The revolution of the system pipe

Auteur:

Don Duco

Original Title:

De revolutie van de systeempijp

Année de publication:

2006

Éditeur:

Pijpenkabinet Foundation

Description :

Historical overview of the tobacco pipe with metal frame stem and comparative systems from the beginning in the 1930's to the 21st century, including all kinds of alternative designs.

From the middle of the nineteenth century, tobacco blends were spiced up with additional flavours and so many new tobacco tastes came on the market. Many smokers became gradually more interested in the flavoured tobaccos, a more intense aroma but which also poses a downside. Flavoured tobaccos are significantly more humid so that condensation in the stem of the pipe may occur which makes smoking less pleasurable.

Pipe manufacturers tried to combat the moisture problem and create systems to get rid of the condensation and moisture. Numerous of such attempts are known, ranging from simple porous nicotine stones to condense rooms, moisture locks, drainage tubes and so on. Bringing a system in pipes can be seen in all conceivable materials. This applies even to the traditional genre such as the clay pipe and meerschaum pipe, both materials that are naturally porous and moisture absorbent. More often it is applied in the briar pipe that absorbs less moisture and thus results in a wetter smoke.

From 1880, dozens of patents for inventions were granted in which new dehumidification of smoke and the disposal of condensate are described and protected. Most of these inventions are ingeniously devised but had a short life, while a large proportion of patents never even went into production. They are often too complicated to construct and too little effective in use, mainly because they were for the smoker impractical to clean.

Many inventions are based on a similar principle: the use of two different materials which stimulate condensation, possibly in combination with a storage place for moist. Especially with briar pipes the metal parts stimulates the condensation of moisture from the smoke. From this principle the metal insert in the stem is applied which is based on a physics: rain that leaves a cloud at the time that a cloud of cool air is encountered. Filters, plugs and spirals in all shapes and designs mark the beginning of an entirely new principle where the wooden stem is exchanged for a metal. Of course this is only possible when lightweight metals come on the market and that happened in the thirties of the last century.

American roots

Entirely fitting in The Early Machine Age, from 1930 aluminium entered in the pipe industry. Aluminium has qualities that are important for the pipe: the metal absorbs the heat well, while it is light in weight and therefore pleasant in use. In addition, aluminium has a modern and hygienic look that suits the type of smoker that was after a modern and comfortable smoke instrument. It is therefore not surprising that in the thirties pipes were made having aluminium parts. The stem is the element of choice that can easily be made of metal. The briar pipe bowl and vulcanite mouthpiece are obviously not suitable to be replaced by metal. Aluminium stimulates the condensation of the moisture from the smoke, and at the same time can house a fluid reservoir.

As is often the case, such findings happen in several places more or less simultaneously. The starting point is always a metal part that offers condenses the opportunity to precipitate and that houses a drainage system. These modernist so-called system pipes were conceived in various U.S. states with as a fundamental principle a pipe of briar and a stem of aluminium with the usual mouthpiece of vulcanized rubber. The metal parts were often made in companies that serve the emerging aircraft industry.

One of the earliest inventions that acquired great popularity, was the Kirsten pipe (Fig. 1a-f). This product attaches the briar pipe bowl to a stem with a screw system. The stem has a design based on the principle of the radiator and is even referred to as radiator. The surface is enlarged by curves, so that it can give up the heat quickly. The square section of the stem provides a modern look that gives the pipe a timely appearance. In the hollow stem a genius system is devised: the smoke goes in a tube, the so-called dry-drawn tube and made a long way for better cooling. The condensation is collected in the metal stem and with the aid of a circular stopper at the end the undesirable moisture can be removed after smoking.

The pipe has an ingenious addition that completely fits into the hygienic thinking of that period. With a small stopper at the end of the stem, the connection between the bowl the stem can be closed. Kirsten advises to do this if the pipe is emptied to prevent the moisture to run back from the stem into the pipe bowl hence the flavour of the tobacco will not be affected. In addition, when cleaning the pipe bowl the shaft space can be closed so that ash will not enter the stem. Even if the pipe is transported, the stop at the end of the pipe stem serves as seal.

The inventor of this extraordinary system was Frederick K. Kirsten, a German by birth who immigrated to the United States and eventually obtained a lectureship in Aeronautical Engineering. Early thirties when he was advised to stop smoking cigarettes, he started looking for a pipe without moisture problems and without tongue bite during the smoke. It soon became clear that such an article did not exist so he started to design his own. Besides the briar and rubber materials he used aluminium, which he knew well because of his profession. Characteristic for his invention is the synthesis between modern design, a high degree of comfort and attention to hygiene, three principles for the modern life of the thirties. For the production of the pipe, the Kirsten Pipe Company Inc. was founded, based in Seattle in Washington State. The firm was founded in 1936 and would have a long existence.

When the pipe soon became popular among the smokers new bowl types appeared, while, in addition to a straight pipe shape also a half bent and a fully bent shape were designed. When this range of models is available Kirsten offered an additional advantage. As a smoker, you can compose your own pipe by selecting the shape of the stem, choosing the colour or go for a particular size, design and finish of the bowl. The white metal version soon is the most popular and was named Mariner, the black powder coated was called Lancer and the golden version got the is name Jewel. Besides advantages, the Kirsten pipe also has disadvantages: the pipe had a massive appearance and a relatively large weight. Especially the straight shape provided a strong leverage which is not always comfortable when smoked between the teeth.

It is good to know that Kirsten was not the only firm that worked out a particular tobacco pipe. More or less simultaneously, different designs were created, all of which emanate from the same basic principles: a synthesis of three materials, a removable bowl and maximum attention to cooling and moisture removal. Presumably it will be the marketing and pricing that one species is caught on, while the other disappeared from the market after a short period. Besides a bowl in briar, also meerschaum or even corncob was used, always with the same screw system.

A well known American imitation of the Kirsten pipe is the Bryson (Fig. 2a-e) manufactured by the Briarwood Corporation in Palo Alto in California. Surprisingly, these bowls were not made of tuned briar but of crushed briarwood compressed under extremely high pressure without any glue. The company advertises that this method creates a perfect imitation-briar with increased porosity. On the outside, the compressed substance is finished with dark paint with a imitation wood grain. Less successful is the lacquer that must guard the bowl for wear. On this product the briar is attached with a crosshead screw to the stem, which is made of polished duraluminium with a hexagonal diameter. The stem promotes an additional cooling because therein a tube has been placed that is attached to the screw-button at the end of the stem. This tube has an air hole close to the mouthpiece through which the smoke is forced to go a long way, so that it cools more.

The Bryson design comes from Max Bressler from Chicago, Illinois and dates from around 1940. Also for this system pipe several patents were issued, but the actual pipe is not available according to magazine campaigns before the year 1946. When buying a Bryson the consumer was presented two bowls: a smooth model and a rusticated one.

Another imitation of the Kirsten pipe was invented by Frank Mariani, which was patented in 1941. A curious variant is the Ashcraft, which appeared more or less simultaneously on the market. Here the system is revolutionary: a metal inner and outer bowl were used which do not touch. While smoking, the inner bowl absorbs the heat while the outer bowl remains cool ensuring a comfortable handling of the pipe. The inner bowl can easily be removed for cleaning. The disadvantage is that the bowl itself does not absorb moisture while the metal is not so insulating in comparison to briar. This means the smoker looses fire quicker.

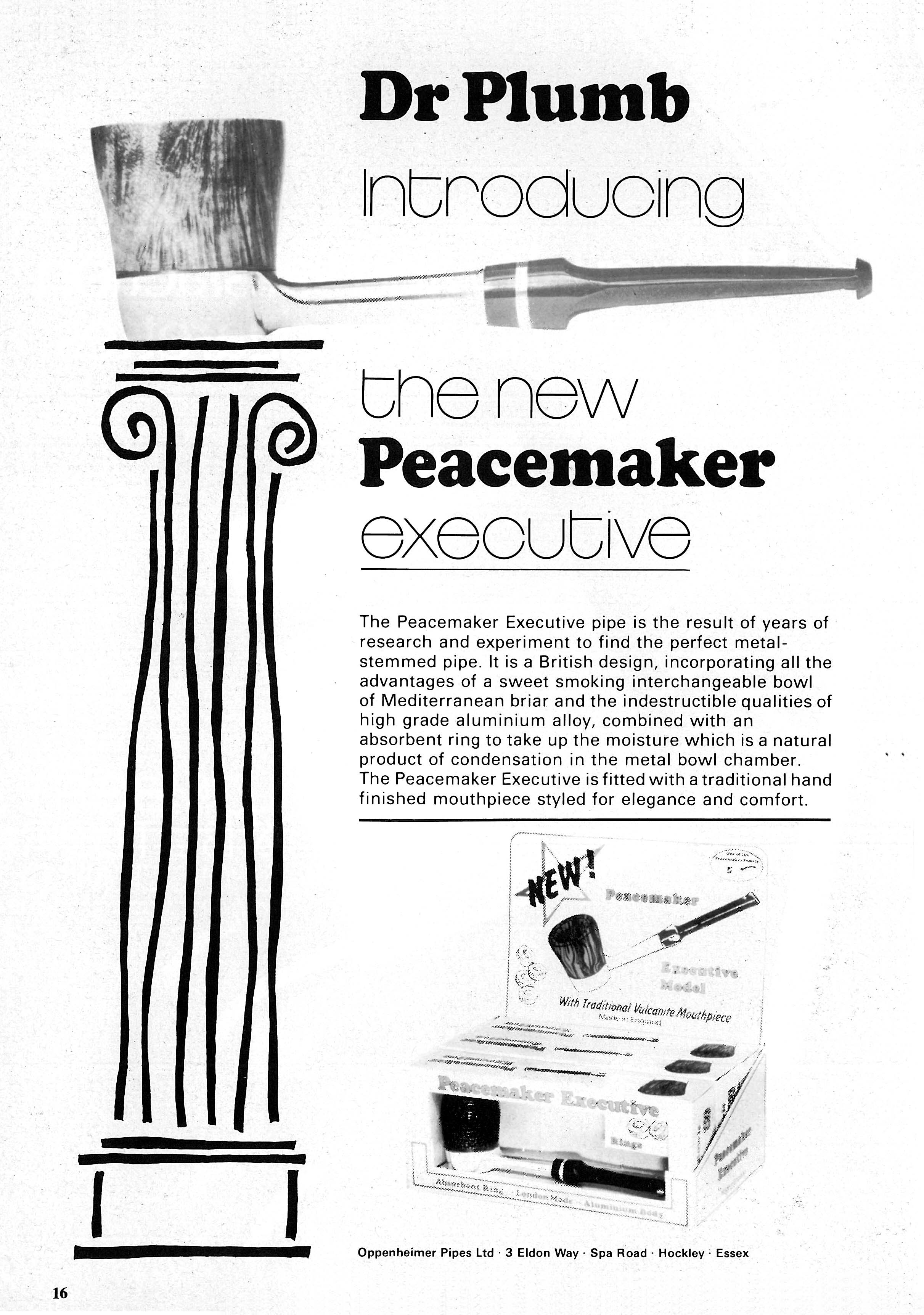

Falcon as a brand

As noted, there is no invention that comes alone: a new thought always arises in multiple places simultaneously. Witness the design of Kenly Bugg, an engineer from Fort Wayne in Indiana. In 1936 he invented the Falcon system pipe which is very similar to the Kirsten, but differs in some aspects. The success of the Falcon, a design that since that time gained a respectable place in the world of pipes, will definitely bring a revolution among pipe smokers.

The Falcon pipe is based on engineering rather than it arises from the idea of designing a traditional tobacco pipe. Again the pipe consists of two opposing materials, one warm the other cool. The bowl of the pipe is of briar wood, whilst for the stem aluminium is chosen. Both elements are joined by means of a screw thread.

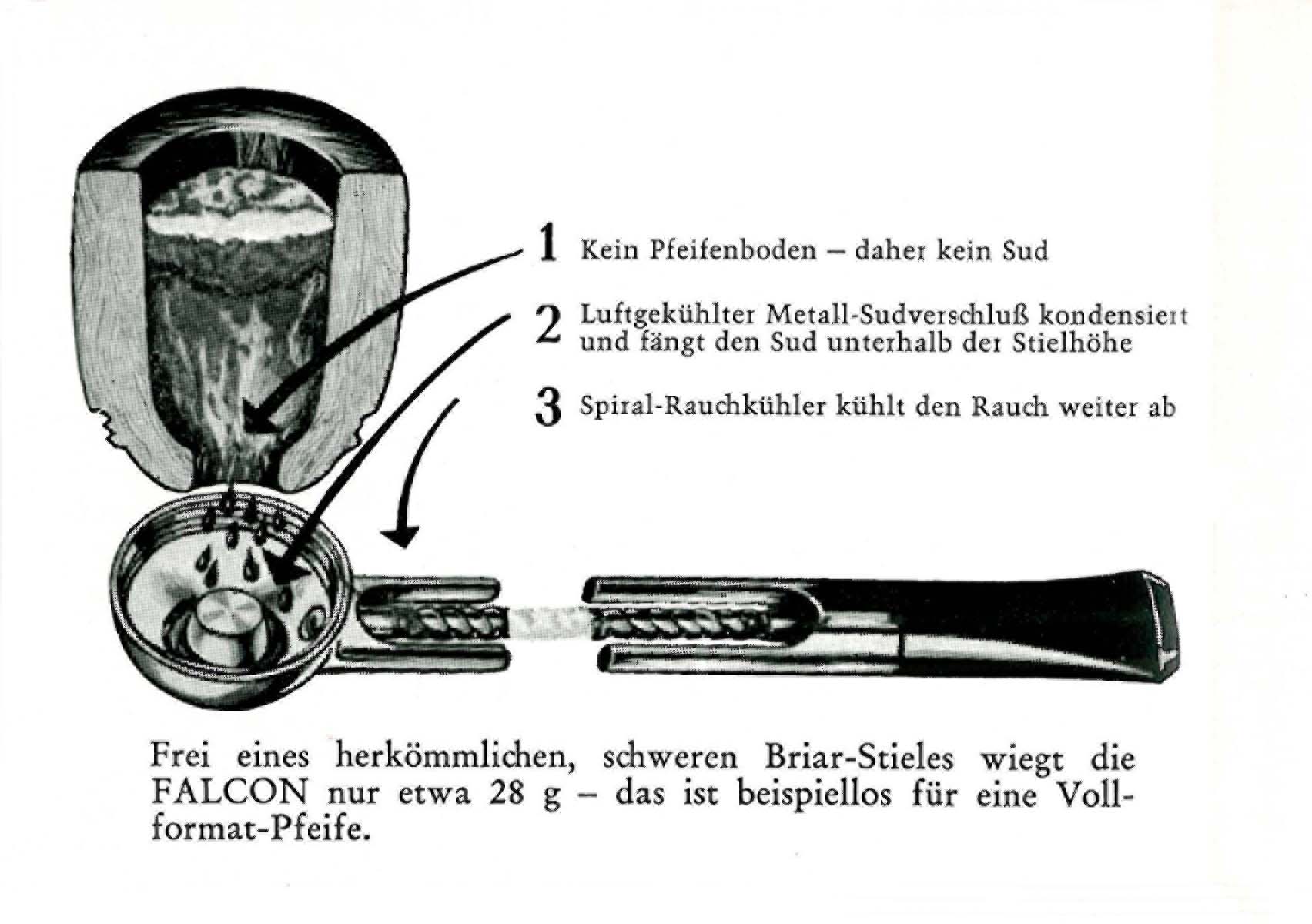

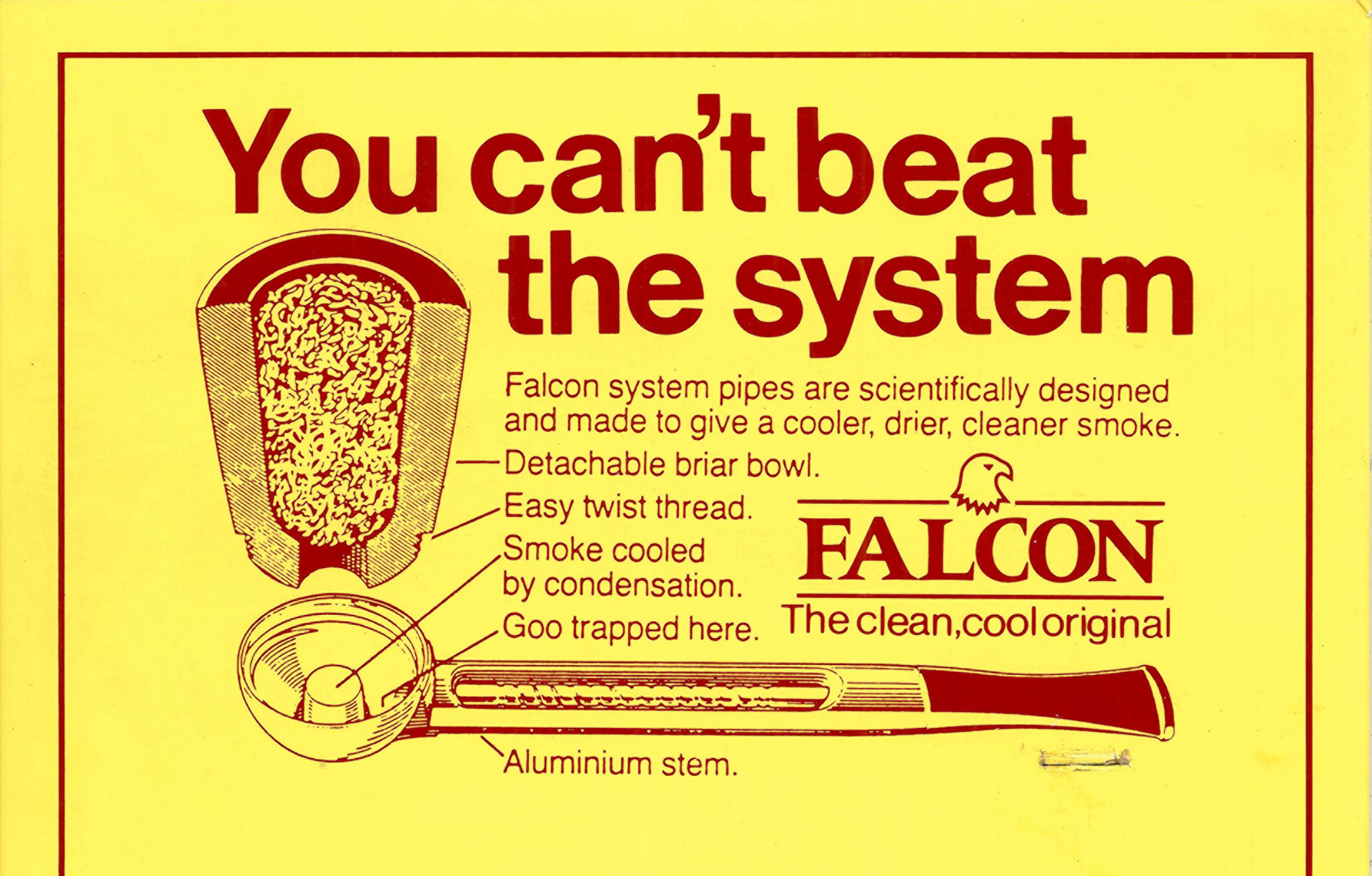

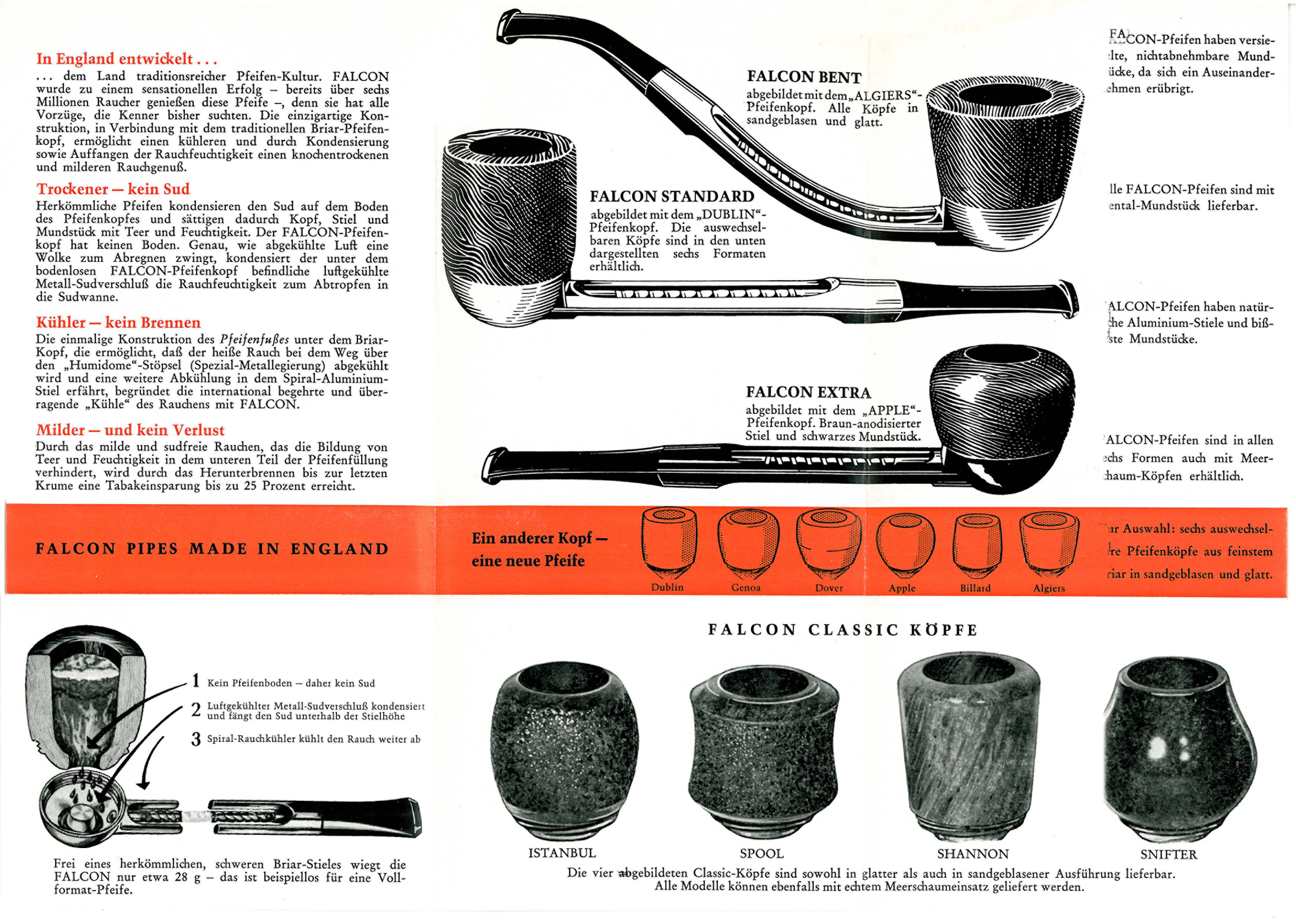

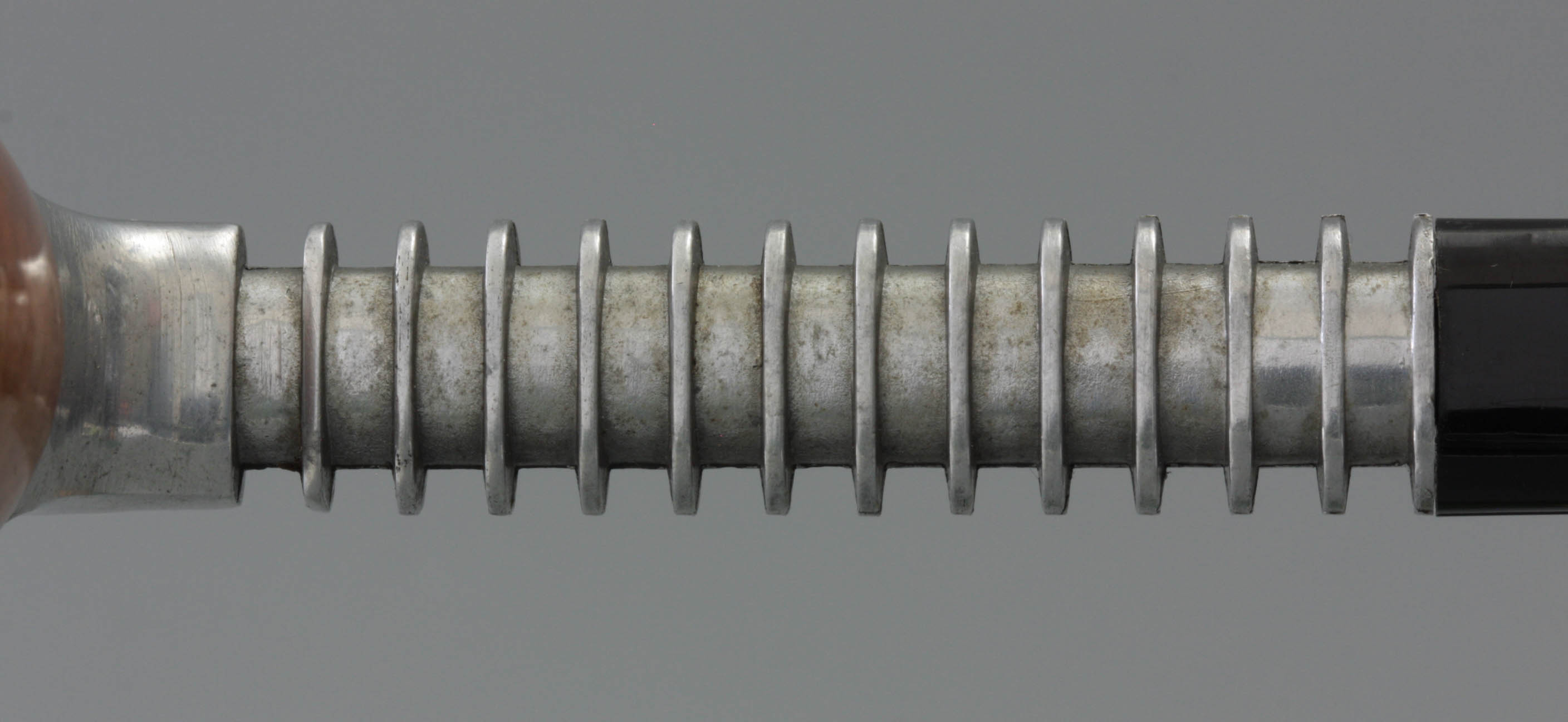

In contrast to the Kirsten pipe the Falcon has a light weight metal stem in which the cooling is mainly based on release of heat, instead of taking it in. The spiral-shaped tube, which forms the smoke tube is placed in a frame in the stem and provides rapid absorption of heat and quick release as well. This results in cool smoke. At the same time the transition from the wooden bowl to the metal base causes a so-called thermal bridge, whereby the moisture from the smoke condenses at this very place, and precipitate. This condensation is further supported by the bottom of the bowl that has a cylindrical aluminium plug with a lens-shaped upper side (Fig. 4e). Very appropriate, this element is called condensor or humidome and this metal base ensures condensation on the metal bottom of the pipe, later easily to be removed from this space under the bowl. In this metal base, a cloth filter called the dry ring is placed (Fig. 3b) that purifies the passing smoke of flying ash and tar particles and at the same time absorbs the moist.

Extremely practical is that the briar bowl of the pipe can easily be removed because it is fitted wit screw thread having four starting points, and thus the bowl can be retrieved by twisting it only a quarter. With a single click the bowl can be removed for cleaning the base with a tissue and after the treatment the bowl can be clicked back. A diagram from one of the promotional leaflets clearly shows the system (Fig. 3a).

Looking at the construction of the pipe in detail it is obvious that the design is not related to the mainstream of wooden pipes with a system and was passed over to the brain of an engineer. The stem with aluminium bowl holder is made in a meticulous manner and the quality can be compared with high grade castings for the aerospace industry. This frame is especially difficult to make, because it contains a screw thread with four starting points. The profile and tolerance of the thread should be monitored carefully, because if it does not close optimal the pipe starts leaking which results in nicotine stains and false draft.

In America, the Falcon appeared on the market in 1940 and was received by many smokers with great enthusiasm. However, because the Second World War there soon is a restriction on the use of aluminium. The manufacturer has to cease the regular supply of these pipes and only sales to the U.S. Armed Forces may continue. However, after the war the production of the system pipe was taken up again and on 21 August 1945 the patent was obtained.

In 1949 the marketing of the Falcon was taken over by George Hunt (1908-1981) of the Diversey Machine Works Co. in Chicago (note 1). The company D.M.W. specialized in aluminium products for the aviation industry that were made with great precision. After the Second World War Hunt became the sole owner. Besides pipes he also made the famous ball pen named Rollit.

Sales of the Falcon is strongly promoted by Hunt with an advertisement campaign. One of the slogans of that period is: The World's First Perfect Tar-Free Air-Cooled Pipe. For retail, a display card was offered with three pipes. Still, sales in the first years were confined to only four states: Indiana, Michigan, Illinois and Iowa. Then the sales network is expanded although it takes until 1954 before the Falcon pipe is available in all the states. The sale result seem overwhelming and the turnover grew steadily. By 1954 already six million Falcon pipes were sold (note 2). The biggest revolution in pipe smoking was realized. Meanwhile, the patent for this product was secured for all states of America by 1956. More or less simultaneously the factory moved from the Van Buren Street to a much larger complex on Kilpatrick Avenue in Chicago where the production was done on a larger scale.

The English production

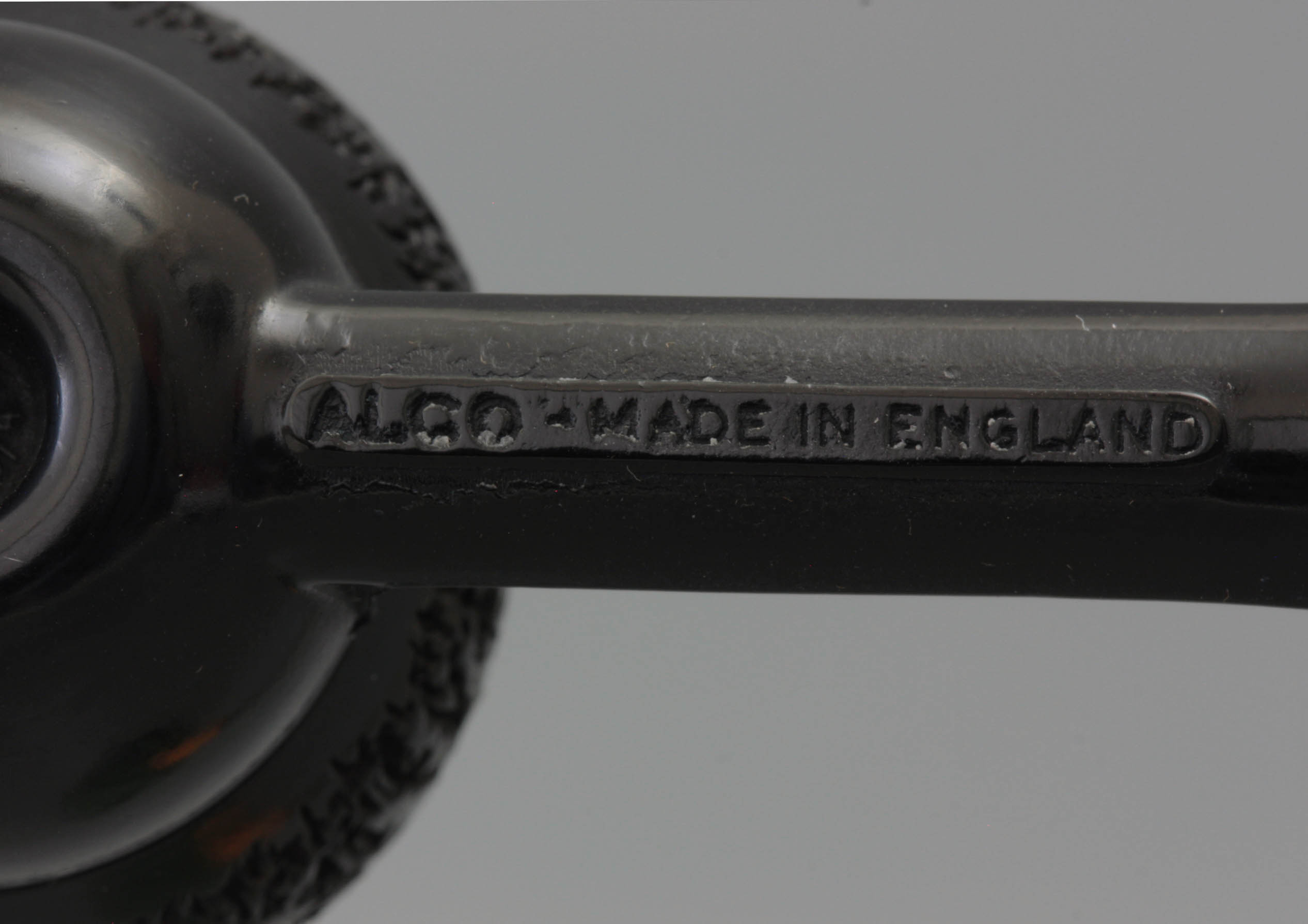

The unprecedented success of the system pipe in general and the Falcon pipe in particular was experienced by every U.S. smoker. Curiously, however, this revolution was not recognised in Europe. Not as early as 1956 a man named David Morris, director of the large tobacco chain A. Lewis Ltd. became aware of the success of the Falcon during his visit to the United States. Morris negotiated with Hunt as director of the American factory and decided to spread 10,000 Falcon pipes over the 350 warehouses of Morris to see if the sale in England would be successful. The first shipment of 333 sets of three pipes was sent in December 1955. Soon Falcon was faced with a dispute with the pipe factory Comoy that already used the brand name Falcon which they suddenly claimed. In order to avoid problems the mark in the cast metal stems was altered: the first and the last letter were removed, so that the mark changed from Falcon in Alco. Fortunately, the aluminium was sufficiently thick enough to made the manoeuvre possible while completely removing the text would have weakened the pipe. A second shipment is named Rollit, after the ball pen produced by Hunt. Shortly afterwards the problem with the trade mark was solved between the two firms and the mark Falcon could be used freely.

Convinced of the market opportunities for the Falcon Pipe in England Morris negotiated further and soon he got the rights for the production outside the United States and above that the worldwide sales in both cases with the exception of America. Shortly thereafter, he founded two companies: Falcon Pipes Ltd. for the production and Falcon pipes Distributors Ltd.. for the sale and distribution, both based in London.

The British factory proved not so quick in its start. Before the machines for the metal parts were transported from Chicago and were functional for production and also the required quantities of briar bowls were available two years passed. In October 1958, the first English Falcon pipes were sent to the U.S. headquarters for approval and production could start. Before Christmas 1958 the first 30,000 Falcon pipes were ready for shipment and this quantity was immediately taken by the retailers. In the same year already fifty persons were employed at Falcon England (note 3).

In England the Falcon pipe quickly gained interest and in Spring 1960, the demand had grown so large that the London factory needed to look for production expansion (note 4). Already in Spring 1961 a new factory in Shepherds Bush in London was occupied with an available floor capacity of almost five hundred square meters. Now the production was fully automated and realized some 10,000 pipes per week. To ensure the quality of the Falcon Pipe specialized machines were developed and thanks to new investments half a year later, the production could be increased with fifty percent.

Meanwhile, the Falcon pipe had become a renowned and much sought after product. To ensure maximum quality the factory developed special machines to test the stems. After production, each pipe was checked for optimum throughput smoke, but also whether the pipe was completely free of false draft. When the demand continued to increase in the Summer of 1962 it was decided to proceed in even larger production units. As a result, in February 1963 the factory moved again, this time to Brentford in Middlesex, where a production of no less than 20,000 pipes per week could be realized. The logistics of this move and to continue the production volume and quality had been a huge operation, which the company successfully passed (note 5).

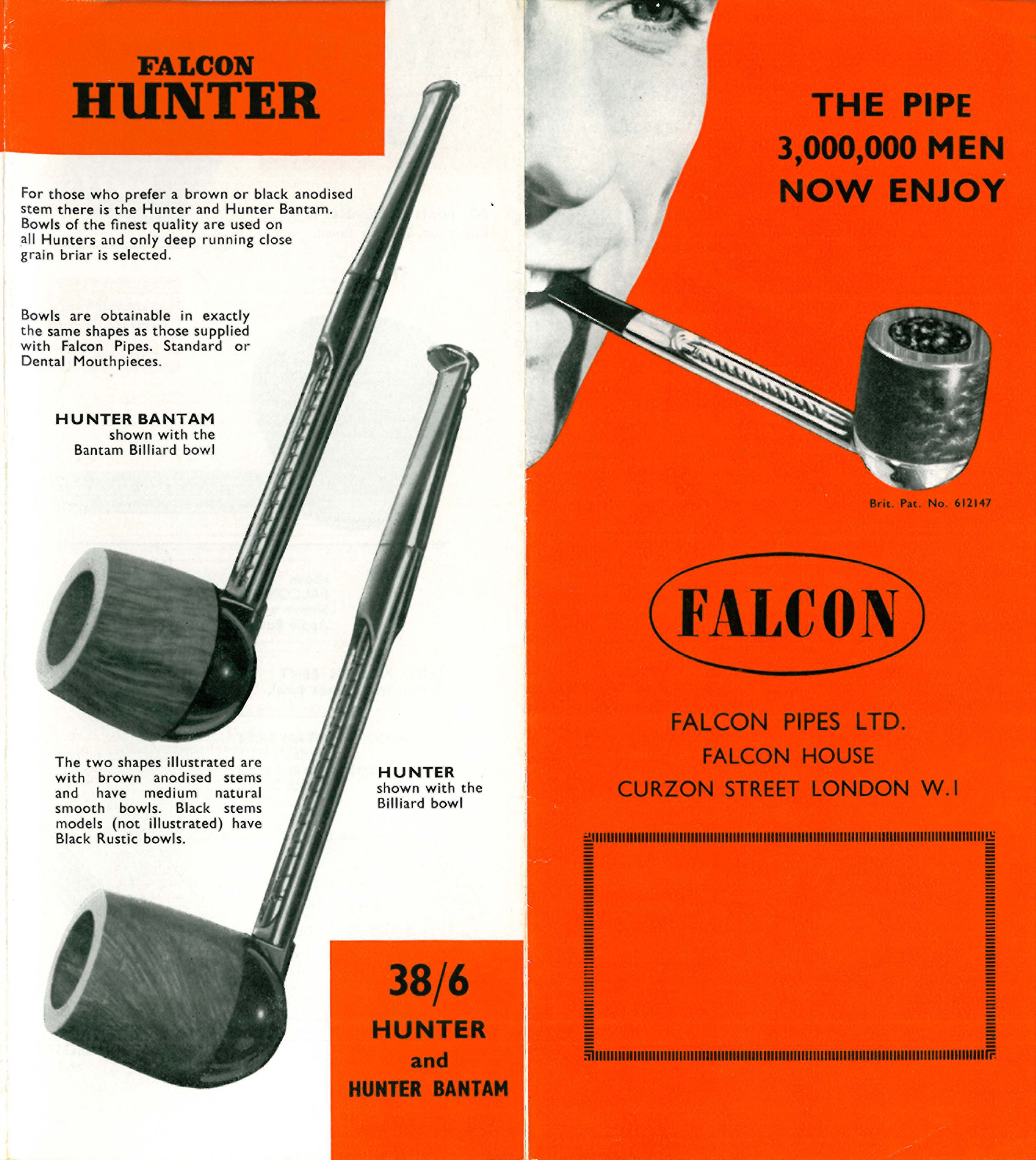

The appearance of the Falcon pipe with its white aluminium stem, dark bowl and black mouthpiece was for the 1950's a most modern experience. For the more conservative smoker the shining white metal was, however, too striking. Spraying or coating of aluminium was at that time still a problem. Initially it was thought that it would be impossible to create a strong, durable anodized finish on the pipe, but also with this the Falcon factory succeeded after a long period of experimentation. Around 1954, also black and dark brown system pipes were delivered, which have a greater resemblance to the traditional briar pipe. The brown version received the sportive name Hunter and was often fitted with a light brown bowl. The Hunter is launched in 1956 and the first 30,000 copies were quickly sold thanks to an extensive advertising campaign.

Apart from the stems also to the other parts of the pipe maximum attention was paid. For example, the mouthpiece was made from a special type of nylon, which is particularly strong and guarantees a long life. The manufacturer advertises that the mouthpieces can even withstand the sharpest teeth. Unlike all other pipes, the mouthpiece is glued to the metal stem. To prevent the consumer to force the mouthpiece, it is noted on the plastic cover that it should not be removed (Fig. 5c).

Of course the briar bowl is the most important part of the pipe. That the choice is for briar wood speaks for itself. The bowls are turned of good quality briar of which the ebauchons were specially ordered. Naturally, the briar blocks are significantly smaller than the wood of the ordinary tobacco pipe which is advantageous for the purchase. A lot of research was done to carry out the turning of the bowl entirely mechanically, again with a high degree of standardization. After bringing the bowl to the desired shape, also a rustification is applied by machine. At last the making of the quadruple thread end into the base is done, a painstaking piece of craftsmanship.

For the bowl shapes three types of names were chosen. The first refers to the classical models such as bulldog, billiard, apple and so on. Also numerous proprietary designs with names of towns or country areas were created, including Dover, Plymouth, Genoa, Istanbul and Algiers. Some models with bizarre geometric shapes are the hyperbole and the snifter. In terms of colour the polished bowls vary from light to dark but can also be reddish. For the rusticated bowls briar of less quality was used. A luxurious series of pipe bowls are lined on the inside with meerschaum.

Of course, a modern product needs to be delivered in the most hygienic way. The manufacturer also pays much attention to the cleaning and purging of the product. This cleaning works on ultrasonic sound waves so that it is certain that every speck of dust no matter how small was removed. The product was then packaged in a modern box showing as brand the head of an eagle. The same logo is also applied in white at the top of the stem (Fig. 4d). The protective cover round the mouthpiece has already been mentioned.

After several years of successful production, the range of products was expanded. In 1963 the factory launched the Falcon Extra. The Bantam of Oxford series show a modified concept with a stem that is ten percent shorter, while also smaller bowls became available. Of course, these bowls were compatible with the larger sizes analogously to the standardized method of the factory. The principle of interchangeable parts, remained of course one of the strengths of the product. Once this system was chosen by the smoker it was not inviting to switch to another brand.

In 1964, the brand name Alco was introduced as a second brand (Fig. 5a-d). The name Alco was already used in 1955 as a temporary stopgap. Now the factory destined this brand name for a specific line of Falcon of which only the shape of the stem is different. The frame stem of the Falcon is in the Alco replaced for a more massive but thin multi-sided stem. The obtained result is surprisingly sporty. Furthermore, the pipe is the same: the bowl is removable and has the same ingenious four-in-a-thread. Unexpected is that unlike its smaller size, the bowls were not interchangeable with the Falcon. The mouthpiece is again made of black nylon. Besides a brown version also a Bordeaux red type was marketed. The mark of the eagle's head is posted on a globe for the Alco pipes, a most appropriate addition to a brand that was worldwide known by that moment (Fig. 5c).

Also in the second half of the sixties new products were introduced. In 1965 The Pipe is introduced with new materials. For this article the smoking public showed no interest at all. Two years later the Brentford Pipe appeared, with an angular stem, sloping on the sides. Also, this product was not very successful and disappeared from the market in 1979. Both innovations prove that the pipe smoker was very satisfied with the Falcon and was not looking for a replacement by a new product.

From the time of the great success also dates a special advertisement campaign. At the instigation of the Falcon factory a certain Charles Graves published a general book about pipe smoking. It appeared in 1969 under the title "A Pipe Smoker's Guide" and was full of interesting facts for pipe smokers. Curiously, an important part of the content consists of the history of the Falcon dry smoker. This places the product very prominent in the history of the tobacco pipe. To complete the publication we find in the back the names of the Falcon dealers from all parts of the world. Considering that about twenty percent of the publication is dedicated to the Falcon Pipe, the book contains a very misleading and biased information for the pipe smoker at that time. A striking feature is the frontispiece with a beautiful historicizing print of a smoker with a true Falcon Pipe between the lips. Of course the image leaves nothing to the imagination, the text clarifies "Shown smoking a Falcon Pipe".

By the end of the 1960s, the Falcon pipe was available in almost all corners of the world. The British factory exported about forty percent of its total production to 70 countries. A great success was Falcon in Australia, where it became the best selling pipe in that country only two years after the first imports. In Europe, the Falcon was popular in the Netherlands, France, Germany and Switzerland, but the pipe was also sold in the Middle East, Gibraltar, Malta and Cyprus, Mauritius and New Zealand. Even in South Africa and Ethiopia the Falcon Pipe was available. The success of the British factory exceeds that of the original U.S. company and by 1970 seven million Falcon Pipes were sold, excluding the same number produced in the United States.

Although the English and American Falcon pipes are identical, the English version was technically much better. For that reason, the English factory decided to take over the production of Falcon International Incorporated in Chicago from 1968. With this merger an end comes to three producing countries: the United States, England and Ireland. In the latter country the Falcon had been produced for some time, when the English factory could not meet the high demand, but production in Ireland was later discontinued.

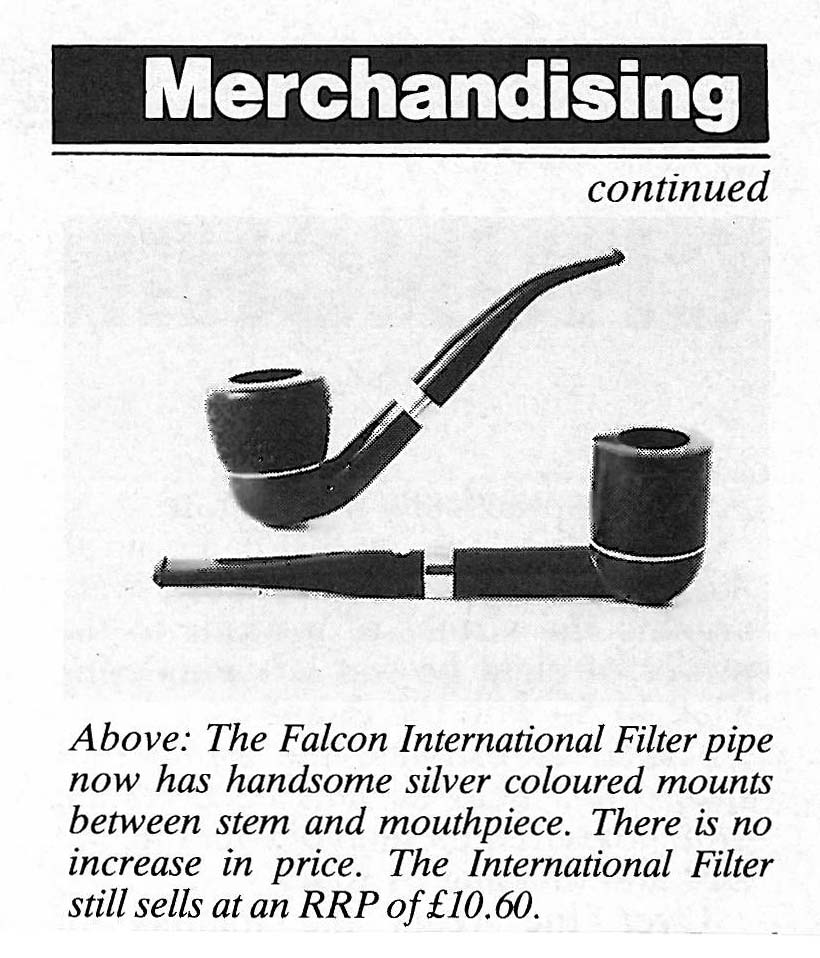

The closure of the American factory came on the right moment. In England, interest in the Falcon started to decline. By acquiring the American production the factory in Brentford could fulfil its production capacity again. When after 1975 the sale of Falcon pipes took a downturn, the factory came with some innovations. In 1977, it launched the Falcon International filter pipe, a pipe with a removable mouthpiece in which a filter could be placed (Fig. 6a-c). During that period the filter was emerging from the health thought that the smoke should be purified of tar and nicotine. In this pipe, the aluminium was coated with a specially developed finish, that improves the cooling down.

Two years later, in 1979, the Alco Universal Filter Pipe arrived on the market, especially for the younger starting pipe smoker. This pipe also got another mouthpiece with a groove that gave more comfortable grip. The launch of a filter pipe fits in the general prevailing interest in cleaner smoke. Again it turned out to be a temporary product that did not last.

In the 1980s Falcon introduced an additional curved model (Fig. 4c). The next arrival on the market was the Universal Gold, a colour pipe with an elegant gold band. New is also the removable mouthpiece in which the smoker could insert a Falcon filter. The luxury of the pipe was also emphasized by the choice of seven gold-coloured bowls which were lined on the inside with meerschaum. The product became a luxury gift item but again the sales remained limited and it became clear that Falcon was servings a declining market. In the years that followed the production ran further back.

Already around 1970 a series of transfers of the factory started. Owners were the London and Midlands Industrials Group, the Williams Group and others. The company seemed constantly for sale, although it never changed the product. In 1993, the Falcon factory finally was sold to Merton of London, a firm which also represented several other pipe brands in Britain (note 6). The company name was changed to Merton & Falcon Ltd. The production continued although innovation of the Falcon system pipe no longer took place. In fact, the boom of the past was over and the manufacturer of system pipes did not manage to find new markets, the pipe became increasingly dated. By reducing the production rate the price of the Falcon went up but the pipe did not look like a luxury dry smoker. Hardly any marketing was done, the product focused on the loyalty of the remaining customer that was not prepared to try another brand of pipe.

American counterparts of the Falcon

Patented or not, the system of Falcon pipe inspired numerous pipe makers to give their views and profit of the sales successes. Especially after the expiration of U.S. patent other pipe makers launched their own system pipe. Most of the makers however, lose the fight with Falcon for the Falcon brand is unsurpassed and the smoker prefers a perfect pipe above an instrument with an innovative or creative design but with technical defects such as leaking.

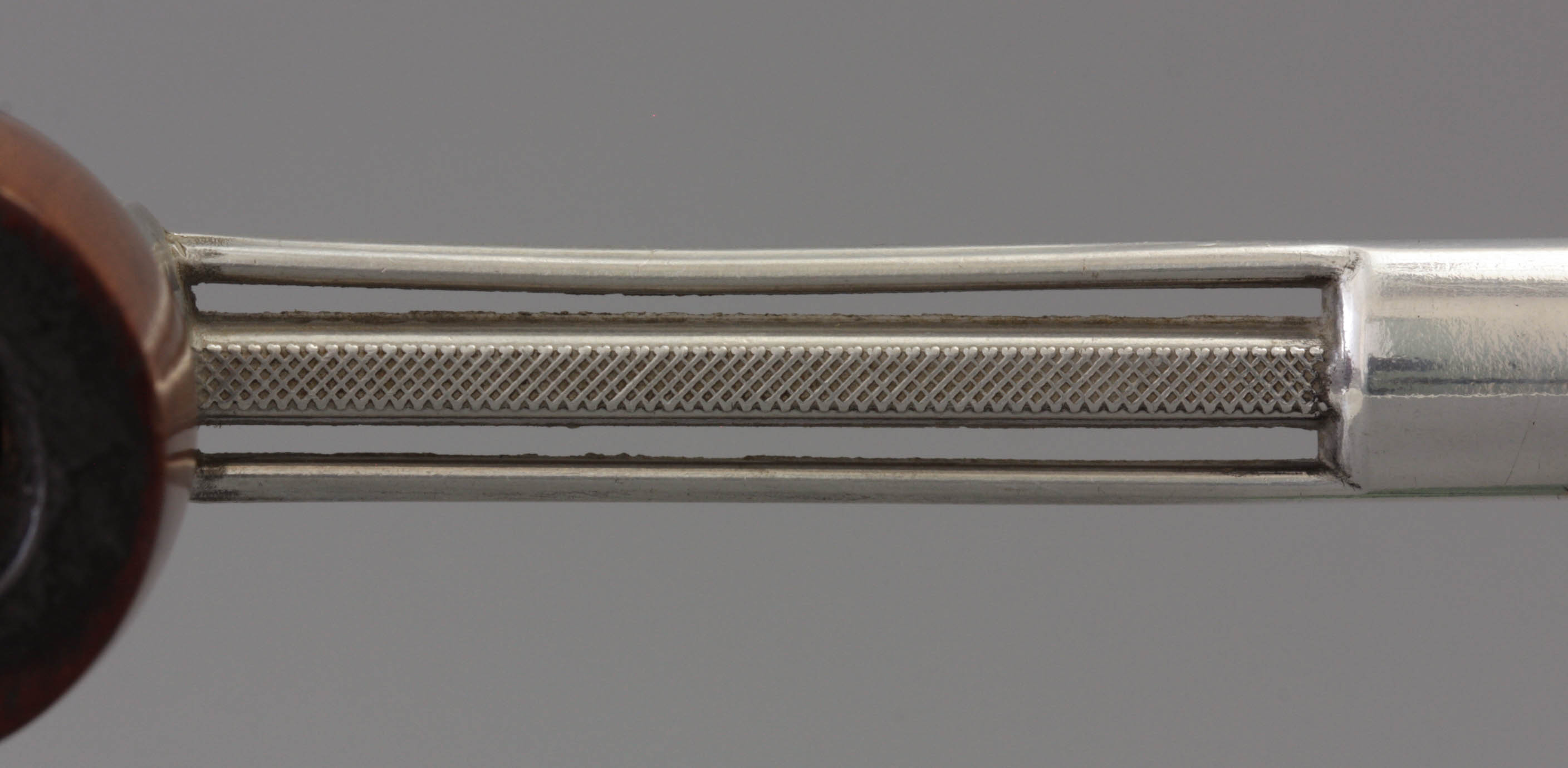

The oldest imitations of the Falcon were born in the United States, which is not surprising, because here the development of the system pipe was far ahead. A worthy second name is Dr. Grabow Viking (Fig. 7a-e), whose history is almost as long as that of Falcon. The earliest Viking was in fact already patented in March 1954 and thereafter several additional patents for improvements were issued. A man called Linkman from Racine in the state of Chicago was the inventor. The name for this system pipe was taken from a doctor friend that gave him the permission to use his name as a trademark for his tobacco pipe. His premise was that a physician's name without doubt would cause a positive effect on the marketing, especially in a time when the first anti-smoking idea took place. In appearance, the Grabow pipes resembled the Falcon, though differences of detail are visible. The main difference is the stem that does not consist of a frame, between which a spiral-shaped tube is inserted, but is strong and flattened on the upper side having upright cooling ribs. Thanks to the popularity of the Grabow pipe design almost as much variants exist as of the Falcon. Drawback is clearly the inferior quality of the metal part, of which the thin lacquer layer on the outside peels of after a period of time. Moreover, the Viking pipe is heavier.

An American system pipe derived from the popular corn cob pipe is the Aristocob. This product has a removable bowl from corn wood mounted onto an aluminium stem. Because of the fragility of the soft wood the Aristocob is supplied with two spare bowls. The pipe bowls are produced by the Missouri Meerschaum Company that brings the ordinary corn cob pipes on the market. The pipe is available from mid 1970 and will remain in production until about 1980. This product gets its popularity from the taste of the corn cob core that is characteristic and cannot match with any other material. The appearance of the wood gives the corn pipe not a luxury appearance.

Another successful invention is the brand Yello-Bole (Fig. 8a-d) that was launched by the U.S. Kaywoodie pipe factory. As a brand name the Yello-Bole was already in use from 1932 for the so-called rejects that were not sold under main brand name Kaywoodie. The Yello-Bole system pipe soon became popular under a broad but little potential circle of smokers. The patent is granted in 1956 to the man who developed the pipe Samuel L. Atkins from New York. Production started by Penacook in New Hampshire. Ten years later they launched a second version under the name Yello-Bole airograte, for which patent was obtained in 1966. This pipe also appeared on the European market, where the added inscription London Finished should gave the pipe a quality look. Like the Dr. Grabow, the Yello-Bole has a strongly flattened stem, however, the cooling fins are not only located at the upper side of the stem, but run all around. The aluminium casting is clearly better, mainly because no finish paint is applied.

In a nutshell, in the United States the Falcon pipe stood at the top, with a worthy second the system pipes marked Dr. Grabow and the brand Yello-Bole. Yet these two brands did not receive the fame that befalls Falcon, although both factories were economically scoring well. Due to favourable pricing, these two brands were chosen by a significant group of smokers and once used to the system, one buys the components of this mark and the purchase of another mark stays outside the question due to the non-interchangability. As a variant the Kirsten pipe remained also in production. Because its appearance is so different, this product was sold to another category of smokers.

As remaining group there is a wide range of products, who are the cheap alternative to the system pipe and never resulted in a great market success. In their introduction, such pipes benefit from the fame of the Falcon system pipe and above from the changed smoking behaviour that arose there from. The fact that many inventions used alternative materials instead of aluminium resulted often in a larger weight, while the condensing effect became smaller. This took away the positive aspect of the dry smoker. Moreover, technical problems mainly caused by leaks in the thread of the joint gave discomfort to the consumer. From the historical point of view, this remaining group is interesting because these pipes inform us about the alternative design ideas of the system pipe and the struggle of the manufacturers to gain and hold a market position.

Alternative system pipes in Europe

In Europe, the success of the Falcon pipes resulted in import of other system pipes. The brands Dr. Grabow and Yello-Bole soon became available. In addition, in the same style other products came on the market, where the American and English experiences were applied on the European continent. It is understandable that the first European findings were born in England. There the American Falcon was perfected under the inspiring leadership of David Morris, while England was further known as a leading producer of pipes with a high potential for affluent smokers.

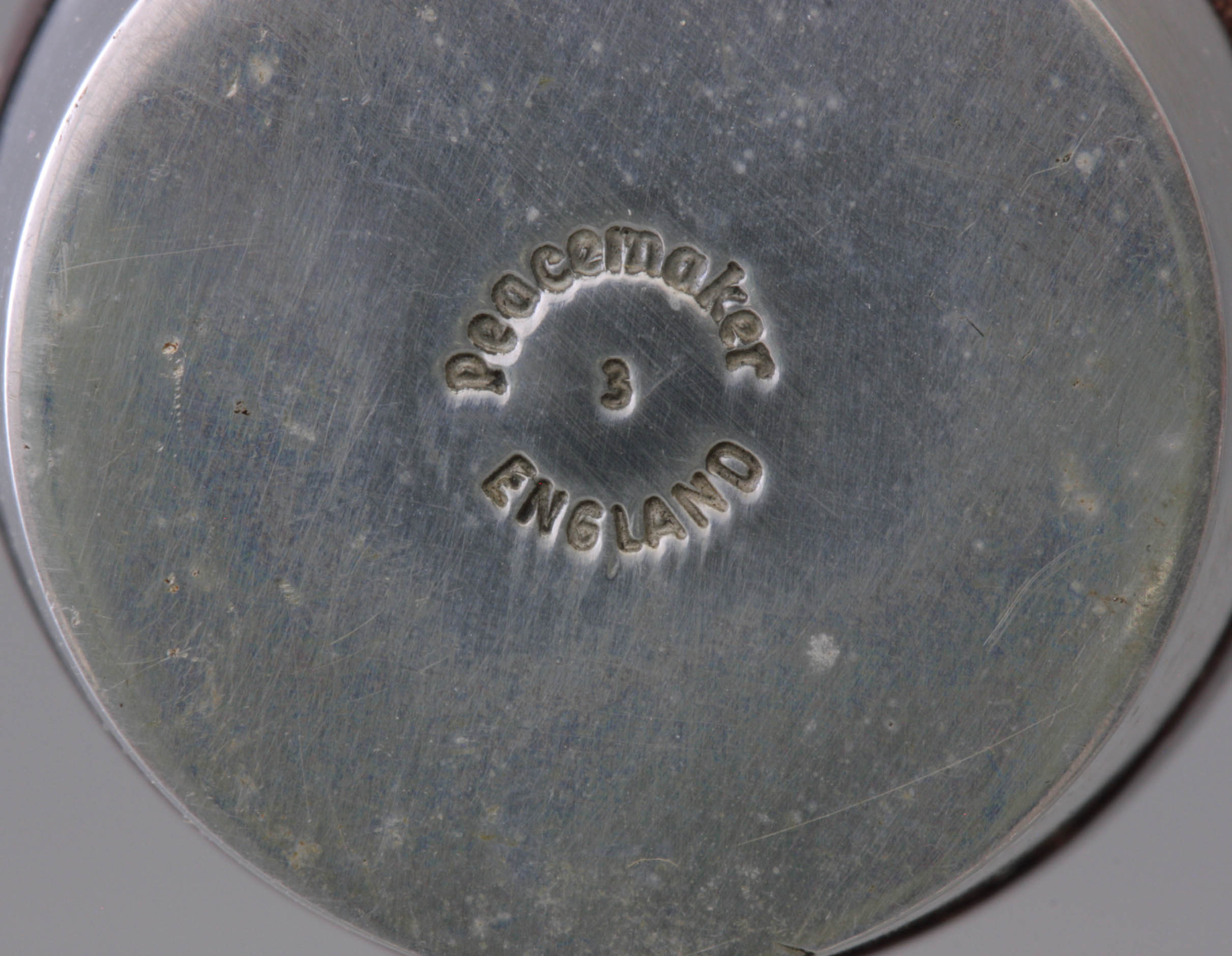

How strong the inventions were based on the American idea is demonstrated by the introduction of the Dr. Plumb Peacemaker. Again, a doctors name for the product suggests the approving of a physician who tested this pipe (Fig. 7b). An attractive variety of the Falcon pipe, is the system pipe by Britain's Best Briar that was marked with the trade mark BBB (Fig. 9a-d). At the bottom of this pipe the product carries again the addition Peacemaker, with a wink to the established brand. Technically, the pipe is identical to the Falcon, although the design is of great credit. The bent shape shows the best the special design with the hexagonal stem that provides an unexpected line going over in the black plastic mouthpiece that cares for unity in the design.

Another English variant is the Titan, which also came on the market in the 1960's. The stem is not made of aluminium, but of stainless steel. Again, it is a system pipe with changeable parts in a variation of six different bowls and three different mouthpieces. The market success is not overwhelming. Apart from the leaking bowls also the heavier stem influenced the sales negatively, therefore the instrument never got the predicate of comfortable pipe.

Besides that some trade houses initiated the production of system pipes, there also was an interest among manufacturers of lighters that started making pipes. Obviously this is in line with the machinery they used and the raw materials they applied, while the end product is sold in the same segment. The British firm Ronson launched a system pipe of which both the design and implementation was directly copied from the Falcon. The pipe has a stem of natural coloured aluminium, while a variant is produced in anodised black. The bowl is available in five different shapes, both in smooth and rustic version. With Ronson and Falcon the differences are very minimal and this Ronson system pipe should in fact be regarded as a direct copy. Differences in detail however are of little interest to stimulate the sale because the market success of the system pipe was determined by the comfort of the pipe and especially the lack of discomfort.

Under the brand name Colibri a pipe came on the market that is strictly speaking not a pipe with a removable bowl, but does stand out in this genre (Fig. 9c). The pipe has a special metal stem provided with longitudinal cooling fins, in which a complicated system is hidden, including a leather dry ring. Here the starting point is not the quick release of the heat but its storage in the fairly solid stem. Inventor Hans Lowenthal of London patented the pipe in 1964 under the name of Colibri Lighter Limited (note 7). The word lighter is therefore absolutely not related to the weight of the pipe and is in fact even misleading taking in account the almost solid aluminium stem. Again this pipe is launched from a factory for lighters which again proves that the branch of the system pipe went over to another production segment than pipes.

Somewhat delayed also on the European continent a series of system pipes was produced. The company Ropp from Saint-Claude, part of the Oppenheimer group, provided a pipe that became known under two names. For the English market the name Rocket was adopted, while on the European continent the same pipe is predominantly sold under their own brand name Ropp relax (Fig. 10a-d). The most striking feature is the hard plastic stem, which in those days was called nylon. The stem is brought out in aluminium colour as well as in red and has a profile of seven oblong placed small smoke chambers. The shape of the stem suggests cooling, but with regard to the poor heat absorption of the plastic, this pipe smokes much hotter than one would expect, and the smoker of the metal system pipe was used to.

The bowl of the Ropp pipe is supplied in two types of wood, of which cherry wood is for this factory the most characteristic. In this type of wood this factory worked for generations and the bowls were characterized by the light polished bark of the tree branch as a decorative element. In England, the Ropp company launched a grand price competition where the pipe is brought thirty percent cheaper than the Falcon (note 8). It soon turned out that the sales were temporary, because the product clearly offered less comfort than the Falcon smoker is accustomed to. For most smokers it will have remained a single purchase. Again the article takes advantage of an established design. For the real Falcon smoker the Ropp system pipe was a disappointment because the smoke remained too hot. However, for the French market the cooling effect is of less importance because the French smoke a heavier, hardly scented tobacco that gives significantly less moisture. With this type of tobacco the Ropp relax smoked much better.

In the Ropp pipe different versions are known of which it is unclear whether they were made by the same factory or that it concerns copies made by others. An example is the Rex, a pipe with a silver-plated plastic stem and a plastic mouthpiece. The thread is singular and therefore identical to the Ropp pipes although the bowls also fit on the frame of the Viking. Other French versions are the Super Twist (Fig. 11a-d) and Aero (Fig. 12a-d), both produced in France possibly under the supervision of Merton. With their English brand name they loosely follow the image of the English system pipe. Also with these products a single-screw thread is applied. The Super Twist has something remarkable in its structure: in the wood bowl base a stud is placed which regulates the passage of the smoke. The pipe is produced both in a straight as in a bent version. The Aero disappears from market in the 1970's, the Super Twist is produced over a longer time.

Another system pipe from France bears the brand name Lindbergh and again shows great similarity with the Dr. Plumb and Falcon pipes. They have both the four threads and the bowls also fit on the Falcon and the imitations thereof. Also this product comes in two versions: the Lindbergh métallique (Fig. 13a-d) and the Lindbergh Spiralo. Both pipes became considerably popular on the Dutch market. Until now the connections between the French Lindbergh firm and other producers of system pipes are still unclear. A feature of the Spiralo version is the removable plastic saucer in the bowl base with a spiral flue that increases the way the smoke has to go.

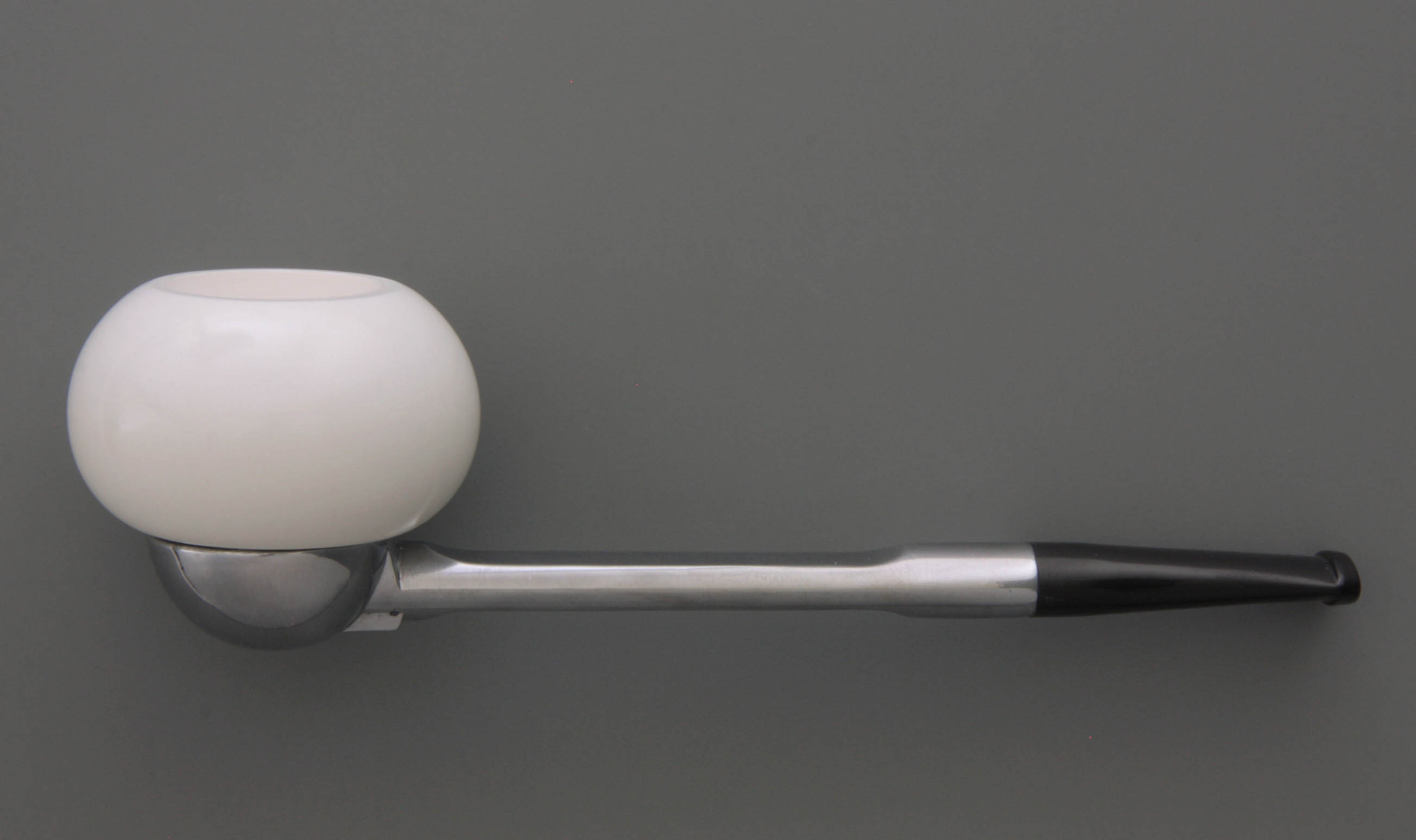

A special product of French origin is the Jima pipe (Fig. 14a-g) for export also known under the name Garland. It concerns a pipe having a different shape provided with a silver-plated or gold-plated steel metal frame, connecting a plastic mouthpiece with a plastic outer shell that houses the pipe bowl. This plastic pipe comes in different colours, with black and ivory as the most popular. More modern versions are mottled in pastel shades, whose sales stay far below any level. The inner bowl looks like meerschaum but is actually made of pressed white clay. The stem has a specific filter system which consists of a wound spiral, the so-called "filtres serpentins helicoidaux", which according to the product information is electrostatic. To access the filter the stem can be unscrewed, although in other instances a user-friendly spring system is applied. At the top of the mouthpiece we often read "Breveté France & Etranger" or "Modèle Deposé Made in France".

The Jima is also sold in the Netherlands although limited and can be compared with the Büttner pipe (note 9). The modern look of the pipe was emphasized by the manufacturer in the promotion material. The slogan speaks of la pipe de l'an 2000, which underlines that the design definitely is a generation ahead of its time.

The Italian production of system pipes is characterized by an abundant use of cheap plastic stems and low-grade briar bowls. It remains unclear to what extent the British manufacturers found therein an outlet for their poor briar bowls, that were placed on a cheap plastic frame. Both aesthetically and technically these products prove the superiority of the Falcon towards the low-grade Italian industrial products.

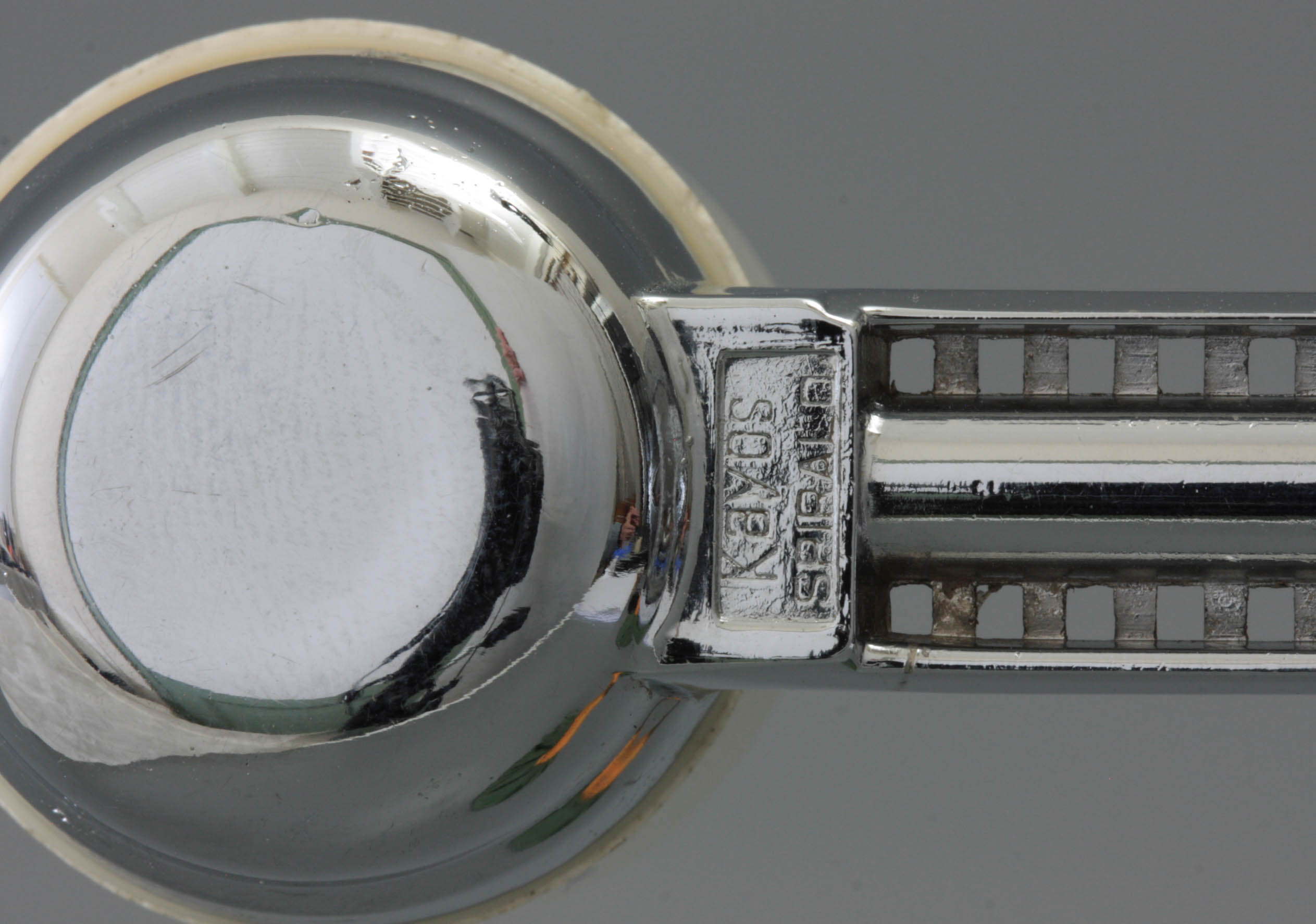

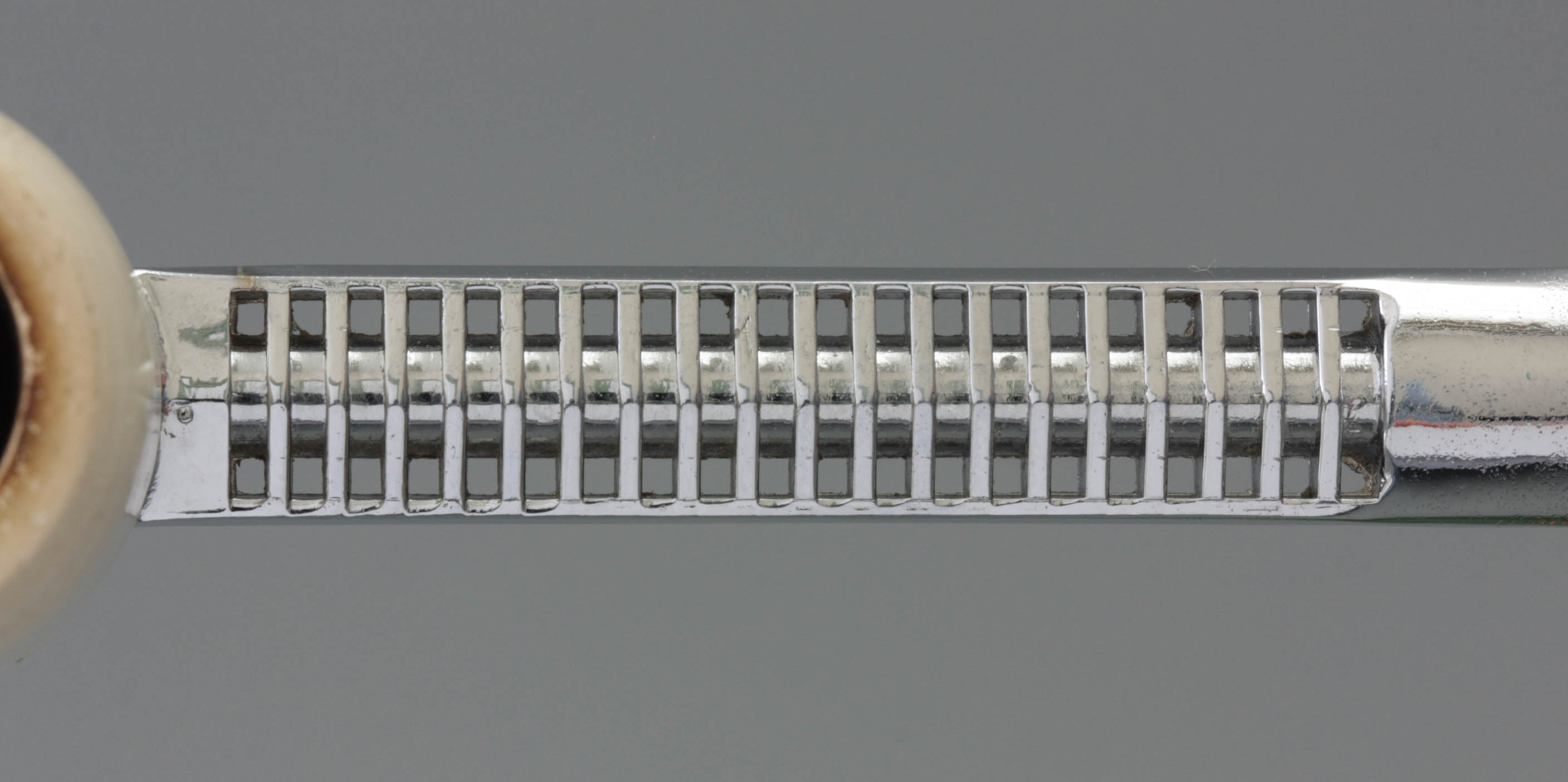

The brand name Kayos Spiralo (Fig. 15a-h) is the most famous Italian system pipe and is close to the Lindbergh spiralo. In addition, also brand names such as Gigi or Lorenzo (Fig. 16a-c) were used. The product of Lorenzo is a fine example of imitation in design and quality without passing the original. The design is extremely weak, while the material of both the plastic and the wood are poor. Lorenzo brings later a system pipe named Machavelli. Brebbia also produced a pipe with a removable bowl in around 1960 named Radiator which stays in production into the nineties. Finally there is the Eagle dry (Fig. 17a-d), an Italian product that is assembled with Viking heads. This pipe is strikingly similar to the Yellow-Bole. It is clear that copies were made over and over endlessly.

That many special designs in the removable bowl are imitations of earlier products, might be clear. Yet the differences are still evident. The quadruple threaded Falcon system is the most ingenious. This system is only applied to their brands Alco and further at Brentford, Aero and Lindbergh. However, the different marks have screw threads with different diameters, so that the bowls are not interchangeable. The most common second type is the Viking, which like all the other bowls has a single thread.

Except in England, France and Italy the fashion of the system pipe and its production also took place in other European countries. In Germany, two factories brought the system pipe: Denicotea and Design Berlin. In Denmark, the company Erik Nörding from Slangerup designed a pipe with a plastic stem and vulcanite mouthpiece that is equipped with a briar bowl. This product has no screw bowl but a push in bowl. The pricing is competitive with the Falcon and that gives the pipe its right to exist.

In addition to the direct imitations, there also exist pipes based on the Falcon system, that however exhibit a totally different appearance. Because they arise later they incorporate new achievements such as a filter in the stem of the pipe. A pipe from Sweden, for example, bears the name Brilon Popular (Fig. 18a-c), and also has a removable bowl, which is mounted on a nylon base which in turn is connected to a circular stem. In the bowl shaped base a slice of absorbent paper can be placed, which absorbs the first moisture. Obviously this idea is copied from the dry ring of Falcon. The stem itself offers space for a second filter to purify the smoke. The appearance of this Swedish pipe is more traditional and in the style of the current briar pipe. That the manufacturer did not have a well-developed sense of designing is proved by the shape of the mouthpiece that should have been slightly curved instead of straight.

How international the phenomenon of the system pipe had become is proved by the Japanese firm Tsuge that brings a pipe on the market with a separate bowl, but not equipped with a screw mount but with a clamping system. These pipes have an extra long paper filter placed in the hollow stem that leads to the mouthpiece. In this way, the liquid in the smoke is absorbed.

The system pipe in present time

By the end of the twentieth century, the boom of the system pipe is over. In fact, only the Falcon and Kirsten outlived their time. On occasion, manufacturers continued to try their luck and bring a system pipe with a new invention in the spotlight. Sometimes it concerns a variation on something that already existed, other times there really is an innovation but mostly in a moderate form. Interest in the dry smoker is gradually pushed into the background and is replaced by the filter pipe that became standard in many countries. Thus the system pipe complements the range as an alternative for smokers who experience nuisance of excessive fluid in a pipe.

At the end of the twentieth century, two new products appear on the market, directly copied from the system pipe, but showing a new design idea. The first is the Future 2000 made in Germany (Fig. 19a-d), a product also referred to as Sumerler. The pipe is launched in 1998 and promotes pipe smoking in the new millennium. The starting point for this pipe is again the removable bowl, but now not with a broad threaded ring but a thin one anchored in the bowl. This screw is placed in the spherical end of a metal stem in the way the Kristen pipe had some fifty years earlier. As the product is developed in Germany, the stem is provided with the well known filter system with a nine millimetre diameter. The mouthpiece is made of acrylic in glossy black or imitation amber. The pipe comes in a variety of conservative colours in which brown and Bordeaux dominate. The stem is always provided with a screen printed inscription "Future 2000", in accordance to the period in digital characters.

The bowl of the Sumerler is turned in briar in forms that do not belong to the classical shape range. They are more based on the bizarre geometric forms of some Falcon pipes. Except in wood, there are different designs in smooth and drilled Turkish meerschaum. With their cowardly form these meerschaum bowls do not really match with the modernist look of the metal stem. The Future 2000 does not result in a market success. The pipe is too heavy in weight and leverage makes smoking the pipe between the teeth uncomfortable. With this product, the problem of the Kirsten pipe from the thirties is back; actually the Future 2000 has more in common with the Kirsten than with the Falcon. The name seems to have been copied from the slogan of the Jima, who thirty years earlier, already spoke of the pipe of the year 2000.

Simultaneously with the Future 2000 the Dauphine appears on the market (Fig. 20a-e), launched by the factory Ewa in the French Saint-Claude. In fact, it is not so much of a system pipe, but rather of a three-part pipe, consisting of a separate briar bowl, a stem of a different type of wood and an acrylic mouthpiece. With this product, the manufacturer has once again opted for the traditional bore without filter as the French smoker prefers. The bowl has a cylindrical pin that clamps in the stem. At the base a rubber ring is fitted intended to counteract any false draft. In fact the rubber ring barely does its task between the two parts. The pipe comes in different colours: the bowls are brown, black, red or green, the stem is sometimes made of pale wood, in other cases painted glossy black. Also in the mouthpieces we see colour nuances, which the modern acrylic enables to give the product a cheerful look. The brand name is embossed in the wood of the stem.

Shortly afterwards a revived interest in the Falcon comes from a different angle. The Turkish pipe trader and exporter Levent Yügüzür from Iskezir brings a new system pipe à la Falcon on the market (Fig. 21a-d). The system of the removable bowl is maintained, but given the place of manufacture, these are only supplied in meerschaum. Due to the fragile nature of the meerschaum at the bottom of the bowl a plastic base was affixed, which is invisible in the fastening plate of the stem, while the flexibility of the plastic also prevents false draft. The finish of the stem looks like aluminium but it is made of plastic, which is very cleverly painted so they cannot be distinguished from aluminium. On the underside of the stem, at the connection of the bowl, you can read the EP mark. The hole in the meerschaum bowl gave some initial problems. When launched the pipe had a single hole drilled in that permitted the smoke into the lower chamber. After two years the bottom of the bowl got a larger opening in which a separate circular stone is placed, which has four small openings as smoke tubes. These small openings give fewer risk that ashes and tobacco crumb falls in the base of the pipe. Advantage of the pipe is unmistakably the beautiful highly porous meerschaum that ensures a maximum of absorption available in a wide variety of shapes. The plastic stem does however not stimulate the desired condensation and those smokers who draw stronger from the pipe may get lots of moist in the stem.

In the 21st century the first generation of Falcon smokers is almost extinct. As product Falcon has known multiple phases. From ultra modern invention, it drops down to a pipe for a wide audience for whom the dry smoker is a popular must. Slowly on the article becomes bourgeoisified and fitting the conservative smoker. In the late eighties the Falcon is considered as old-fashioned but around the millennium a certain revival comes. The Kirsten pipe, which always remained on the market, has experienced a similar life, though this particular design never became so popular. Around the turn of the century, new young smokers are interested in original designs. The futuristic look of the pipe fits with their penchant for the fifties, a period which is now perceived as hot. These young smokers are the new customers, though the rage of the past will never come back. The number of pipe smokers has fallen sharply and this scarce juveniles form a select group that has no potential in creating an economic stimulus.

For the Falcon of current owner Merton of London remains a worldwide demand to some extent. The firm has no interest in innovation except for a few adjustments. Thus, a new finishing of the bowl is made, known under the name of dress, carried out in matt black. With this initiative, the manufacturer gives the product a more stylish look. Sometime later, the brown base colour for the metal stem extended with some fresh modern colours like red, yellow, blue and purple. These changes should give a guarantee for the new, modern look of the pipe. Meanwhile there seems to be more than 44 million Falcon pipes sold while the number of look-alikes is incalculable. This is definitely a record sales result for a particular pipe model. The name Falcon has finally became synonymous with the lightweight system pipe and compared with Falcon's huge market success the countless other inventions are no more than mayflies.

© Don Duco, Pijpenkabinet Foundation, Amsterdam – the Netherlands, 2006.

Illustrations

1a-e. The Kirsten pipe with the rusticated black bowl and stem with square diameter including a version with a smaller smooth bowl in polished briar. USA, Seattle (Washington), Kirsten Pipe Company Inc., 1975-1985.

Amsterdam, Pijpenkabinet collections Pk 398a, Pk 17.641

2a-e. System pipe known as Bryson with an aluminium stem with interior and screw on bowl made from pressed briar dust painted with imitation wood grains. USA, Palo Alto (California), Briarwood Corporation, 1960-1965.

Amsterdam, Pijpenkabinet collections Pk 17.899

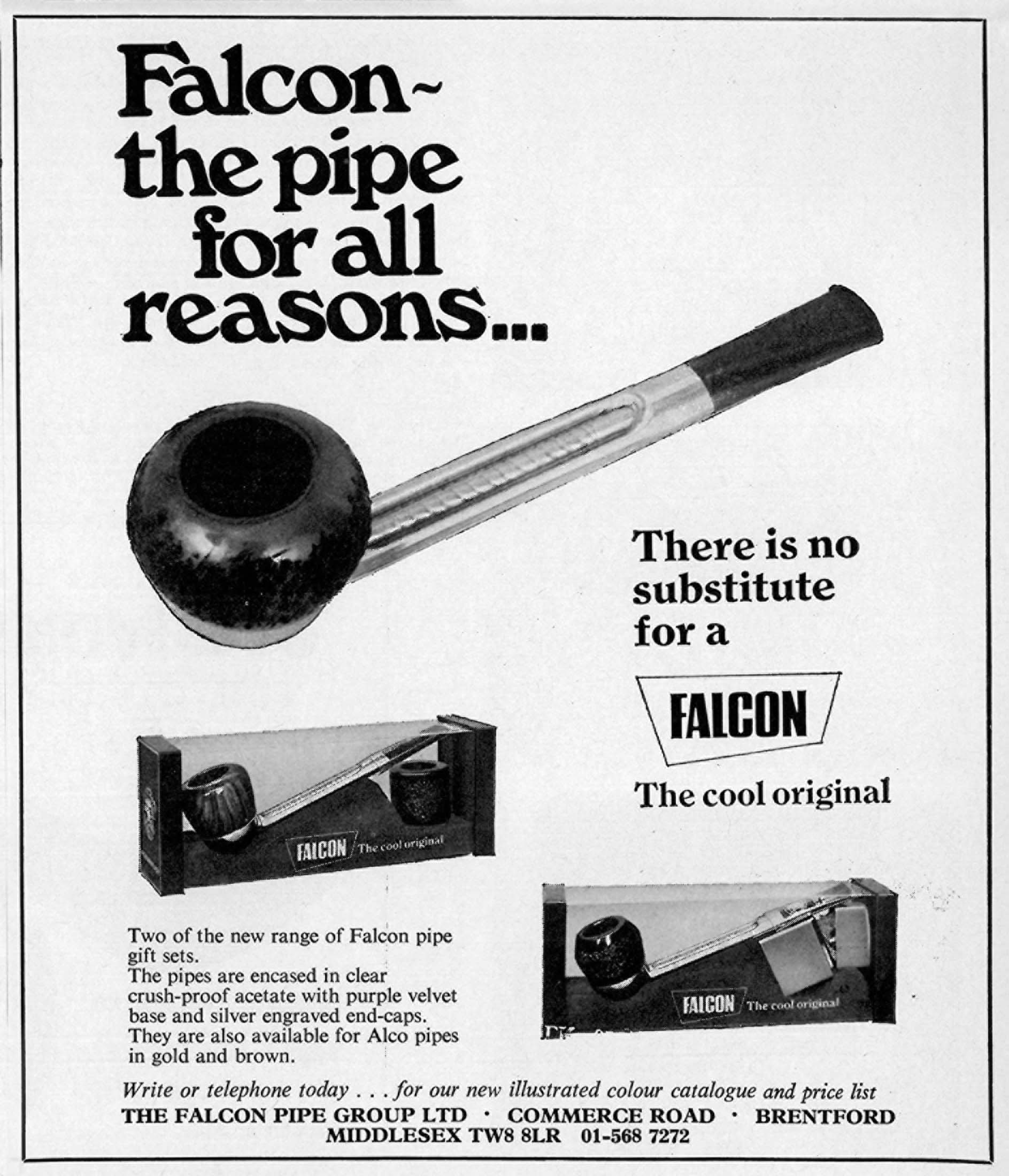

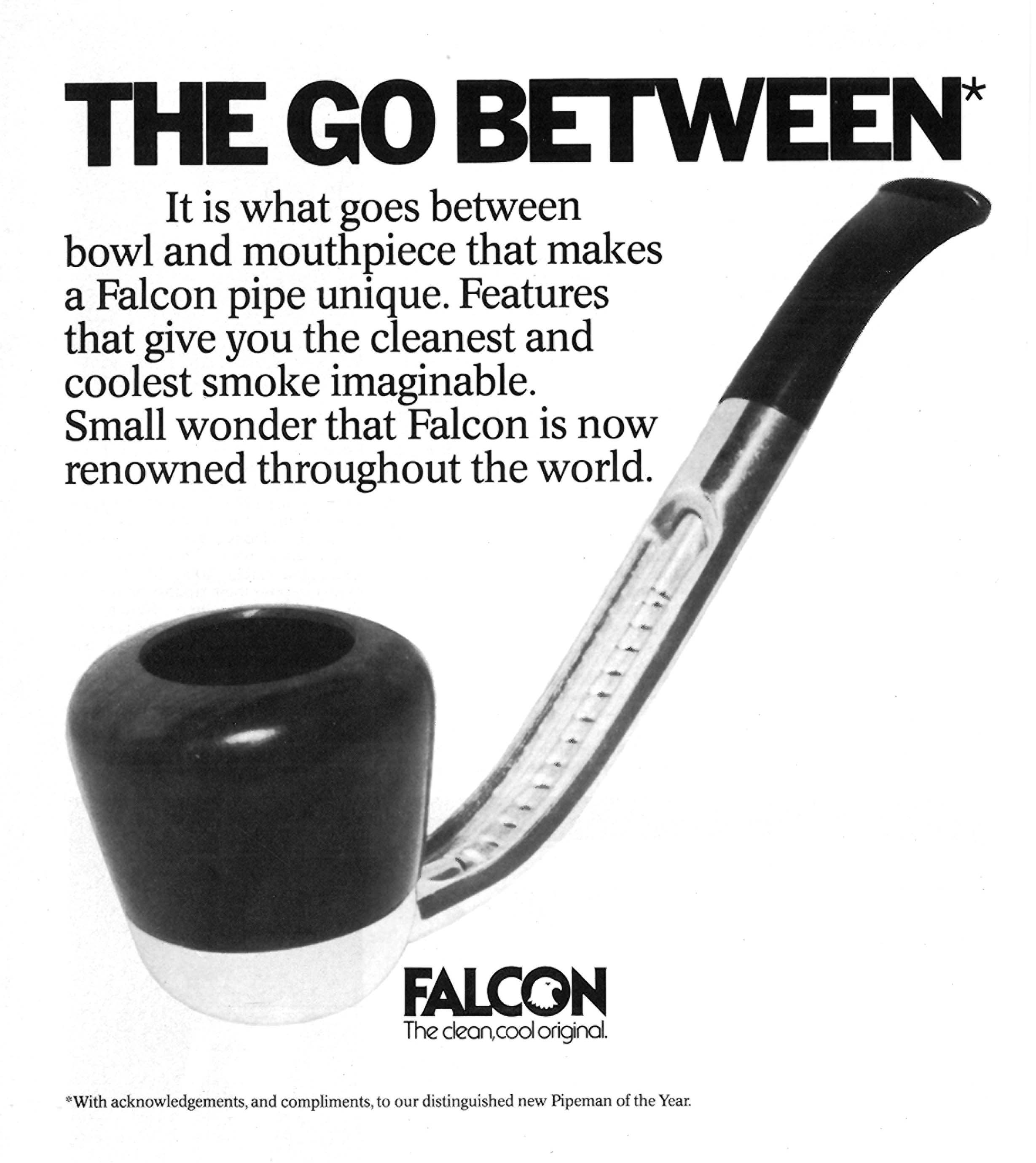

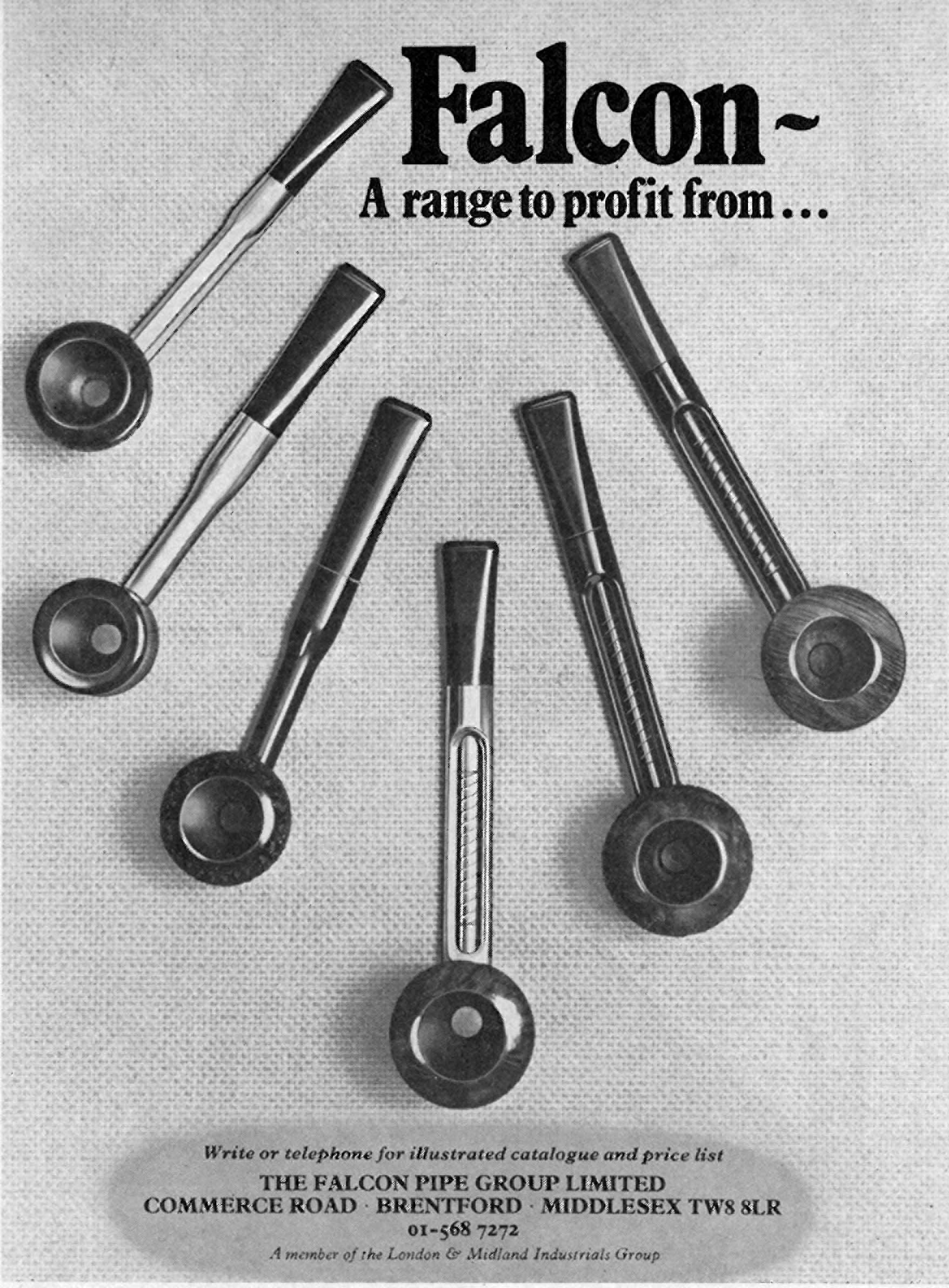

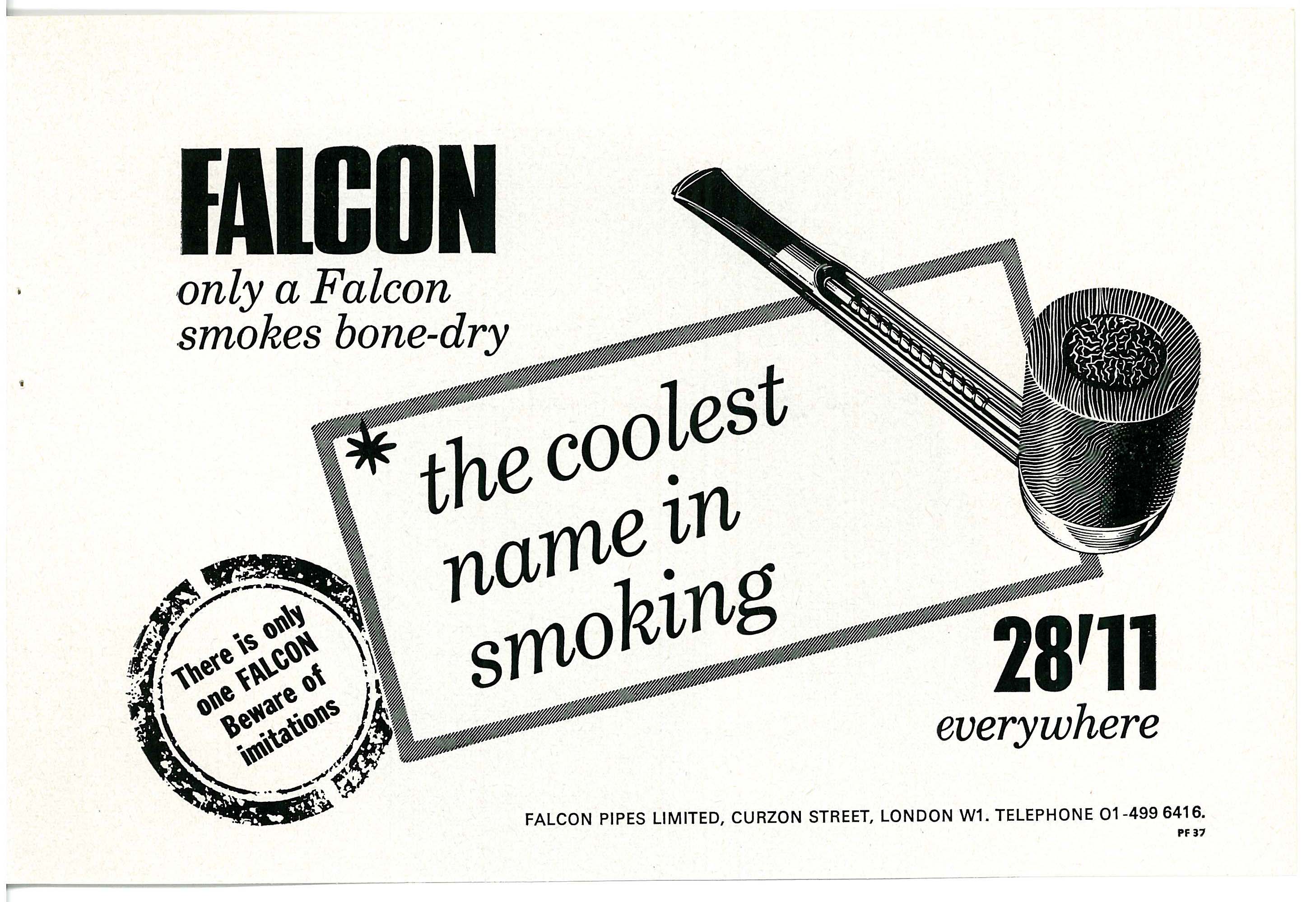

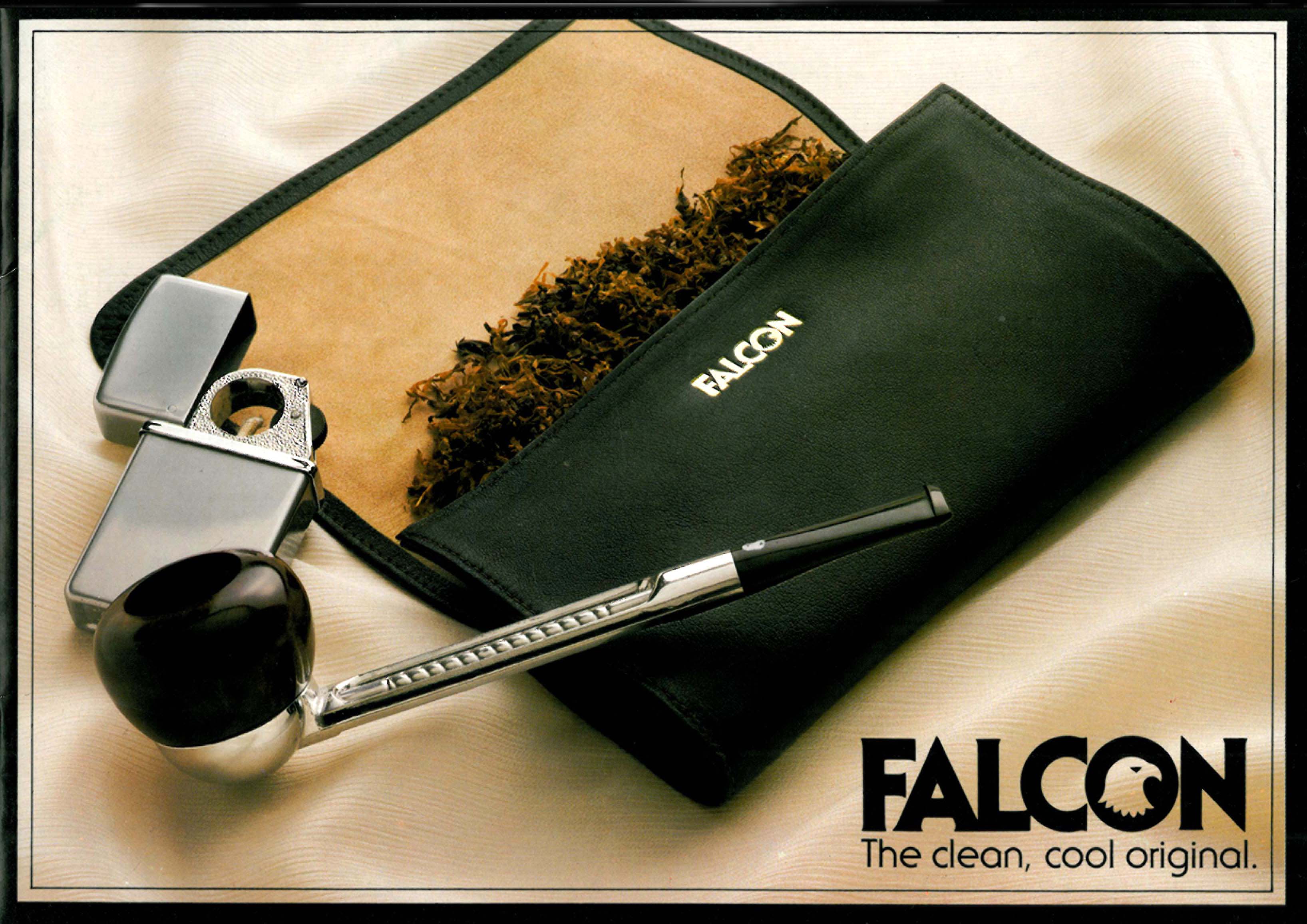

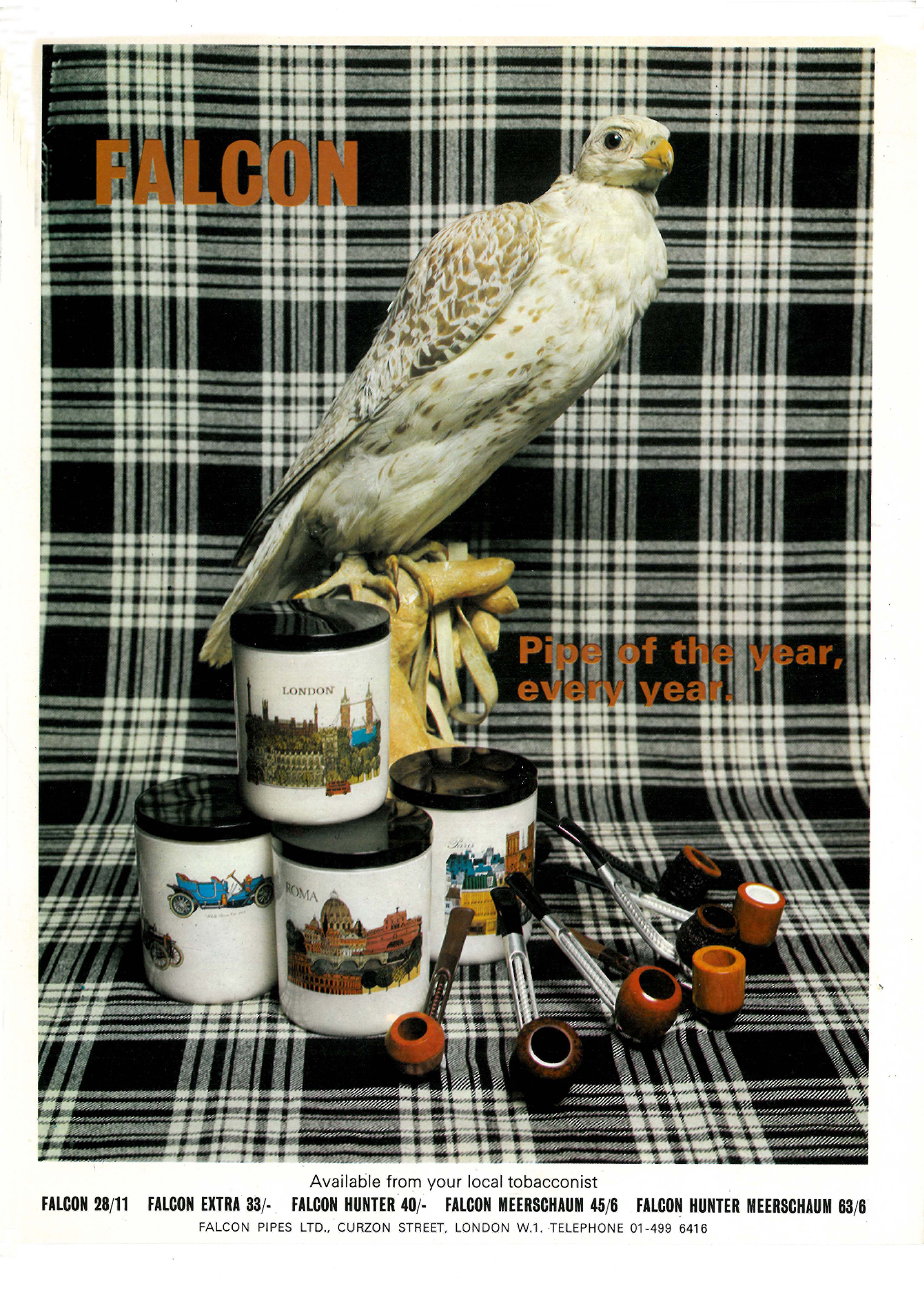

3a-h. Various old print work such as product descriptions, leaflets, advertisements and folders for the Falcon pipe. England, Brentford, Falcon Pipes Ltd., 1960-1990.

Amsterdam, Pijpenkabinet collections documentation

4a-g. The characteristic Falcon pipe including details showing the twisted stem, the mark the eagle's head on the mouthpiece and the marks and codes on the base of the bowl. England, Brentford, Falcon Pipes Ltd., 1960-1975.

Amsterdam, Pijpenkabinet collections Pk 227

5a-d. A variety on the Falcon called Alco, a new design with smaller size and sportive imago finished in coloured aluminium, including the hygienic cover on the stem end. Here with bowl shape spool. England, Brentford, Falcon Pipes Ltd., 1960-1970.

Amsterdam, Pijpenkabinet collections Pk 820b

6a-c. The Falcon International Filter Pipe from 1977 for a healthier smoke because of the filter system, the metal of stem and bowl base is covered with plastic. England, Brentford, Falcon Pipes Ltd., 1977-1980.

Amsterdam, Pijpenkabinet collections Pk 12.444

7a. The American Dr. Grabow Viking, a serious imitation of the Falcon pipe with the cooling ribs on the top of the stem, patented in the USA in 1954. USA, 1960-1970.

Amsterdam, Pijpenkabinet collections Pk 3.289

8a-c. The famous Yello-Bole by the Kaywoodie firm, patented in 1956. Note the beautiful cooling ribs going round the stem. USA, New Hampshire, Penacook, 1960-1970.

Amsterdam, Pijpenkabinet collections Pk 4.848

9a. A very special design is shown in this system pipe called Peacemaker having an up going stem with particular swing. England, London, Britain's Best Briar, 1965-1975. Including two advertisements for the English Titan (Fig. 9b) and the Colibri (Fig. 9c), the first a variety on the Falcon, the second with a completely different design and a complicated system in the metal pipe stem.

Amsterdam, Pijpenkabinet collections Pk 18.407

10a-c. The Ropp relax system pipe with a cherry wood bowl showing the skin on the wood on the outside placed on a red plastic base and stem with seven mini smoke chambers. France, Saint-Claude, Ropp, 1960-1970.

Amsterdam, Pijpenkabinet collections Pk 18.406

11a-b. One of the many less perfect system pipes, the Super Twist, made according to the concept of Falcon at one of the competing factories. The aluminium still has the perfect quality. France, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 2.773a

12a-b. A product of the middle quality marked Aero. Mind the screw in the bowl interior for air regulation. France, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 4.693

13a-e. The Lindbergh with flat stem having a row of rectangular openings along the sides of the stem, produced in white metal and in brown like the Falcon. France, Saint-Claude, Lindbergh, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 2.327

14a-e. System pipe of the mark Jima with a frame stem with filter compartment, the mouthpiece and the bowl of hard plastic, the bowl interior in ceramic. France, Saint-Claude, Berrod-Regad-Groupe, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 2.862, Pk 11.905abce

15a-f. The Kayos-Spiralo from Italy, a cheap system pipe of inferior quality produced with meerschaum bowl and in briar wood finishing. Italy, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 814ab, Pk 7.473

16a-c. An extremely cheap system pipe by Lorenzo, the stem is not only of a poor quality plastic but especially the modelling is too rough so that the pipe became inelegant. Italy, Gallarate, Lorenzo, 1975-1980.

Amsterdam, Pijpenkabinet collections Pk 2.301

17a-c. The Eagle Dry, a cheap Italian frame that can be fitted with briar bowls from the brand Yello-Bole, that also inspired the design for this pipe. Italy, 1975-1980.

Amsterdam, Pijpenkabinet collections Pk 3.734

18a-b. The Brilon popular, a system pipe with detachable wooden bowl and plastic base and stem. On the bottom of the bowl an absorbing ring and in the stem a ditto filter. Sweden, 1965-1975.

Amsterdam, Pijpenkabinet collections Pk 292

19a-d. The Future 2000 or Sumerler consisting of an aluminium stem with filter system and a geometrical bowl with vice. Germany, Utku Sümerler, 1998-1999.

Amsterdam, Pijpenkabinet collections Pk 822a-c

20a-e. Tobacco pipe with a detachable bowl on a wooden base brought under the name Dolphin. France, Saint-Claude, EWA, 1998-2000.

Amsterdam, Pijpenkabinet collections Pk 1.030ab

21a-d. System pipe of the type Falcon with a plastic stem and a block-meerschaum bowl, on the stem the mark EP. Turkey, Iskezir, Levent Yügüzür, 2001.

Amsterdam, Pijpenkabinet collections Pk 301

Notes

1. Also called Works. The products of this period are marked on the boxes with D.M.W Inc.Chicago Ill.

- Otto Pollner, ‘Patented pipe systems, then and now’, The Pipe Year Book 1999, Paris, 1999, p 119.

- G. Guyot, Les pipiers Français, Paris, 1991, p 57.

- Production enlargement in Ireland by Presbar that produces the stems. The Irish bowls were made in Leixlip by Hunt Associates Ltd, a joint venture between George Hunt and some Irish businessmen.

- Charles Graves, A pipe smoker’s Guide, London, 1969, p 105 a.f.

- Alexis Libaert & Alain Maya, The Illustrated History of the Pipe, London, 1994, p 202.

- US patent D204.652.

- Jacques P. Cole, ‘The dangers of new ideas and trends’, The Pipe Year Book 1996, Paris 1996, p 77.

- Don Duco, Büttner, een rookmachine van een alternatief materiaal (Büttner, a smoke machine made from an alternative material), Amsterdam, 2002.