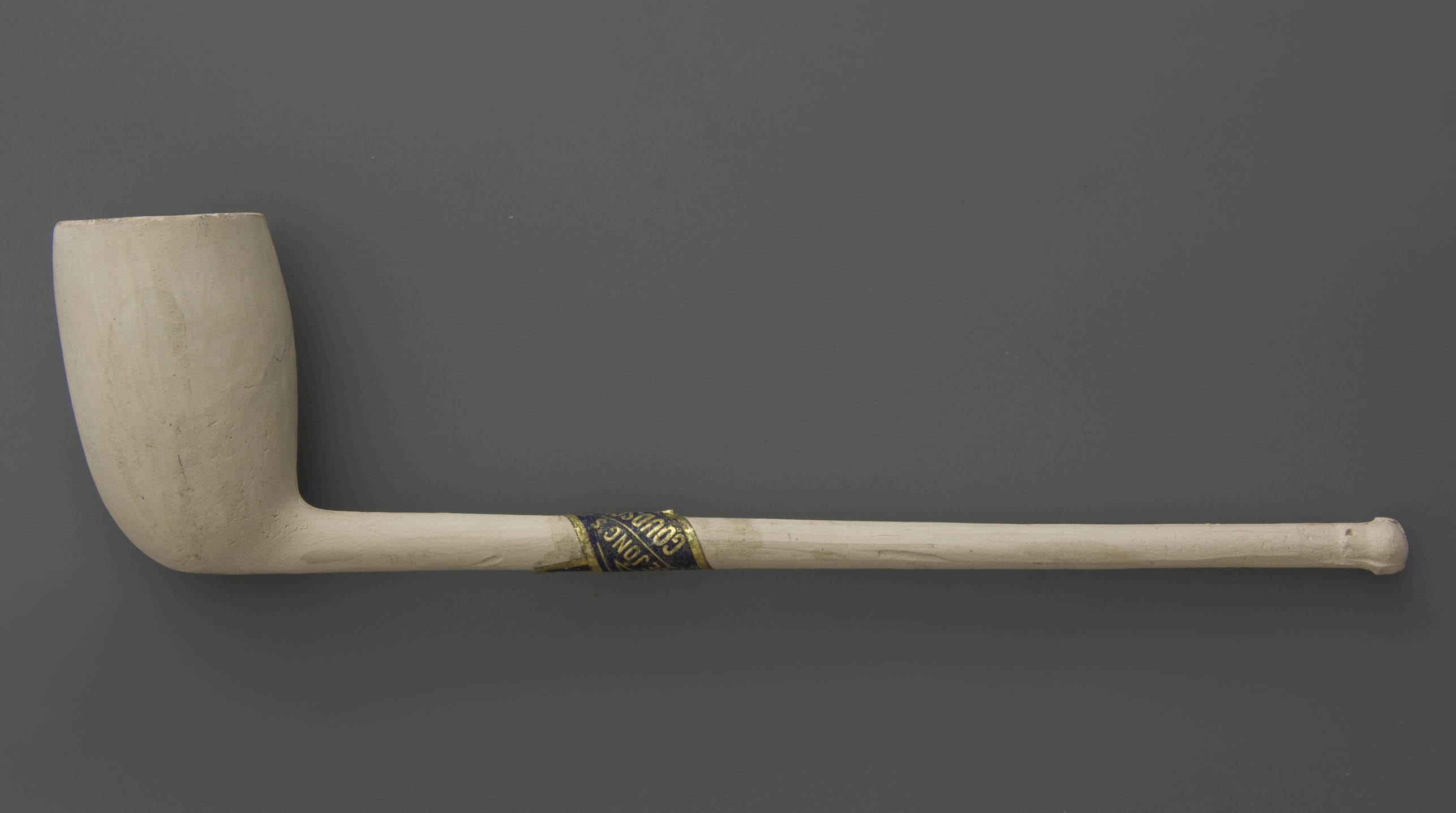

In addition to the stamped pipe makers’ mark, De Jong also launch a stem label that was still stuck around the stem of the clay pipe as standard. Frank de Jong follows the successful design of Goedewaagen: a blue label with the inscription "GOUDSCHE PIJP" including the name and the address (Fig. 5). When this label comes on the market, Aart Goedewaagen speaks to him about it, because the distinction between the two designs is too small. Immediately, De Jong switches to a different colour scheme and chooses a label with a silver or gold background and a different colour blue. The inscription remains “DE JONG & CO. GOUDSCHE PIJP GOUDA", so that typographically the resemblance with Goedewaagen labels continues.

In addition to this label, there is a second label design printed with "DE ECHTE HERTEKOP PIJP" (the real deer head pipe) (Fig. 6). This rather cryptic inscription was inspired on the then popular pipes that were brought on the market by the pipe importer Vasterman. It concerns briar pipes that are marked with a deer's head on the stem. This label therefore speculates on a name recognition, even though there is no comparison with the briar pipes of the competitor at all nor with the representation of his brand.

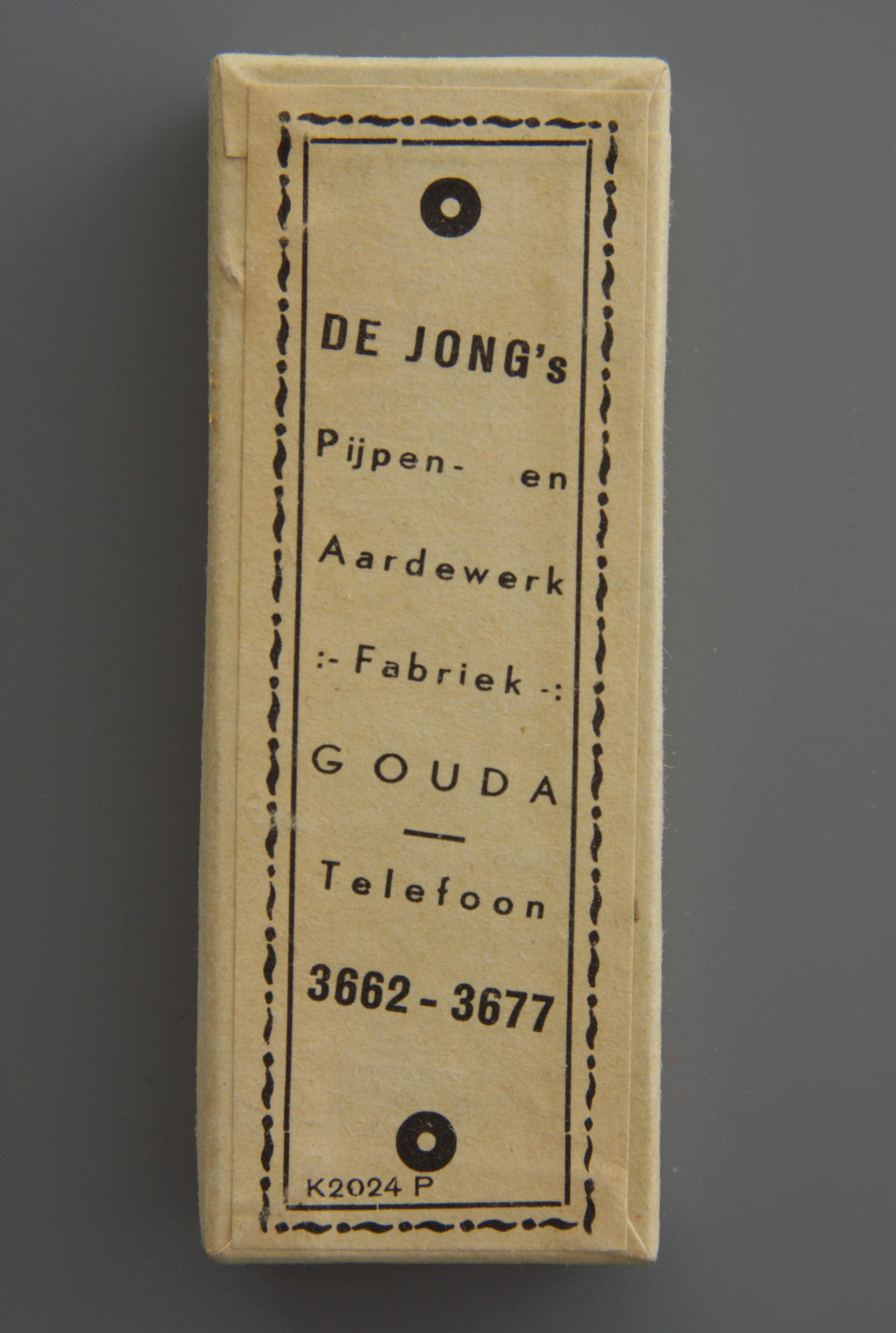

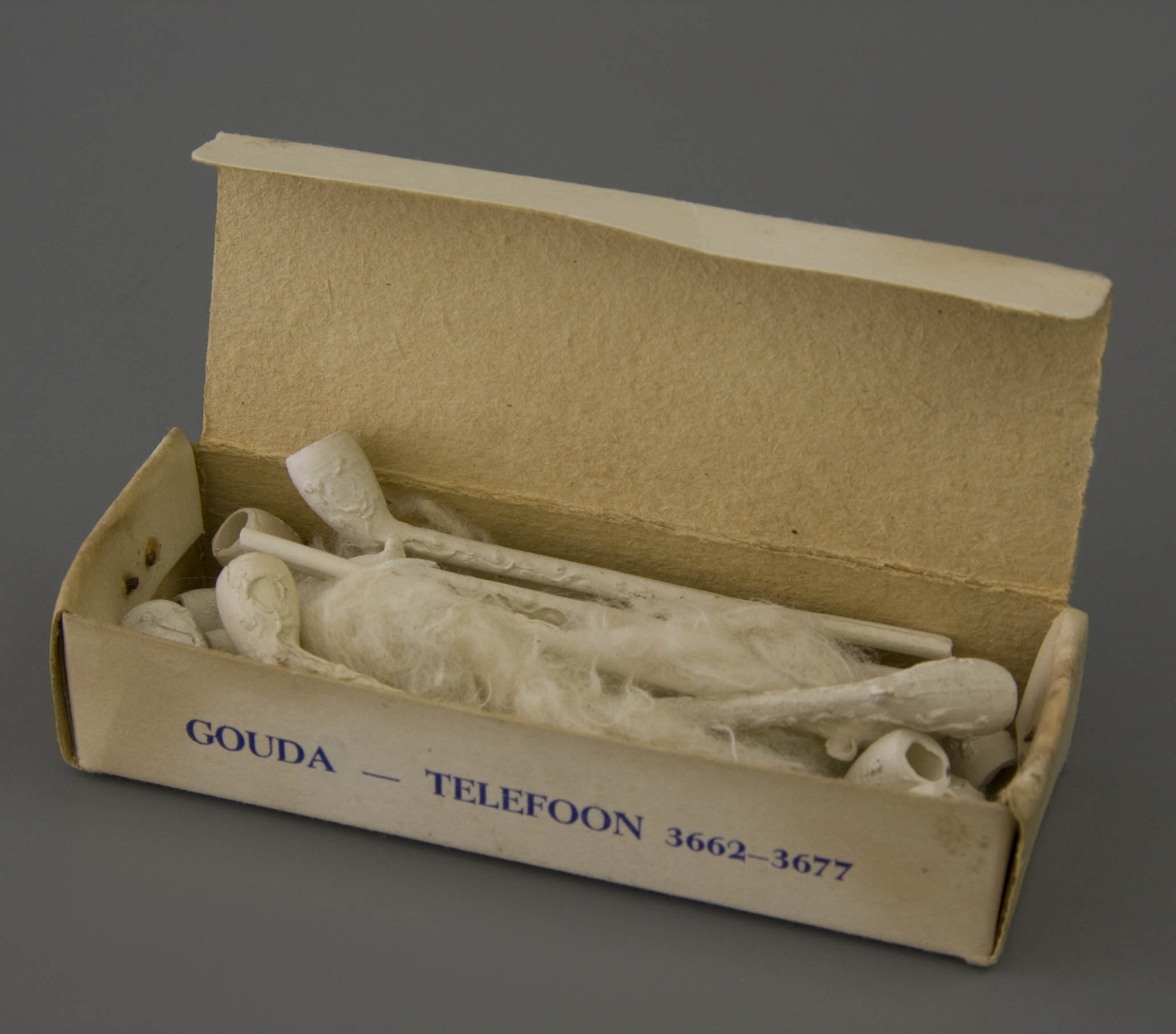

Apart from being a production workshop, De Jong also traded pipes. In the long clay pipes, for example, it was difficult to compete with the existing companies, of which Royal Goedewaagen was the most important producer, followed by P.J. van der Want Azn. That is why the longer pipes were ordered at these factories and resold after they were provided with their own name or painting (see Fig. 38). In addition pipes were also purchased from Nico van Duijn van Velzen, whose products were also painted in the De Jong workshop. A special label was used for shipping in boxes (Fig. 7).

The assortment of pipes from De Jong

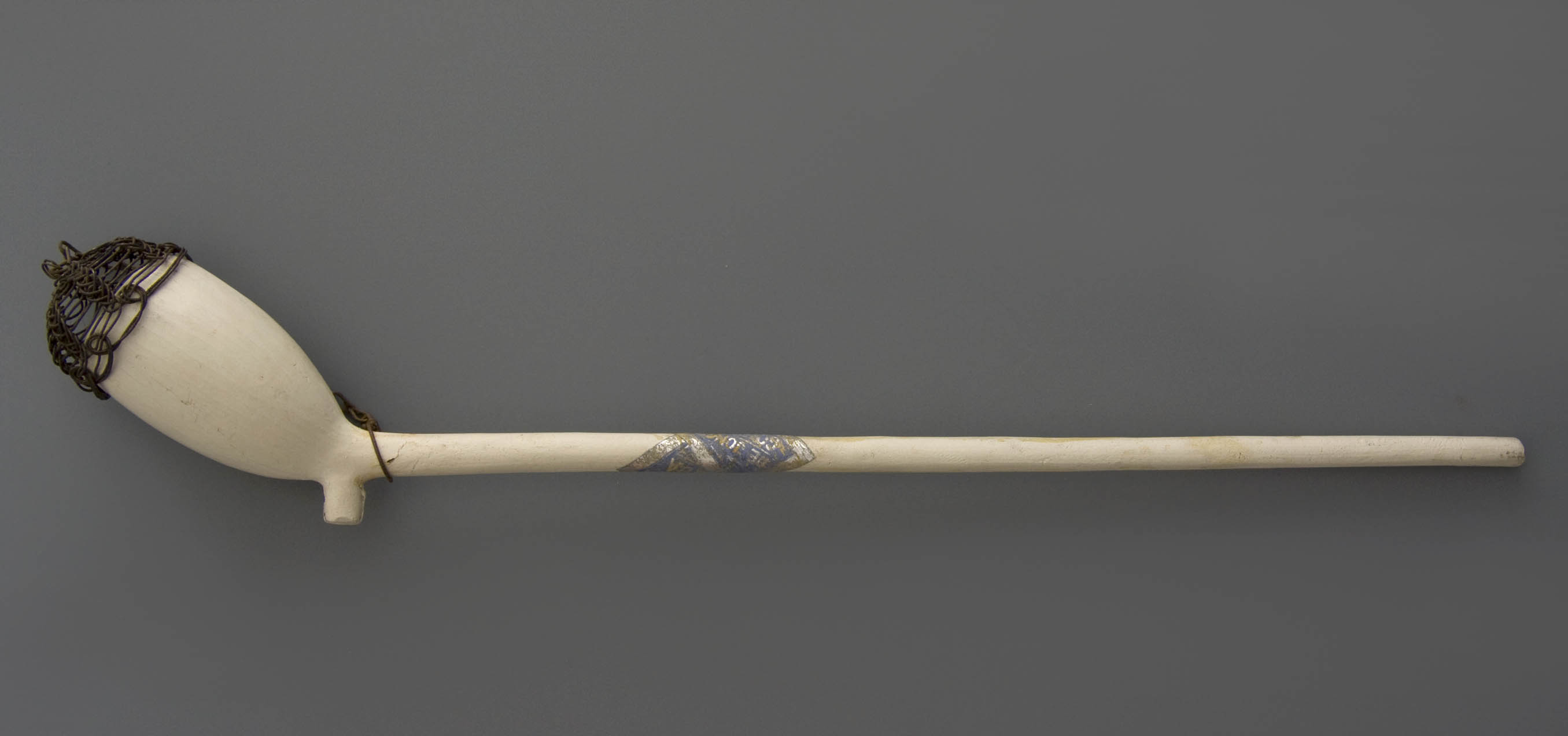

In De Jong's factory, the longest types of clay pipes were never in high demand. There is only one long pipe (50 centimetres) in production having an the traditional one with oval Gouda type bowl. This pipe is sold as pipe with a double twisted stem, since the target group is mainly tourists. Half long pipes were also produced, and here again only sold as a pipe with a single twisted stem (Fig. 8). Obviously this has to do with the problem of making pipes with perfect straight stems. Some more common tobacco pipes are the long and short kantoorpijp (litt. office pipe), a shape that we now designate with doetel (Fig. 9). Furthermore, the beker (litt. beaker) with a slimmer bowl and a shorter stem (Fig. 10). Another item is the sportpijp (sports pipe) (Fig 11) which has the shape of a briar pipe. Hardly a serious smoking pipe is a heelless model with a decoration derived from a braided basket (Fig. 12). This pipe is more a soap bubble item for children than a serious smoking pipe. The press mould originates from the Goedewaagen factory.

The most unexpected pipe in the range is the Mercurius pipe, the bowl shaped after the head of Mercury, complete with wings on his hat (Fig. 13). The design for this pipe dates from the 1870s. Production in a slightly worn press mould continued until 1950, mainly as a pipe with a twisted stem. This not seriously figural pipe was called the Achilleskrul by De Jong, proving that the Greek mythology was not his cup of tea.

In the years that followed, De Jong introduced several new models to complete the range. The first is a large bowled shape known as Portorico, copied from export pipes from the last part of the nineteenth century. The press mould for this product was made by De Jong himself and given the moment of creation in the 1930’s?, this pipe model is rather unexpected (Fig. 14). These newly made press moulds are characterized by a somewhat harder, bronze-like casting with a slightly reddish tint. The casting was done by Du Chateau. One of his own designs stands out: a cigar holder or the so-called tip (Fig. 15). Even a rough casting from the press mould is preserved (Fig. 16), a simple unfinished pipe mould without pins and not yet smoothed. It is a good example of how a mould looks like when it comes from the bronze foundry. It is not uncommon to cast several copies of a new press mould, even when they are not all finished and used. Apparently that is what happened here, because produced pipes are also known. Then the pipe shows a spirally arranged hatch on the six sides.

A special clay pipe from the range is the Goliath, the prestige product of the factory (Fig. 17). This model was also introduced in the 1930’s and the press mould was again made by Frank de Jong himself. Unfortunately, the design is not really strong, while the finish of the surface is not very smooth. It is a short pipe with a very large almost water-headed curved bowl, marked between bowl and stem by a firm heel. The pipe is not intended for smokers, the bowl is too large and the weight too high. Target group is the souvenir market and for that reason most of the copies got a colourful painting before they were sold. This product could also be supplied with a special inscription or a decoration on request.

Less general and by far outdated in the 1930s is the RAOB (Fig. 18). Just like the Portorico pipe, it is a pipe shape originating from the nineteenth century, of which most of the smokers probably did not understand the meaning of the decoration. Also in this case, we see that the maintenance of the mould has been poor. For example, the letters RAOB are engraved rather clumsy and unsteady with the result that the print is not sharp and unsteady. Once again, given the period of use, perfection no longer mattered. Notwithstanding this poor quality, this model is produced in large numbers, the worn press mould is drastically repaired in the fifties, so that the pipe becomes a fraction larger and the relief slightly changes (Fig. 19).

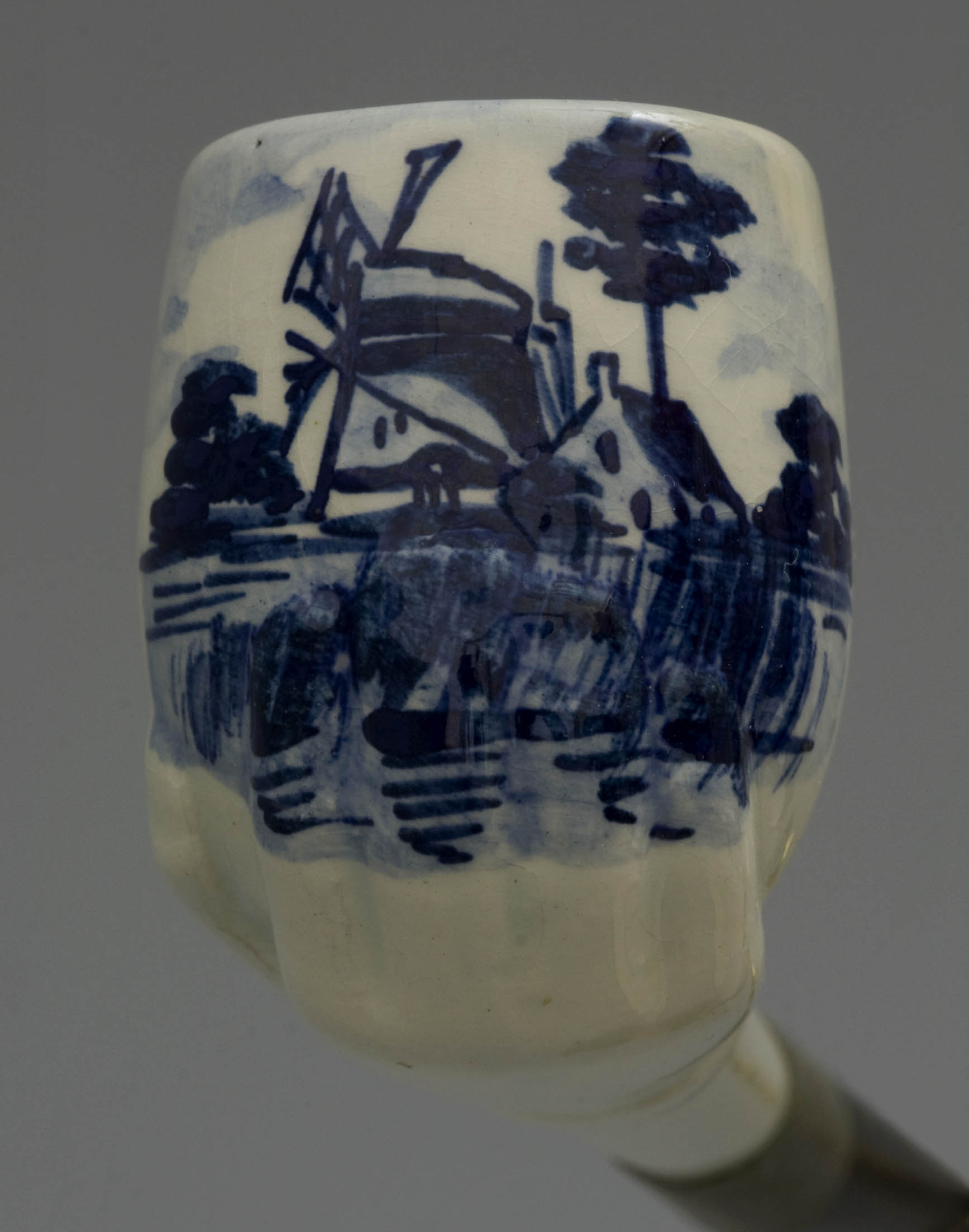

A remarkable item is the stub stemmed pipe with a billiard bowl and short stem ending in a thin cuff (Fig. 20). Once again, the execution of the mould is below level: the shape is not only impure but the surface is bumpy and uneven everywhere, while even the cuff edge is not tight. Clearly, the lack of good tools for making and maintenance of the moulds is lacking in Frank de Jong’s workshop. This is rather unexpected for a person with more than fifteen years experience in designing and making moulds . These pipe bowls were mounted with a wooden mouthpiece, thousands of which were still in stock in Gouda for almost no cost. They were the left over from the First World War, when hard rubber was no longer available. So, both for the bowl and stem it was a simple product without any pretension, intended for the smoker with little money to spend. Only when the pipes were painted and varnished they were somewhat acceptable. Then a Dutch landscape with windmill obscured the uneven surface (Figs. 21-23). We may expect that Frank made quite a good business with this pipe in the period of the great depression.

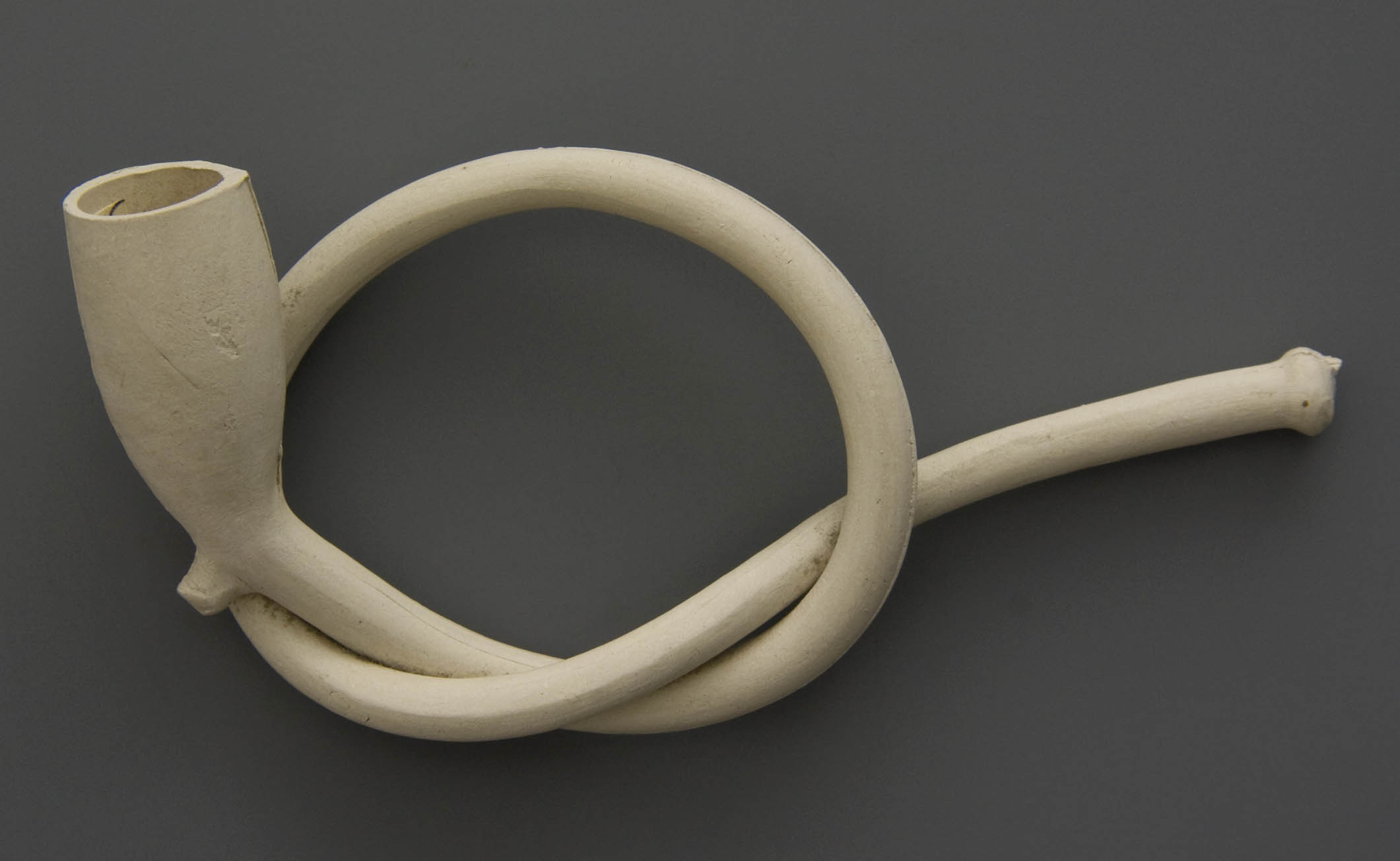

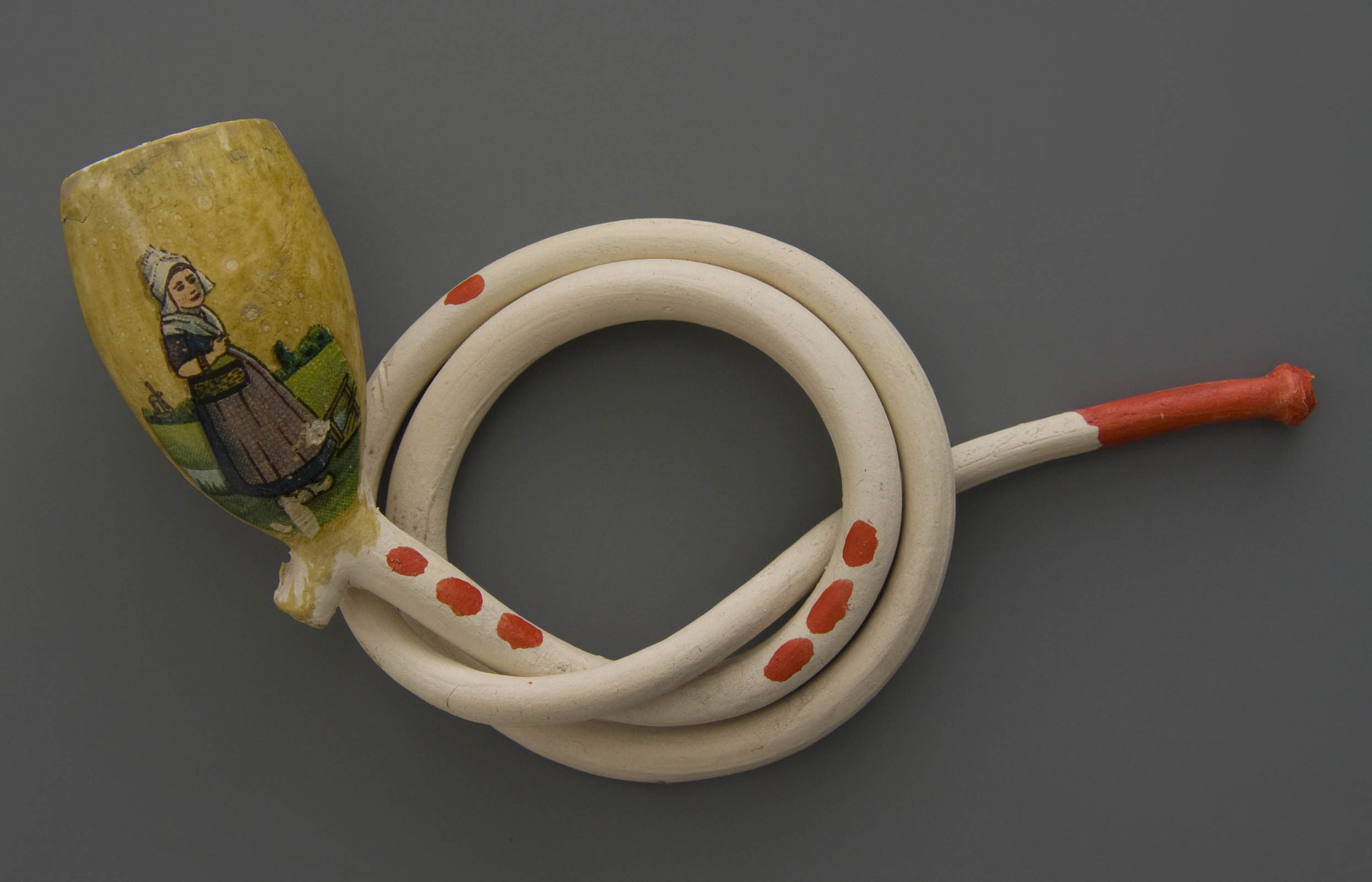

A specialty of the workshop that also meets the needs of the souvenir market in Gouda is the pipe with the twisted stem: the stems of tobacco pipes and cigar holders were twisted along a wooden bobbin to a single or double knot. The pipes are available in different sizes: the single and double loop tobacco pipes (Fig. 24), the cigar pipe and the cigarette pipe (Fig. 25) and even the miniature as smallest also with looped stem (Fig. 26). Many of these pipes were painted in simple colours and found their way to tour skaters on the ice. They are therefore also known as skating pipes or ice pipes.

Within the souvenir market it is understandable that the miniature pipe takes an important position. De Jong even makes some new press moulds for these miniatures in different designs. The most typical is a pipe with an oval bowl, a small heel and a straight stem, in fact the miniature of the standard Gouda clay pipe (Fig. 27). This species is supplied in two sizes, but both no longer than 6,5 centimetres. In addition, a so-called bullekopje is made, a pipe with a curved bowl (Fig. 27 below). For the tourist these miniatures are available in two versions of carton boxes (Fig. 29) containing a full or half a dozen (Fig. 28) . A larger size box is available for the wholesale, in which a maximum of a gross pipes could be sold (Fig. 30). Rumour has it that the miniatures were made at home during the evenings as extra income.

Many products for the souvenir market are decorated with an appropriate painting. This initially happened with oil paint with little variation in terms of subjects. The most neutral is a painting in a simple floral pattern with the indication of city or country on the stem (Fig. 31). Another popular motif is the painting of a Dutch windmill in simple black lines flanked on both sides by bushes in green, applied according to a kind of tampon printing technique (Figs. 32, 33). Most of such products are covered with a yellowish transparent lacquer after painting, On the stem the city or country is written, whether or not preceded by the word souvenir. The most primitive painting is performed on one side only and we usually see it on the right side of the pipe bowl. Strangely enough, the small factories in Gouda always choose the right bowl side for their painting, while a factory like Goedewaagen makes the painting standard on the left side of the pipe bowl.

For the sale in the city, Gouda's monumental town hall was the most popular motif, and here too the text "GOUDA" or "SOUVENIR GOUDA" explains who the buyer was. In a rare case, the façade of the weigh house is chosen as another iconic Gouda building. The painting is set up in smooth black lines. Since the hand-painting soon gets too time-consuming, decals from the town hall came into use (Figs. 34-37). When the pipe is then varnished, the illustration becomes one with the environment and it suggests hand painting. Sometimes the pipe is provided with a general illustration (Fig. 40).

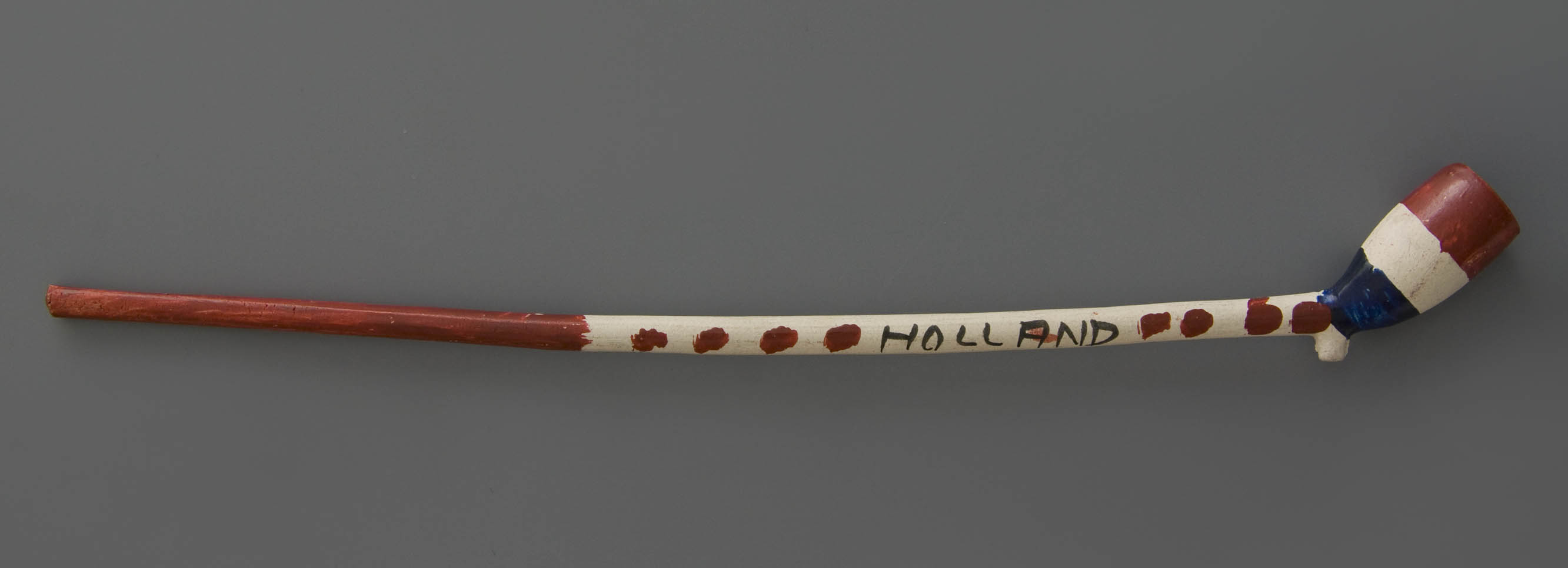

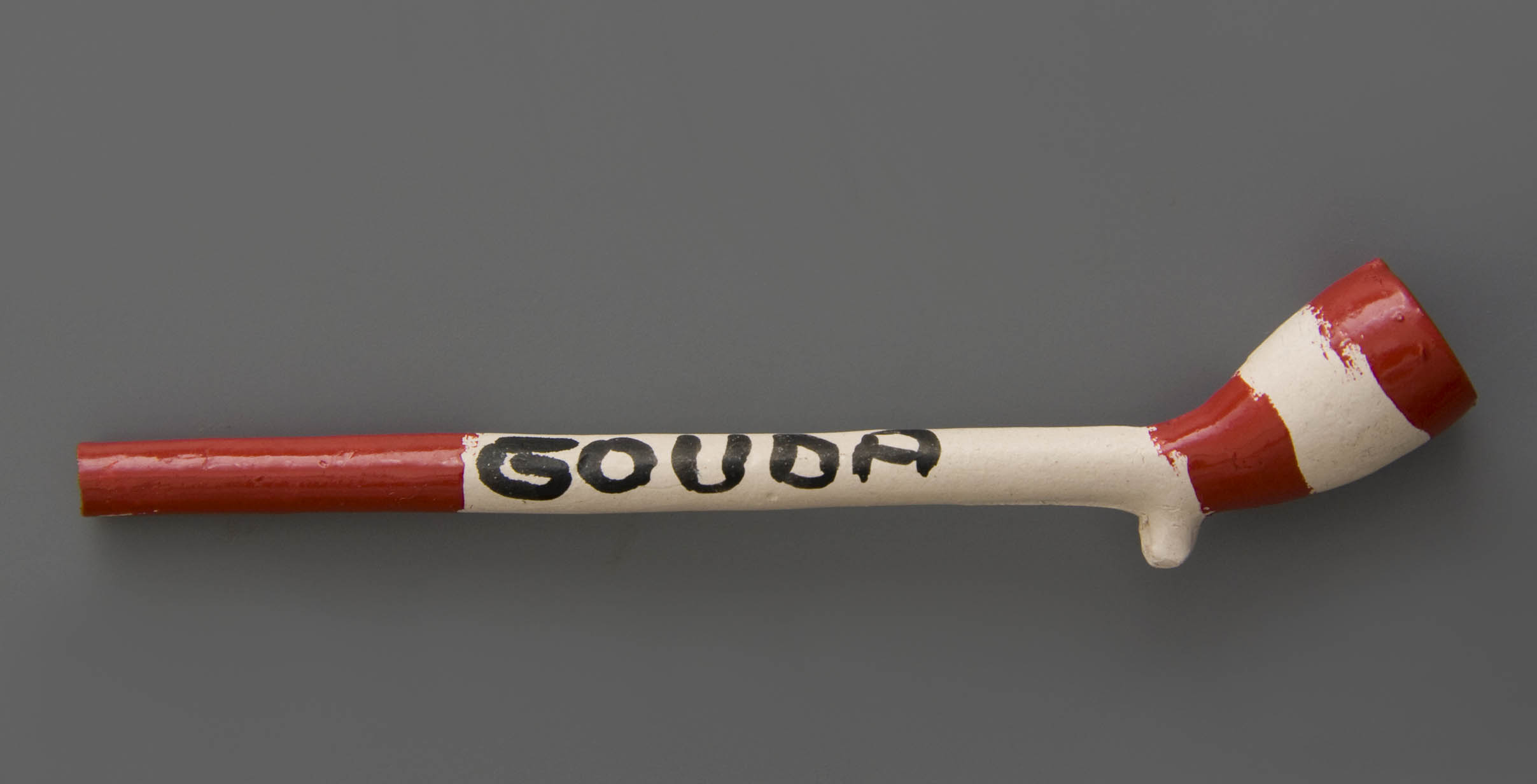

The most common decoration is the pipe painted with a simple red track and a blue track with the white clay colour in the middle making the Dutch flag (Figs. 41, 42). Another version shows red twice relating to the colours of the Gouda coat of arms. That this last painting was invented during the Second World War when the use of the national colours was not allowed, is doubtful. This colour scheme is still in use until the 1960s. These pipes are mainly sold as ice pipe to tour skaters from the surrounding areas when visiting Gouda. Coming back home with an unbroken pipe proved that the skater didn’t fall on his tour.

Restart after the war

Little is known about the ins and outs of the workshop in the 1940s. The factory moved from the Gouwe to the Kleiweg for an unclear reason. The period of the Second World War would not have been easy, especially because in Gouda many workers were recruited for labour camps by the Nazis. The fuel for the kilns was also scarce and therefore expensive. After the war comes the period of reconstruction, a period in which the clay pipe gradually loses its attraction as a smoking pipe, while there is not much to earn on the tourist market either. Despite this malaise, De Jong's factory survives. At a presentation of their factory during a fair in 1947 they even get a royal visit in their stand.

A new product line was started around 1950: the colouring clay, in Dutch doorroker. This typical Gouda invention has been a great success since 1910 and three Gouda factories had already made their fortune in this modern product. Also De Jong saw his market opportunity. When the sale of the traditional metal moulded clay pipe declines further and moreover there is a lack of craftsmen in traditional pipe making, this new production offers chances. The colouring clay is not pressed in metal moulds, but is instead produced in a slip casting process. Liquid clay is poured into a plaster mould and when a clay wall has deposited in the mould, the remainder of clay is poured out. Afterwards, the casting seams are removed with a sponge and when dry the product can be baked. After a first firing, the pipe bowls are glazed to go to the kiln for a second time. For all this labour hardly any training is required.

The production of the Gouda colouring pipe fits in with the expansion with all kinds of other ceramic products, a phenomenon that we saw in other Gouda factories forty years earlier. Remarkably De Jong only starts this production line when the economic success is already clearly over. The first model is a billiard bowl of which the bronze press mould is now replaced by a plaster mould, but the poor design is not adjusted. With a transparent glaze and a blue under glaze painting, this product looks much more luxurious than its painted and lacquered predecessor. What strikes us is that the blue landscape is painted with extraordinary skill (Fig. 44). Obviously, a yet unknown painter was hired who had already gained extensive painting experience at another factory.

After having achieved a satisfactory sale with this pipe shape, it is time for new designs. Then De Jong introduces a beaker shaped pipe bowl and a more fashionable bowl with a flattened bulbous shape known as Prince Albert (Fig. 45). The mounting with the wooden mouthpiece is now being replaced by a black plastic mouthpiece, which clamp in the ceramic stem with a cork. Here, too, we see the same paintings of landscapes with windmill and haystack in the woods. The blue Delft palette is being extended with a multi-coloured painting.

In the following years another renewal occur. In order to match the modern and professional appearance as that of the leading firms Goedewaagen and Zenith a mounting with a metal cylinder is added . In the end, the range of pipes runs into about twenty pieces. Most specimens are functional tobacco pipes, shapes that are pretty much the same as produced by other factories. However, the design has not been copied directly from the competitor, but all models were created in their own workshop. They are characterized by a smaller size, sometimes with a rather floppy appearance.

The most in demand of the colouring pipes are the ordinary curved bowl and the beaker. Of course, the shape with the swallow tail is not missing either, a pipe that can stand both vertically and horizontally (Fig. 46). Some pipe shapes are more fancy, such as the bird's claw and the human hand. Even a stummel shape is part of the range. A single product is entirely made of clay: the simple cigar and cigarette holders known as stiftje (litt. pin) (Fig. 47).

Another of De Jongs copies of the major Gouda pipe factories is the so-called mystery pipe: a slip casted pipe with apparently no decoration at first sight, but an image will appear when smoked. When the pipe is smoked and the turns brown by the nicotine, this image will show in white against the dark colouring background. De Jong's change in the production is that he makes a hand-painted picture in white tin glaze applied under the transparent lead glaze. . The larger Gouda factories produce these images with transfer printing or with a rubber stamp. With De Jong, this image has a much more joyous appearance thanks to the hand-painting (Fig. 48).

All the slip cast pipes are finished with a transparent glaze. Since the factory lacks the technical knowledge about the balance in tension of the shard and the glaze, many problems are encountered. Numerous products soon show hair cracks and start to leak when smoked. In that respect, the De Jong mystery pipe was clearly a second-rate product, rich in imperfections. Yet this problem for the souvenir sale is not an insurmountable problem. Most of the pipes are sold to day trippers who will never come back to complain. Moreover, most pipes left Gouda as a souvenir without ever being smoked.

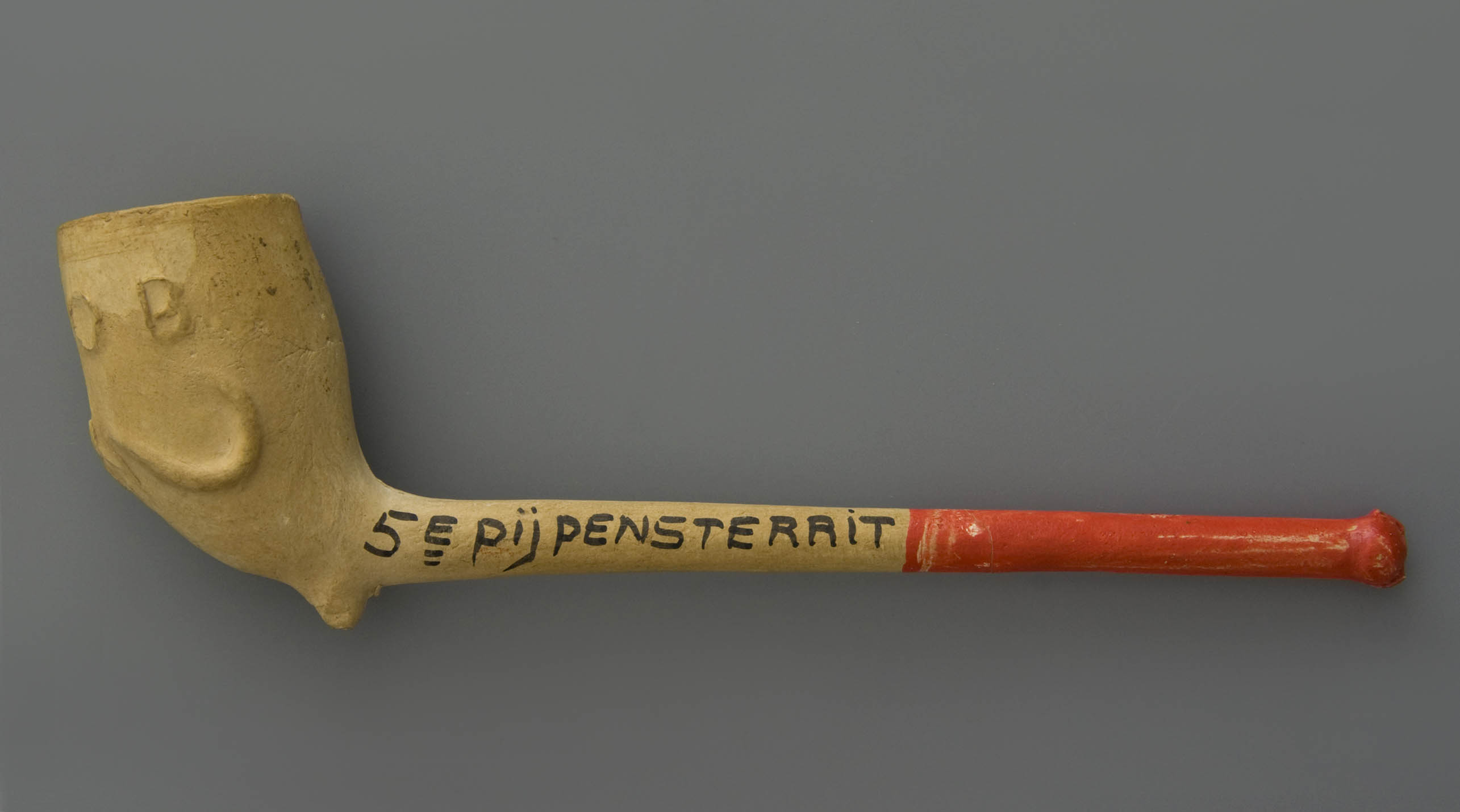

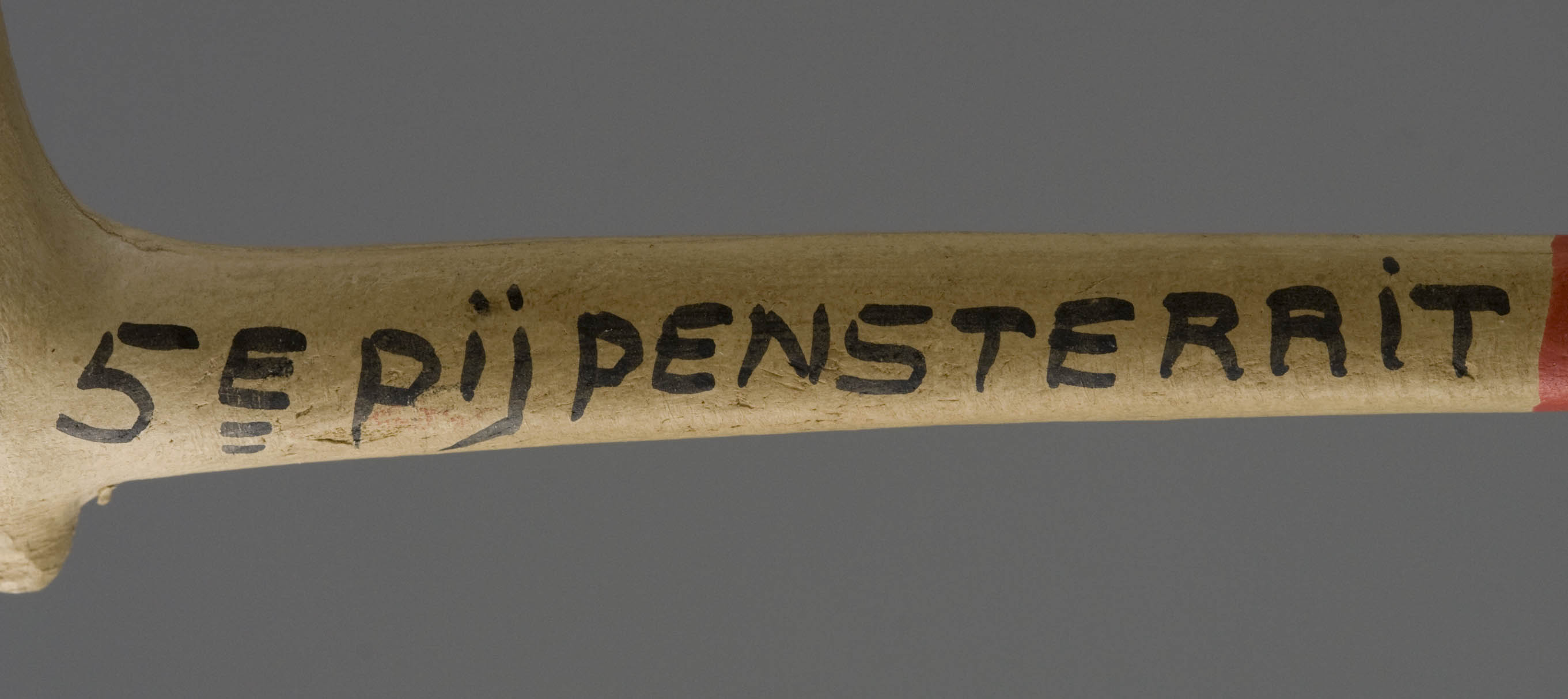

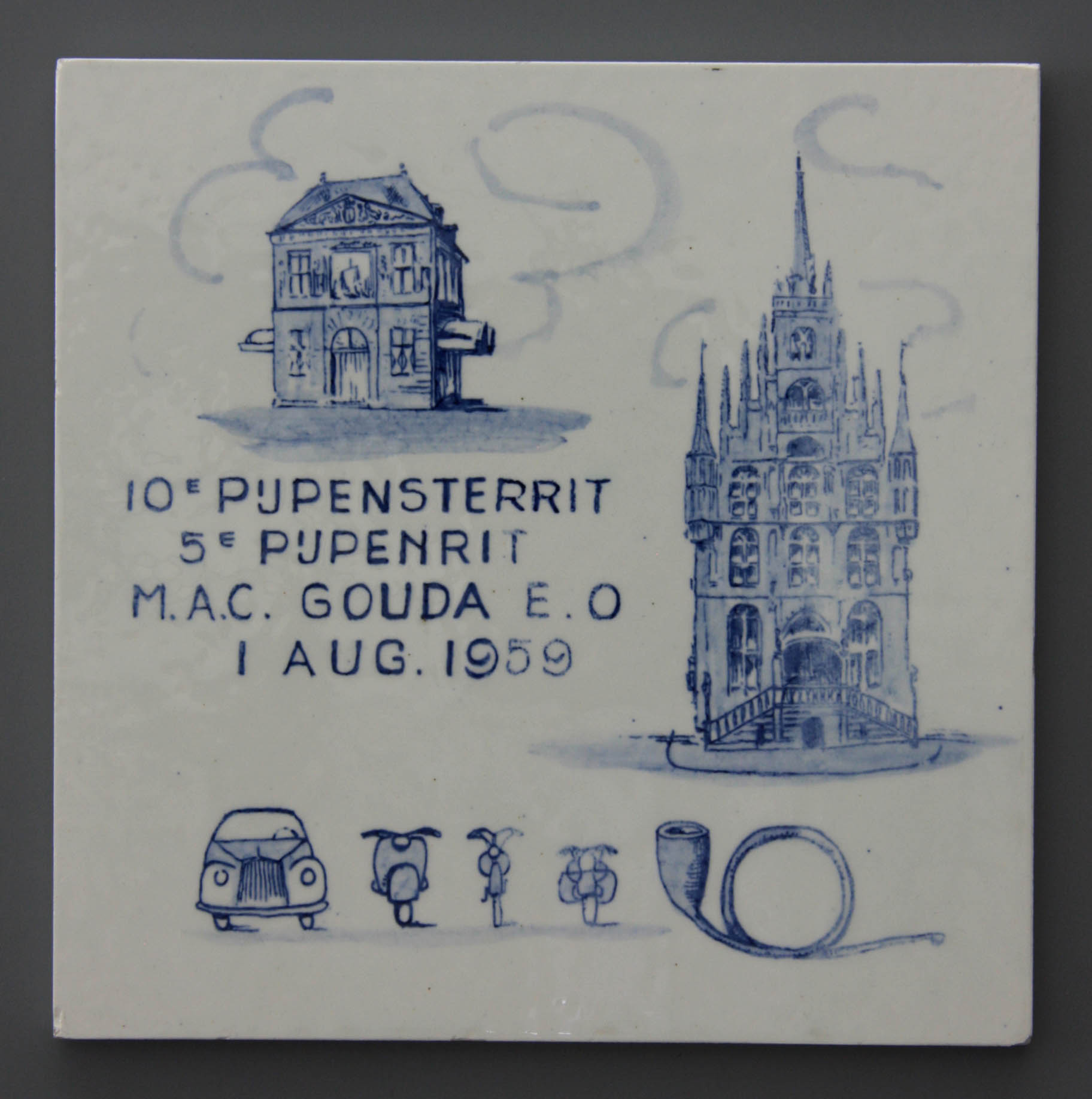

In addition to the sales in Gouda, many souvenirs are made for a specific target group, as witnessed by inscriptions such as "AMSTERDAM-HOLLAND", "VOLENDAM" and "VALKENBURG". In addition to the general souvenirs for retail, special orders were possible. For instance, De Jong receives an annual commission from the Motor Club Gouda for the memorial pipes of the pijpensterrit (star drive) (Fig. 49). It concerns all kinds of short and simple pipes with inscriptions commemorating this event. For example, they mention "5th PIJPENSTERRIT", sometimes with data such as "20 JULI 1957", "19 JULI 1958" or "30-07-1960". We also see inscriptions like "M.A.C. GOUDA & OMSTR.". In fact, such products are only a little different from the more general ice pipes.

Addition with souvenir goods

In the 1950s, De Jong looked for other products that could ensure the factories continuity. The mystery pipe, whose production was in fact in line with the general ceramic manufacture, was the incentive for a widening to other ceramic products. So one gradually starts making all kinds of knick-knacks, as long as it can be produced within the own technical capabilities. A trivial article is, for example, is a figural cigarette pipe (Fig. 50), the bowl of which has the shape of a clog. The idea is not by De Jong himself, but both Goedewaagen and Zenith produced these figural cigarette holders. Again the simplicity of this product is striking. The finish in Delft blue is in oil paint.

A product between pipes and earthenware are the wall racks for miniature pipes. The first design in a shield shape is already conceived in the 1930s (Fig. 51). This rack exists in two sizes, as was the case for the miniature pipes themselves. The earliest examples are of the so-called cold paint ceramic, a crisis product where no glaze but only paint and varnish were used. With this finish the producer did not have to do a second firing, which saved the expensive energy and in addition avoided the risk of glaze crackle . This cold lacquer product is characteristic for the 1930s, although production continues until the 1940s. In later times, these racks are always glazed and painted in the fashionable Gouda pottery (plateel) palette (Figs. 52, 53). The subjects are strongly related to the colouring pipe and often the hand of the painter can be recognized.

A new design for a pipe rack comes on the market around 1960. It has a wall plate in diamond shape with contoured edges painted in Delft blue (Fig. 54). In fact, this rack is inspired by Goedewaagen, although it is coarser and heavier. In execution it resembles therefore the old shield-shaped rack that had been copied from Ivora. While the larger Gouda factory switched to a stronger shard and higher quality glazes, the ceramic product of De Jong did not give any innovation. The shard remains coarse and heavy but therefore resistant to warping in the kiln. With the modern pipe rack, the Delft blue palette is the most common and the favourite motif is again the town hall of Gouda.

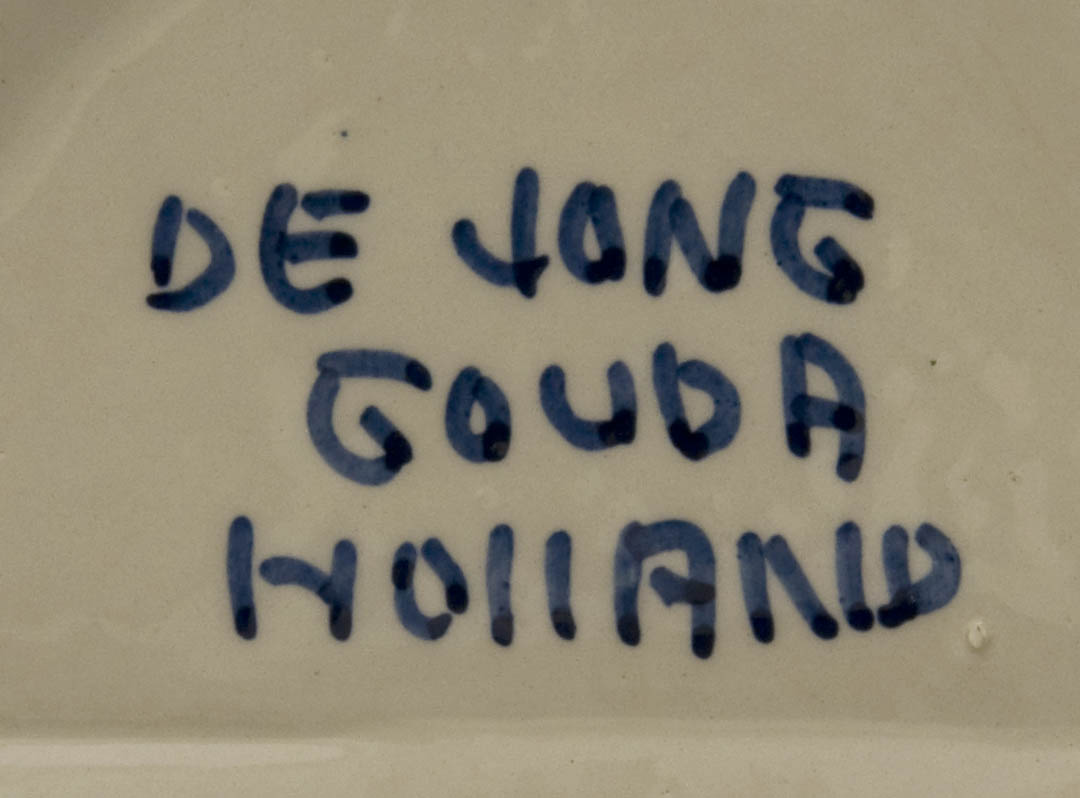

Gradually the factory broadens itself to a pipe and earthenware factory which is reflected in their letterhead (Fig. 55). For the ceramic products, the plaster mould is not made in-house but ordered ready-made. De Jong’s factory focus on pouring, glazing and decorating the objects. Most of the ceramic production was commission work, quite different from the earliest time of the pipe making when production was mainly for the stock. Sometimes work remains limited to painting and glazing while the biscuit product was bought at colleagues or at factories that liquidated. Gouda knew numerous other small workshops that had specialized in this simple ceramic knick-knack. The simple casting process, the ready-made clays, factory glazes and the cheap electric kiln, all this made it so easy to start an individual workshop.

A nice example of such a curiosity article is the souvenir of a walking tour in 1957. Very appropriately the memento takes the shape of a signpost, known all over the county along walking paths, executed in the characteristic Delft Blue palette though Delft flowers are missing (Fig. 56).Typical for De Jong the painting consists of text only. In this case too, it is an item that could be delivered annually to a regular customer.

The series of commemorative tiles for a variety of occasions is both touching and extremely shabby. A example still commonly found are the wall tiles dedicated to the yearly Gouda event on motor racing; the tile as a token of participation became a tradition over the years. It is interesting to discover that the tiles themselves were not made at De Jong’s, but were imported from as far as Belgium. Apparently, serial produced pressing of tiles remained far beyond the possibilities of a small pottery factory in Gouda. At the back, we often see an inscription like "MADE IN BELGIUM", a unmistaken proof of origin. The designs in a wide variety are devised in their own workshop. Initially, the Delft blue palette is still popular (Fig. 57). Although the design is painted by hand, it is applied to the tiles by means of a transfer. Such early designs still betray the hand of the painters who sat with De Jong in the painting room. Their style is characterized by a strong linear design in which text and image alternate. Especially the letters did not go too well for them, they are not written letters but drawn texts. It is clear that the painter could use a brush but could not really paint.

After a few years, the motifs are assembled with existing transfers that give a sort of collage effect lacking unity. In the meantime, the Delft blue pallet has been replaced by colour, although the result does not improve (Figs. 58, 59). The folklore images based on the Gouda souvenir iconography are primitive and amusing, but artistically extremely shabby. Yet collectors of today are tempted to find a complete series.

The poverty and simplicity of the workshop stays apparent in the product of the 1960s. After De Jong had press moulded the last clay pipe in 1959, they gradually started to liquidate the stocks. In an unpainted state the rather hard baked yellowish clay pipe of De Jong proved to be unsalable. Only the painted version has a certain market value. That painting starts on the current models (Fig. 60), then the pipes with broken off stems are being painted for souvenir purpose. During this period, the use of oil paint is exchanged for a turpentine-based paint. With the last products we see that the stems of the pipes have become extremely short (Fig. 61).

The second generation De Jong

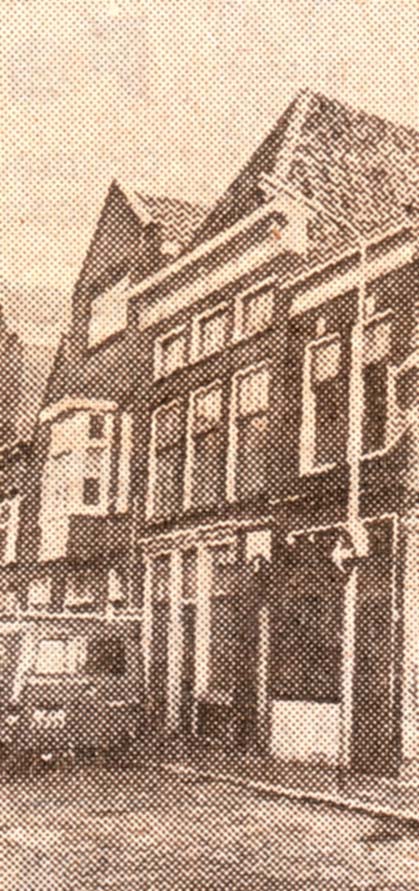

During all these years, the factory has been located on the Kleiweg, but the administration is carried out from home, as the heading on invoices with the mention Dutoitstraat explains. When Frank de Jong dies on 1 July 1965, this will change. In the same year, the factory moved from Kleiweg 42 to Wilhelminastraat 10 (Fig. 62). Son A.C. de Jong takes over the management. He is assisted by his sister who helps out painting the products. No pipes are made in the Wilhelminastraat at all; both the press moulded pipe and the product of liquid clay have disappeared. However, the sister paints for a few years on the old stock to make it saleable (Fig. 62). The last pipes are discoloured beaker shapes, which are given a solid brown or solid green paint and are sold with a red mouthpiece and a label from the 1930s (Fig. 63). Main customers for this stuff are the Gouda cigar shops De Herder, Jaske and Van Vreumingen who are still frequented by tourists.

In the 1970s I visited the factory several times. At that time, the production consisted mainly of all kinds of pottery. For example, Arie de Jong supplied ceramic pots, destined for petrol lamps painted in Art Nouveau style. Also meant for the semi antique market were the earthenware handles of brass peat bins that were extremely popular in the 1970’s interior. They were painted in Delft blue or polychrome palette with a few flowers. In addition, numerous souvenir items and small gift items were produced, such as ashtrays, mugs and more. All these products are produced into plaster moulds and fired in an electric kiln. The workshop gradually became an outdated workshop where brother and sister were mostly living from the sale of the stock, supplemented with an occasional small order.

When visiting the workshop, the most charming part was De Jong's office, which was located on the landing of the first floor of the building. The office itself was not much larger than one and a half meters square and consisted of a table with paperwork and some binders on shelves against the wall. Against the plank wall, on both sides of the door, there were two flat display cases, originally meant for the show collection of the factory. Gradually this became the private collection of the owner and over time the pipes for sale were exchanged for a weird collection of Gouda products from the end of the nineteenth century.

In 1977 it is time for liquidation. Arie de Jong has reached the age of retirement. The last stocks are sold out, often for discount prices. Within a few months, the inventory will be cleared away, most of the plaster moulds and biscuit products end up in the container. In that clearance two knee-pads emerge, once used by the pipe moulders. Economy and frugality went so far that, in addition to a strongly worn leather knee cap, even one was found back which was made of a car tire. It dated from the Second World War when leather was no longer available. These objects, together with some others, were selected to be included as a curiosity in a museum collection. With the closure of De Jong's factory, only Zenith remained as a pipe factory in Gouda. The Goedewaagen company had moved to Nieuw Buinen years before with the production of pipes.

Arie de Jong passed his old age in his house Onder de Boompjes. The two showcases with pipes were given a worthy place in the room of one of his fledged children. Here a small museum was set up as a memory of two generations of independence in pipes and ceramics (Fig. 64). He could look back on a laborious life in a small factory whose success lay in the poverty of the product, which was preferred by many consumer to the more expensive but high-quality factory products due to favourable pricing. A market segment characteristic of the crisis years, the time during and shortly after the Second World War and the fifties and sixties in which the eye for quality was still insufficiently developed.

© Don Duco, Pijpenkabinet Foundation, Amsterdam – the Netherlands, 1995.

Illustrations

- Frank de Jong as a young pipe maker in the workshop of the Firm P. Goedewaagen & Sons, Gouda, the Netherlands,1908.

Amsterdam, Pijpenkabinet collections Pk 235b

- Press mould made by Frank de Jong for the production of a souvenir skating pipe showing the head of a clown in a top hat. Gouda, Koninklijke Goedewaagen, 1922.

Amsterdam, Pijpenkabinet collections Pk 1.131

- Frank de Jong posing with the most prestigious bride grooms pipe of the Goedewaagen Factories, Gouda, 1931.

Amsterdam, Pijpenkabinet collections, documentation.

- Heel mark grid or nail top impressed on the bottom of a so-called doetel shape pipe bowl. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 28

- Stem label with text "DE JONG & CO. GOUDSCHE PIJP GOUDA". Gouda, De Jong’s Pijpenfabriek, 1934-1936.

Amsterdam, Pijpenkabinet collections, documentation.

- Stem label with text "DE ECHTE HERTEKOP PIJP". Gouda, De Jong’s Pijpenfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 5.088

- Label used on cardboard boxes for clay pipes. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1945.

Amsterdam, Pijpenkabinet collections Pk 6.954

- Clay tobacco pipe with the traditional oval bowl and shorter stem named halve lange (half long). The bowl mounted with a pipe cover of wrought metal thread. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 7.921

- The long and the short kantoorpijp with doetel bowl, straight stem and button mouthpiece. Round the stem a silver coloured label with the name of the factory. Gouda, De Jong’s Pijpenfabriek, 1945-1960.

Amsterdam, Pijpenkabinet collections Pk 5.068 and Pk 5.087

- Clay tobacco pipe with beaker shaped bowl, without heel and straight stem. Stem label in red. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 5.069

- Three clay tobacco pipes in shape derived from the so-called sport pipe in different finishing, the top one a normal smoke pipe, the two others as souvenir articles one with flower decoration and the other in the colours of the Dutch flag. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 3.825, Pk 5.073 and Pk 9.647

- Clay tobacco pipe decorated in relief with a basket motive, more a pipe for blowing soap bubbles than for a serious smoker. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1955-1960.

Amsterdam, Pijpenkabinet collections Pk 5.084

- Two cigar holders, the bowl the head of Mercury, one painted in the colours of the Dutch flag, the other the colours of the Gouda arms. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 29 and Pk 5.351

- Press mould for a clay pipe with shape named portorico including a button shaped heel and a straight or slightly bent stem with a mouthpiece on the end. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 5.101

- Cigare pipe with a six sided conical bowl over the surface decorated with lines. Gouda, De Jong’s Pijpenfabriek, 1938-1950.

Amsterdam, Pijpenkabinet collections Pk 410ab

- Unfinished pipe mould in brass for a cigar holder with a conical six sided shape. Gouda, De Jong’s Pijpenfabriek, c. 1938.

Amsterdam, Pijpenkabinet collections Pk 5.686

- A large bowled pipe named Goliath with rather shapeless bowl, heel and straight stem with button end. Gouda, De Jong's Pijpen- en Aardewerkfabriek, 1945-1960.

Amsterdam, Pijpenkabinet collections Pk 5.046ab

- Tobacco pipe with curved bowl decorated with buffalo horns and the letters “RAOB” as a symbol of an English society. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 5.085

- Two different RAOB-pipes by De Jong, the small difference caused by the reworking of the pipe mould that made the pipe slightly larger and the decoration a little bit different. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 5.045 and Pk 5.085

- Stub stemmed pipe with a billiard bowl mounted with a wooden mouthpiece from the First World-War period. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1940-1950.

Amsterdam, Pijpenkabinet collections Pk 5.269, Pk 5.270 and Pk 7.397

- Stub stemmed bowl painted in Delft blue showing a landscape with a wind mill, the pipe covered with yellowish lacquer. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1940-1950.

Amsterdam, Pijpenkabinet collections Pk 5.269

- Stub stemmed pipe bowl painted in colourful Delft palette showing a landscape with wind mill. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1940-1950.

Amsterdam, Pijpenkabinet collections Pk 5.270

- Stub stemmed pipe bowl painted in purple in the style of Delft with a sailing boat in a Dutch landscape. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1950.

Amsterdam, Pijpenkabinet collections Pk 7.397

- Tobacco pipe with a double twisted stem and a tobacco pipe with a single twisted stem, made respectively from a long and half long Gouda pipe. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1940-1950.

Amsterdam, Pijpenkabinet collections Pk 1.418 and Pk 5.618

- The cheroot holder and the cigarette pipe with single wounded stem. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 5.090 and Pk 5.091

- Three miniature pipes with twisted stems decorated with paint in the colours of the Dutch flag, or the Gouda city arms and in plain red with gold accents. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 1.100

- Three different miniature pipes by De Jong in two sizes with a flower drill on both sides of the bowl and on the stem. The black pipe is not black backed but painted black. The lowest is a so-called bullekopje, a miniature with a curved bowl. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 3.631

- Cardboard gift box of the De Jong Firm in which three decorated miniature pipes in red clay. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

Amsterdam, Pijpenkabinet collections Pk 2.436

- Small gift box in ivory paper containing six miniature pipes of the later period when only white pipes were in production. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1955-1965.

Amsterdam, Pijpenkabinet collections Pk 5.360

- Cardboard box for a gross of miniature pipes with on the lid in blue the gable of the Gouda town hall and the name of the factory. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 1.885

- Detail of a flower painting on one of the souvenir pipes of De Jong showing the loose way of painting. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 3.825

- Detail of a painting in black of a mill between green bush, the pipe finished with a yellowish lacquer, here on a doetel shaped pipe bowl. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 28

- The so-called Goliath shape with a painting of schematically depicted wind mill between green bushes. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 25b

- The Goliath shape with a transfer print showing the gable of the Gouda town hall, covered with yellow lacquer. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1955.

Amsterdam, Pijpenkabinet collections Pk 25a

- Two types of Goliath-pipes with painting and transfer on the large and not very harmonious shaped bowl. Gouda, De Jong’s Pijpenfabriek, 1935-1955.

Amsterdam, Pijpenkabinet collections Pk 25ab

- Detail of the pipe shape called Portorico with a transfer print of the gable of the Gouda town hall in two sizes, both covered with lacquer. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 15.455

- Clay tobacco pipes in the shape called Portorico with transfer prints and paintwork. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 5.786 and Pk 5.870

- Oval transfer print depicting the characteristic Gouda town hall on the side of a lacquered pipe with a twisted stem. The clay pipe was made by Goedewaagen in Gouda (shape number 448) and decorated by De Jong. Gouda, Koninklijke Goedewaagen, finished by De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 5.349

- Double wounded clay pipe from De Jong, the longest pipe from the assortment in souvenir finish and with a transfer print. Gouda, De Jong’s Pijpenfabriek, 1935-1940.

Amsterdam, Pijpenkabinet collections Pk 5.972a

- Clay pipe with a double twisted stem and print of a girl from Volendam in local dress, the bowl lacquered and the stem with paint. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

Amsterdam, Pijpenkabinet collections Pk 9.891

- Clay pipe with double twisted stem in colours of the Dutch flag. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

Amsterdam, Pijpenkabinet collections Pk 5.346

- Clay pipes with a single twisted stem painted in the colours of the Dutch flag, the pipe made by Goedewaagen (shape number 448) and painted by De Jong’s pipe factory, 1935-1950.

Amsterdam, Pijpenkabinet collections Pk 5.042

- Clay pipe for souvenir with a transfer of the Gouda town hall in its original box with glass lid. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1955-1965.

Amsterdam, Pijpenkabinet collections Pk 5.988

- Stub stemmed pipe bowl is slip cast technique with a Delft painting of a Dutch landscape with wind mill, covered with transparent glaze. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

Amsterdam, Pijpenkabinet collections Pk 5.933

- Mystery pipe with a shape named Prince Albert, painted by hand with a Dutch landscape with wind mill. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 8.429

- Mystery pipe with on the base of the bowl a swallow tail and a bowl hold by a human hand, both hand painted in Delft blue. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 1.849 and Pk 5.974

- Mystery pipe, so-called stiftje with cylindrical bowl and short straight stems decorated with all sorts of Delfts blue souvenir paintings. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1960-1970.

Amsterdam, Pijpenkabinet collections Pk 5.973 and Pk 9.131abc

- Mystery pipe with swallow tail base, on the bowl painted by hand a Dutch landscape. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1965-1970.

Amsterdam, Pijpenkabinet collections Pk 13.296

- The popular RAOB-pipe with a special order text related to the Gouda motoring club. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1955-1965.

Amsterdam, Pijpenkabinet collections Pk 8.080

- Cigarette holder shaped as a Dutch wooden shoe, painted in blue with a flower and the inscription “GOUDA”, on the other side an inscription erased by over paint. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1950-1960.

Amsterdam, Pijpenkabinet collections Pk 5.985 - Miniature pipe rack in heraldic shape with lacquer finish with a print of a girl under an umbrella near the sea side. Gouda, De Jong’s Pijpenfabriek, 1935-1945.

Amsterdam, Pijpenkabinet collections Pk 5.359 - Miniature pipe rack in heraldic shape with a hand painted decoration of the gable of the Gouda town hall. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

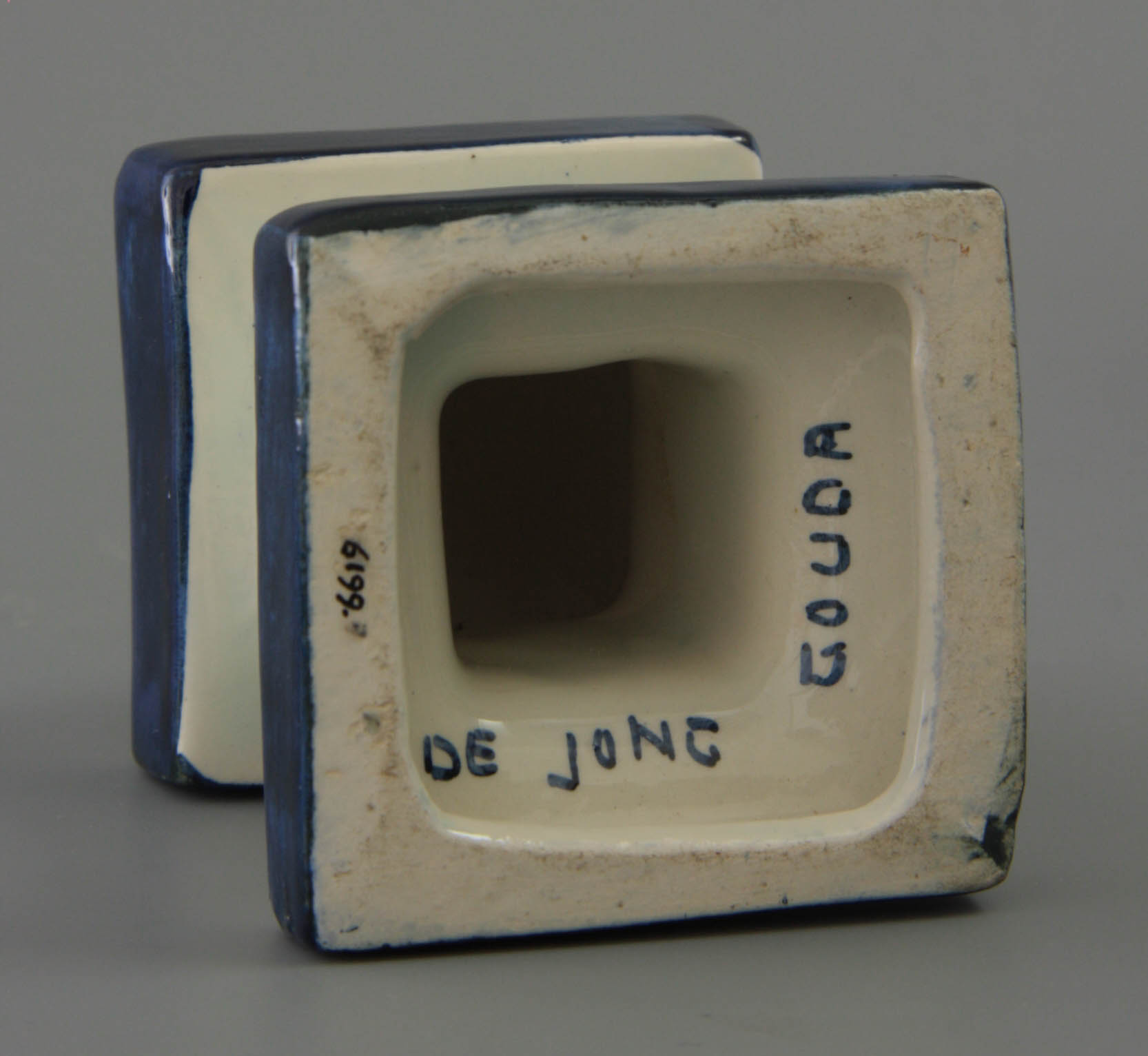

Amsterdam, Pijpenkabinet collections Pk 15.019 - Miniature pipe rack in polychrome in semi-Delft painting, on the reverse marked with the name of the factory. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1945-1955.

Amsterdam, Pijpenkabinet collections Pk 13.271 - Miniature pipe rack in Delft blue inspired on an example by the Royal Goedewaagen, on the reverse the signature of the factory. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1960-1965.

Amsterdam, Pijpenkabinet collections Pk 5.619 - Letter head of the factory De Jong’s Pijpen- en Aardewerkfabriek in Gouda, 1960-1965.

Amsterdam, Pijpenkabinet collections, documentation.

- Souvenir for a sport manifestation shaped like a mile stone painted with lettering. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1957.

Amsterdam, Pijpenkabinet collections Pk 6.199

- Wall tile to commemorate the Pijpensterrit, made in a Belgium factory and decorated in Gouda with a screen-print in Delft blue style. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1959.

Amsterdam, Pijpenkabinet collections Pk 15.325e

- Wall tile as a souvenir for the Pijpensterrit made up with all sorts of transfers with emblems related to Gouda. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1963.

Amsterdam, Pijpenkabinet collections Pk 15.325i

- Wall tile as souvenir for the Pijpensterrit decorated with a wide variety of modern prints of Gouda related subjects such as the emblem of the Moriaan Museum in Gouda. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1966.

Amsterdam, Pijpenkabinet collections Pk 15.325k

- Three long cigar holders with oval bowls, two painted with the Dutch flag and the gable of the Gouda town hall. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1955-1965.

Amsterdam, Pijpenkabinet collections Pk 31 and Pk 5.987

- Three short souvenir pipes from the large stock of broken pipes in the factory reserves, decorated in the 1970's in colourful paint to be sold in the Gouda souvenir shops. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1970-1977.

Amsterdam, Pijpenkabinet collections Pk 5.622, Pk 5.625 and Pk 5.626

- The building of the factory in the Wilhelminastreet in Gouda shortly before they closed down the business.

Amsterdam, Pijpenkabinet documentation, photo collection.

- Two beaker shaped pipes from the 1950's that were painted c. 1975 to look like briar pipes and marked on the stem with old labels from c. 1935. Gouda, De Jong’s Pijpen- en Aardewerkfabriek, 1974-1976.

Amsterdam, Pijpenkabinet collections Pk 7.848 and Pk 7.849

- Portrait of Arie de Jong with typical Gouda pipe in front of his private collection of clay tobacco pipes. Gouda, 1979.

Amsterdam, Pijpenkabinet documentation.

Litterature

A.C. de Jong, 'De Jong's pijpen- en aardewerkfabriek', Pijpelogische Kring Nederland, II-6, 1979, p 8-12.

Fred Tymstra, Catalogus De Jong's pijpen, Amsterdam, z.jr. (1977), 12 pag.

Notes

- Birth registers Gouda, 08-02-1888. Goedewaagen Archives 71, Pipemakers' book. Mentioned 1903-1906.

- Goedewaagen Archives 699, 08-05-1918. Certificate as ambulance-class. Elongated 13-05-1921. Goedewaagen Archives 1016, 17-05-1918. De Jong, fee for exam ambulance-class ƒ 10,-.

- Goedewaagen Archives 1015, 27-01-1917. Frank de Jong, mould maker, weekly wages ƒ 16,- (first mentioning).

- Leiden, Pijpenkabinet collections Pk 1.131.

- D.H. Duco, Bronnen tot de geschiedenis van de pijpennijverheid in Gouda, Amsterdam, 1976 e.v. 30-05-1995 Chef Frank de Jong is mentioned in an interview with Alie van Dijk on the Koninklijke Goedewaagen.

- Goedewaagen Archives 1005, 28-02-1922. Month wages of F. de Jong, brass moulds, ƒ 190,-. Goedewaagen Archives 1005, 31-01-1923. Inspection for Direct Taxes Fr. de Jong, Bockenbergstraat 79, ƒ 2380,-.

- Anonymous, De Goudsche pijpen en het Goudsche aardewerk, een interessante fabricatie, Gouda, 1931.

- SAHM, Goedewaagen Archives, 01-12-1927. Anonymous letter to the director of the Goedewaagen Factories.

- Don Duco, Goudse pijpen, Amsterdam, 1978, p 36.

- Goedewaagen Archives 1030, 30-04-1934. Dismission, 2 monthes payed a total of ƒ 155,- (worked shorter) and ƒ 171,- = ƒ 326,-.

- D.H. Duco, Merken van Goudse pijpenmakers 1660-1940, Lochem, 1982, p 42.

- Don Duco, 'RAOB-pijpen', Pijpelijntjes, III-2, 1977, p 6.

- Don Duco, Goudse pijpen, Amsterdam, 1978, p 36.

- Adress book Gouda, 1950. De Jong's Pijpen- en Aardewerkfabriek, Dutoitstraat 5.

- Adress book Gouda, 1964. De Jong Pijpen- en Aardewerkfabriek, Kleiweg 42.

- Amsterdam, Pijpenkabinet collections, Pk 1.878 and Pk 2.889.